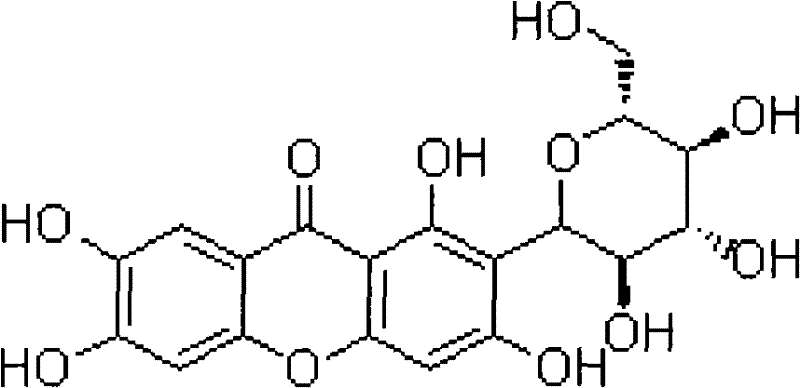

Preparation method of mangiferin

A mangiferin and mixed solution technology, applied in the direction of organic chemistry, can solve the problems of safety impact, increased production cost, long production cycle, etc., and achieve the effect of avoiding resin pretreatment, saving production cost and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

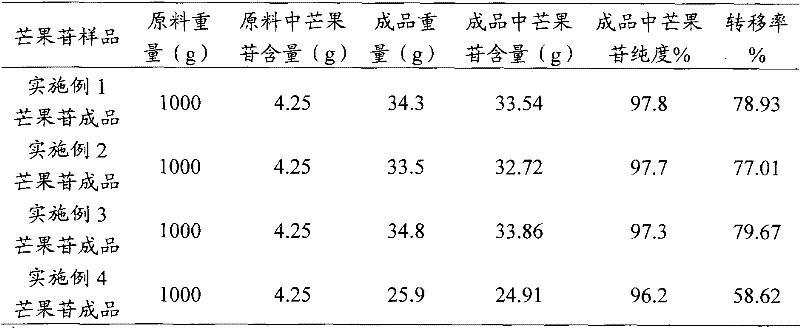

Embodiment 1

[0033] Embodiment 1: the preparation method of mangiferin of the present invention prepares mangiferin

[0034] Mango leaves 1Kg, dried, crushed into coarse powder, added 10L of methanol and water mixed solution with a volume ratio of 8:2 to extract twice, each extraction for 2 hours, filtered, combined filtrates, concentrated under reduced pressure to 1L volume, relative density is ρ = 1.13 (60°C), add 1L of ethyl acetate to extract twice, continue to recover the water under reduced pressure to 0.5L, the relative density is ρ = 1.20 (60°C), add hydrochloric acid to adjust the pH value to 1, and let it stand for crystallization 24 hours. Take the crystallization solution and centrifuge, discard the supernatant, wash the precipitate once with 0.5L of water, filter with suction, wash the filter cake with 1L of acetone twice, filter with suction, dry the filter cake at 60°C for 2 hours, and obtain the crude product of mangiferin 38.2 gram. Take the crude product, add 3.8L of ac...

Embodiment 2

[0035] Embodiment 2: the preparation method of mangiferin of the present invention prepares mangiferin

[0036] Mango leaves 1Kg, dried, crushed into coarse powder, added 15L of propanol and water mixed solution with a volume ratio of 7:3 for extraction 3 times, each extraction for 1 hour, filtered, combined filtrates, concentrated under reduced pressure to 1L volume, relative density ρ = 1.15 (60°C), add 3 L of butyl acetate to extract 3 times, continue to depressurize and recover the water to 0.5 L volume, the relative density is ρ = 1.23 (60°C), add hydrochloric acid to adjust the pH value to 3, and let it stand for analysis. Crystal 12 hours. Take the crystallization solution and centrifuge, discard the supernatant, wash the precipitate once with 0.5L water, filter with suction, wash the filter cake with 1L acetone for 3 times, filter with suction, dry the filter cake at 60°C for 4 hours, and obtain crude mangiferin 37.3 gram. Take the crude product, add 3.7L of acetone-...

Embodiment 3

[0037] Embodiment 3: the preparation method of mangiferin of the present invention prepares mangiferin

[0038]Mango leaves 1Kg, dried, crushed into coarse powder, added 10L of ethanol and water mixed solution with a volume ratio of 8:2 to extract 3 times, each extraction for 2 hours, filtered, combined filtrates, concentrated under reduced pressure to 1L volume, relative density was ρ=1.14 (60°C), add 1L of mixed solvent of ethyl formate and ethyl acetate to extract twice, continue to decompress and recover the water to 0.5L volume, relative density is ρ=1.25 (60°C), add hydrochloric acid to adjust pH Value 2, static crystallization for 18 hours. Take the crystallization solution and centrifuge, discard the supernatant, wash the precipitate once with 0.5L of water, filter with suction, wash the filter cake with 1L of acetone twice, filter with suction, dry the filter cake at 60°C for 3 hours, and obtain the crude product of mangiferin 39.4 gram. Take the crude product, add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com