Titanate luminescent material and preparation method thereof

A luminescent material and titanate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of insufficient luminous brightness, and achieve the effects of simple process production, wide adaptability and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

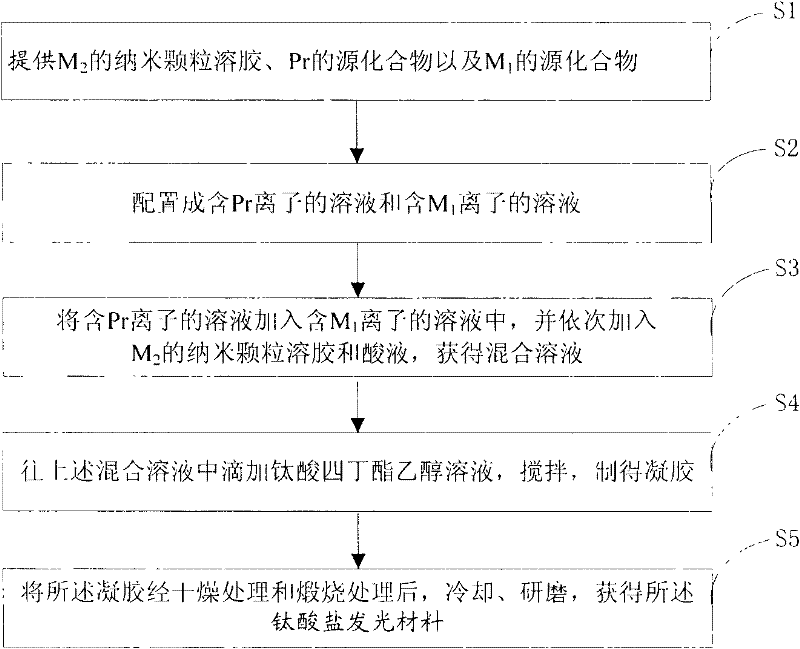

[0025] The preparation method of the above-mentioned titanate luminescent material, such as figure 1 As shown, the preparation process is as follows:

[0026] Step S 1. According to the general chemical formula M 1 TiO 3 · x Pr · yM 2 The stoichiometric ratio of each element in the given M 2 The nanoparticle sol, the source compound of Pr and the M 1 source compound; among them, M 1 At least one of Ca, Sr or Ba, M 2 It is at least one of Ag, Au, Pt or Pd nanoparticles, and the value of x is 5×10 -5 ~1×10 -2 , the value of y is 5×10 -7 ~1×10 -4 ;

[0027] Step S2, combining the source compound of Pr and M 1 The source compounds were dissolved in ethanol or water respectively, and configured as a solution containing Pr ions and a solution containing M 1 a solution of ions;

[0028] Step S3, the solution of Pr ions in the above configuration is divided into 5×10 -5 : 1~1×10 -2 : 1 molar ratio, added to the containing M 1 ions in solution; subsequently adding the M...

Embodiment approach 1

[0039] 1. Preparation of Pt nanoparticle sol

[0040] Weigh 5.18mg chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) be dissolved in the deionized water of 15.2mL; After chloroplatinic acid dissolves completely, take by weighing 8.0mg sodium citrate and 12.0mg sodium dodecylsulfonate, and dissolve into chloroplatinic acid aqueous solution under the environment of magnetic stirring Medium; Weigh 3.8mg of sodium borohydride and dissolve it in 10mL of deionized water to obtain a concentration of 1×10 in 10mL -2 mol / L sodium borohydride aqueous solution; under the environment of magnetic stirring, the ratio of the amount of the reducing agent to the metal ion substance is 4.8:1, add 4.8mL sodium borohydride aqueous solution dropwise to the chloroplatinic acid aqueous solution, and then continue Reaction for 45min, the content of 20mL Pt is 5×10 -4 mol / L Pt nanoparticle sol.

[0041] 2. Preparation of calcium praseodymium titanate phosphor doped with Pt nanoparticles

[0042] 1) Using...

