Preparation method of nickel-based catalyst, prepared catalyst and application thereof

A nickel-based catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of small porosity, La loss, catalyst specific surface area and Pore volume reduction and other issues, to achieve excellent activity and selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

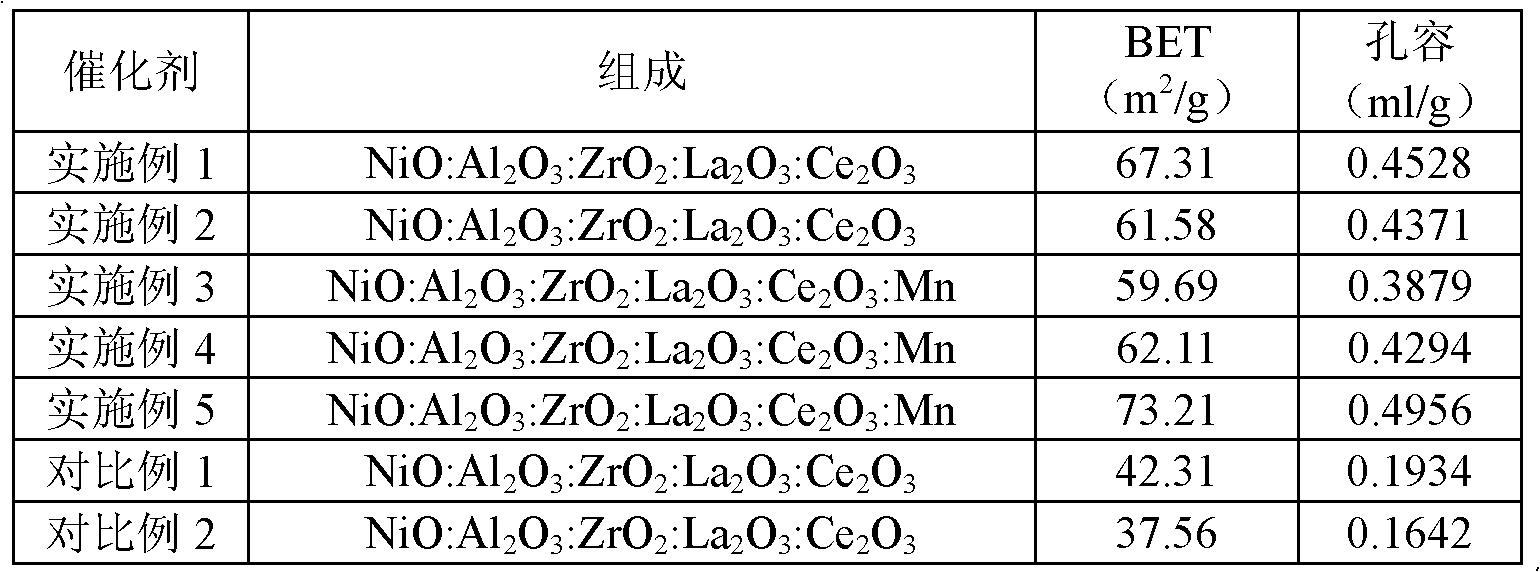

Examples

preparation example Construction

[0055] Another aspect of the present invention relates to the preparation method of above-mentioned catalyst, comprises the following steps:

[0056] (a) providing a mixed aqueous solution containing a nickel salt, an optional non-aluminum carrier metal salt, and an optional manganese salt;

[0057] (b) precipitating the mixed aqueous solution of step (a) with a precipitating agent; optionally aging; solid-liquid separation to obtain solid precipitation;

[0058] (c) mixing the solid precipitate in step (b) with a rare earth salt solution, and impregnating to form an impregnating solution;

[0059] (d) Separating the impregnation liquid from solid to liquid to obtain the impregnated solid, and forming the impregnated solid into a catalyst slurry, optionally adding aluminum sol and mixing uniformly during the process of forming the impregnated solid into the catalyst slurry;

[0060] (e) granulating and optionally drying the catalyst slurry to obtain a catalyst material;

[0...

Embodiment 1

[0112] 4.87 kilograms of nickel nitrate hexahydrate and 1.569 kilograms of zirconium nitrate were dissolved (diluted) in deionized water respectively to prepare a 15% nickel nitrate solution, and simultaneously dissolve to obtain a 15% sodium carbonate solution.

[0113] Preheat the mixed solution of nickel and zirconium metal salts and sodium carbonate solution to 80°C, co-precipitate into the reaction kettle, adjust the pH value of the precipitation to 8, filter after the precipitation, and wash to obtain the co-precipitation filter cake. Add 10 kg of deionized water to the co-precipitation filter cake for beating, add 0.133 kg of lanthanum nitrate and 0.1325 kg of cerium nitrate to prepare the solution, the pH of the slurry preparation is 5.4, soak at 85 ° C for 20 minutes, and the catalyst impregnation solution Filter to obtain impregnation filter cake, add 5 kilograms of deionized water to make a slurry in filter cake, Al 2 o 3 3.6769 kg of aluminum sol solution with a w...

Embodiment 2

[0115] Obtain coprecipitation filter cake according to the steps of Example 1, add 10 kg of deionized water to the coprecipitation filter cake for beating, add 0.0998 kg of lanthanum nitrate and 0.1988 kg of cerium nitrate prepared solution, mix evenly, and the solid content of the slurry is 15% ,, the pH of the sizing solution is 5.4, impregnated at 85°C for 20 minutes, filtered the catalyst impregnated solution to obtain the impregnated filter cake, added 5 kg of deionized water to the filter and made a slurry, added Al 2 o 3 5.5145 kg of aluminum sol solution with a weight concentration of 10%, mix evenly, and keep the solid content of the slurry at about 15%, and the obtained slurry is spray-dried at a temperature of 300°C at the inlet and 180°C at the outlet, and roasted at 960°C After 6 hours, 2.140 kg of catalyst was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com