Silicon-doped bismuth telluride-based memory material for phase-change memory and preparation method of silicon-doped bismuth telluride-based memory material

A storage material, silicon doping technology, applied in the field of microelectronics, can solve the problems of high write current, erase current, amorphous Si resistance, etc., to reduce write current and erase current, small crystalline resistance, and reduce current pulses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the Si-doped BiTe-based storage material of the present invention can adopt any one of methods such as sputtering method, chemical vapor deposition method, evaporation method, atomic layer deposition method, metal organic compound thermal decomposition method or laser assisted deposition method. A preparation method.

[0035] In the embodiment of this paper, the method of magnetron sputtering is used to prepare Si-doped Bi 2 Te 3 film. First, a Bi with a diameter of 100 mm and a thickness of 5 mm was prepared. 2 Te 3 Target material, the purity of the target is 99.999% (atomic percentage), and the Si sheet with a size of 2*10mm is evenly pasted on the Bi 2 Te 3 On the alloy target, the atomic ratio of Bi to Te is changed by adjusting the sputtering pressure, and the doping amount is changed by changing the number of Si flakes. Then, the method of magnetron sputtering is used, and Ar gas with a purity of 99.999% is introduced during sputte...

Embodiment 2

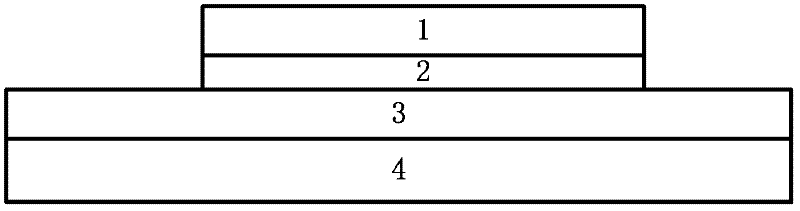

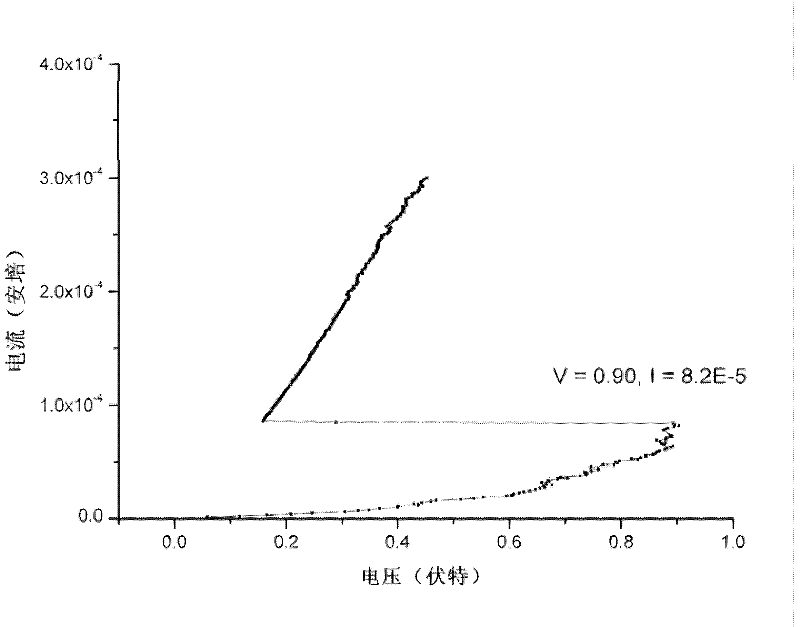

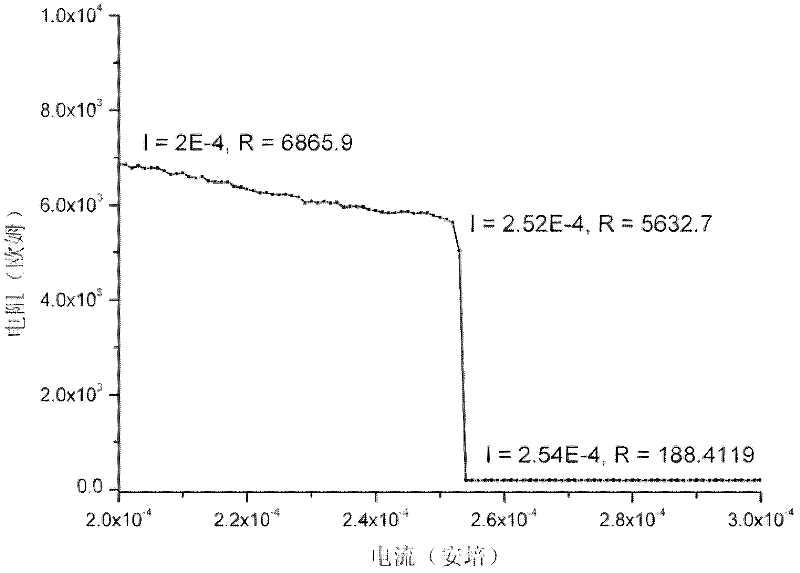

[0038] In order to test the electrical properties of BiTe-based storage materials conveniently, such as figure 1 The simple three-layer structure shown in the figure, 1 is the upper electrode, and 2 is the phase change functional material Bi x Te y Si 100-(x+y) , 3 is the bottom electrode, 4 is the substrate. Among them, the intermediate storage material adopts different compositions of Bi x Te y Si 100-(x+y) film material. The dimensions of each film layer are as follows: the substrate is covered with a layer of SiO 2 thin-film Si sheet; the bottom electrode is TiW with a film thickness of 150nm; the middle is a phase-change functional material with Bi 40 Te 54 Si 6 For example, the thickness is 60nm; the upper electrode is TiW, and the film thickness is 120nm; the plane size of the three-layer structure is 60μm*80μm. Use a probe station to conduct current-voltage (I-V) tests on the three-layer structural unit of the above structure, let the two probes touch the upp...

Embodiment 3

[0041] Bi 40 Te 50 Si 10 , carry out the X-ray diffraction test in the deposited state and after annealing, the test results are as follows Figure 4 shown. In the figure, a is the as-deposited state, and b is the polycrystalline state after annealing at 300°C for 3 minutes. It can be seen from the XRD spectrum that the Si-doped BiTe-based phase-change memory material exhibits a single triangular structure in the crystalline state.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com