Embodiment approach 2

[0049] 1. Preparation of Ag nanoparticles sol

[0050] Weigh 17.0mg silver nitrate (AgNO 3 ) into 19.5 mL of deionized water; when the silver nitrate was completely dissolved, weigh 60 mg of sodium citrate, and dissolve it in the silver nitrate aqueous solution under magnetic stirring; dilute and prepare 10 mL of hydrazine hydrate with a concentration of 0.1 mol / L Solution; under the environment of magnetic stirring, according to the ratio of reducing agent to metal ion substance amount of 0.5:1, add 0.5mL0.1mol / L hydrazine hydrate solution to the silver nitrate aqueous solution at one time, and then continue to react for 25min , that is, the silver content of 20mL is 5×10 -3 mol / L Ag nanoparticle sol.

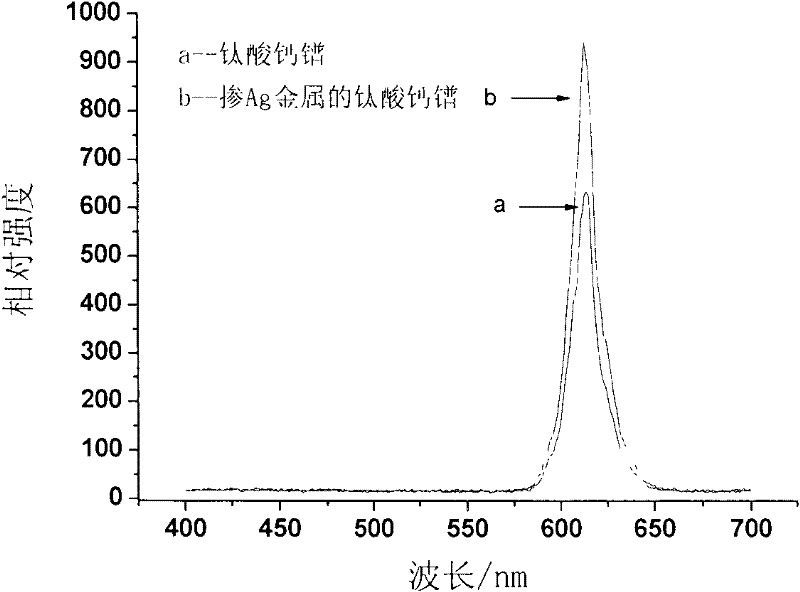

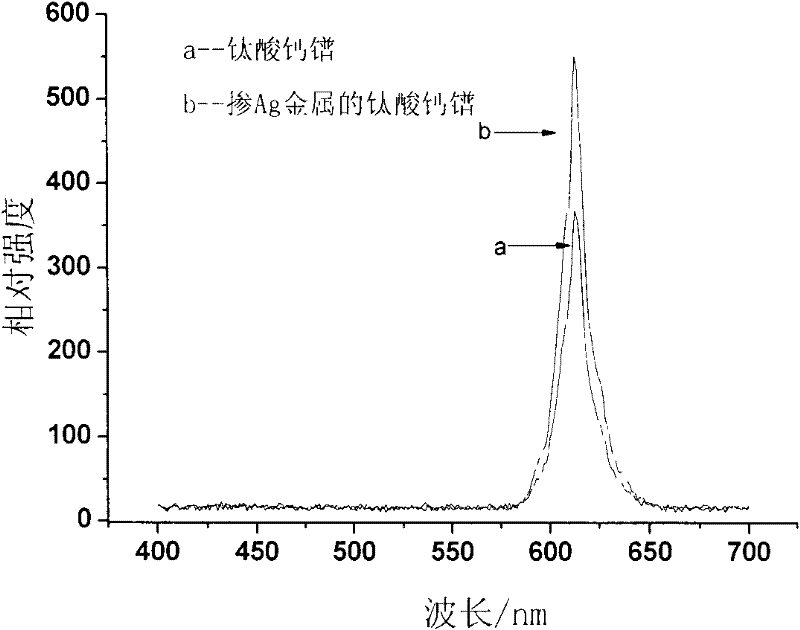

[0051] 2. Preparation of calcium praseodymium titanate phosphor doped with Ag nanoparticles

[0052] 1) Using absolute ethanol as a solvent, prepare 1.5mol / L Ca(NO 3 ) 2 ethanol solution and 5 x 10 -3 mol / L of Pr(NO 3 ) 3 weak;

[0053] 2) Press Pr 3+ and Ca 2+ The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com