Building exterior wall integral solidified organic heat insulation board and preparation method thereof

A thermal insulation board and overall solidification technology, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the disadvantages of rapid industrial production and production efficiency, loss of bonding and fixing effect of glass fiber cloth, difficulty in controlling the thickness of cement mortar coating and other problems, to achieve the effect of reducing the number of molds and production costs, shortening the demoulding cycle, and stabilizing the thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

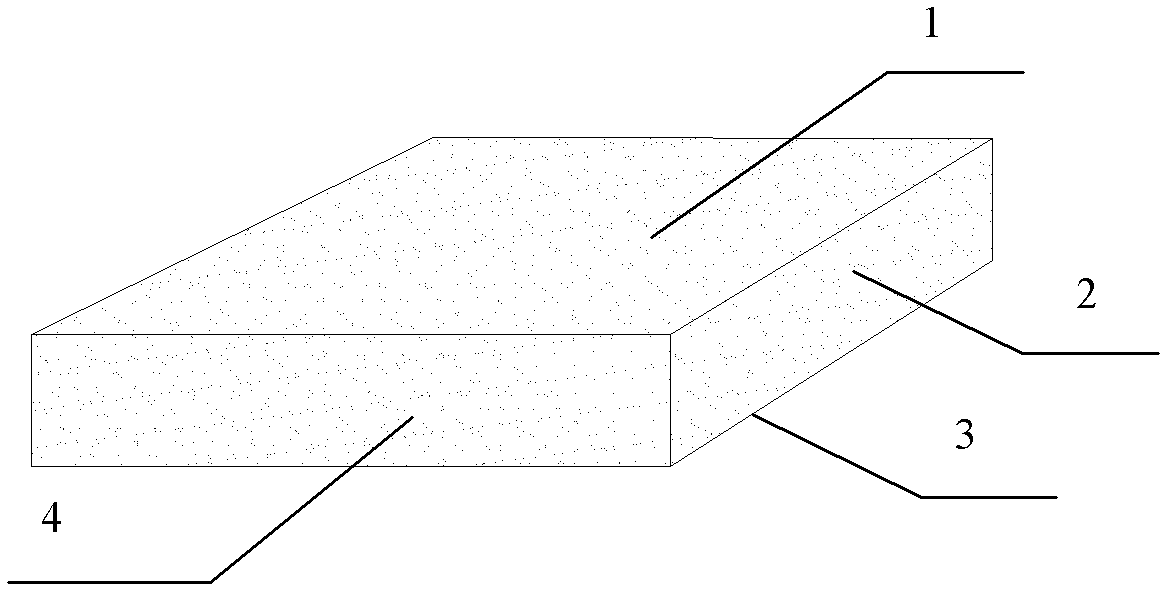

[0032] The present invention is described further in conjunction with accompanying drawing, and the manufacturing technology of this device is very clear to those skilled in the art.

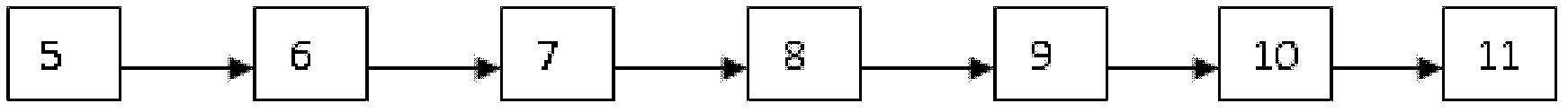

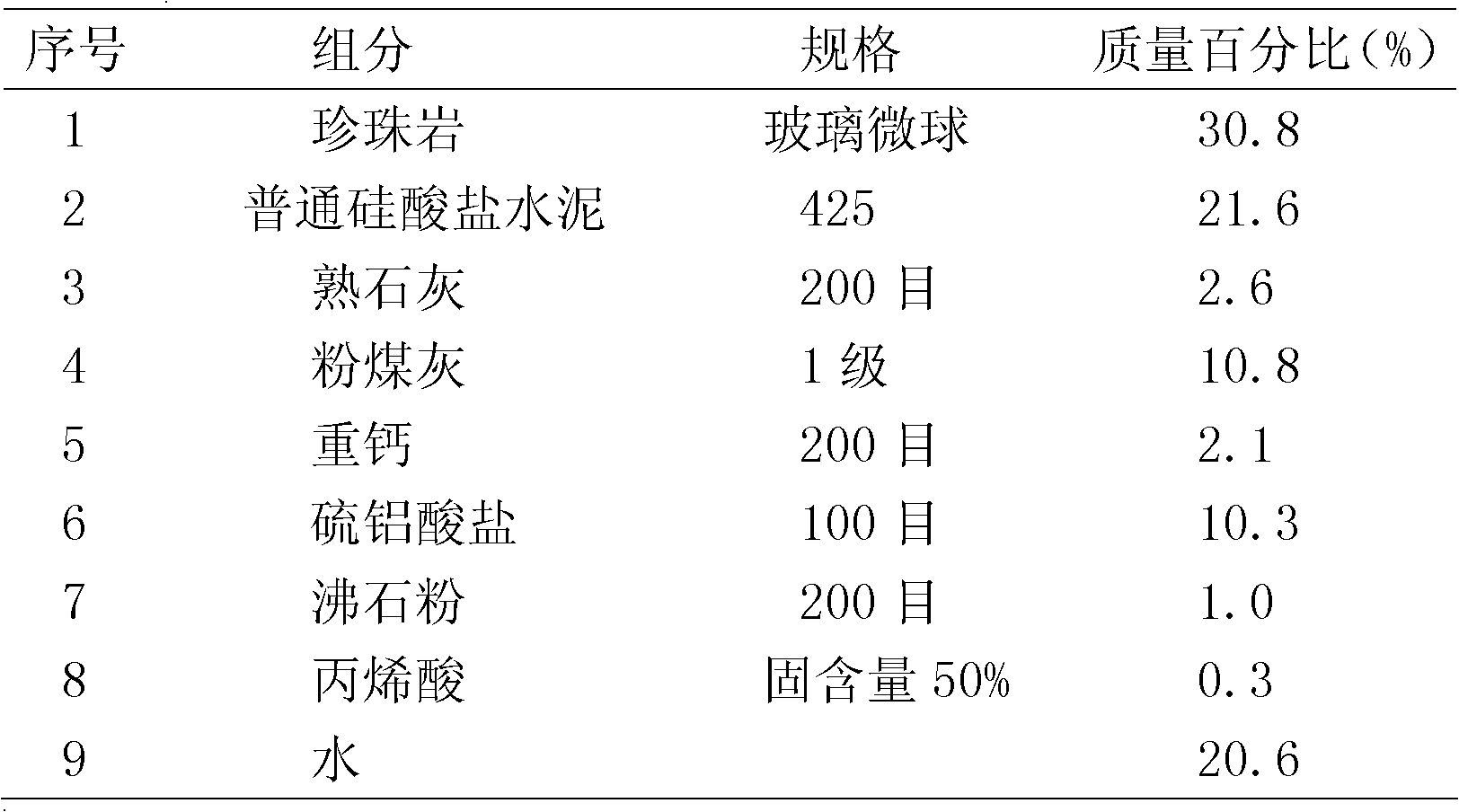

[0033] The integrally solidified inorganic thermal insulation board for building exterior walls designed by the present invention is mainly composed of raw materials such as perlite, modified cement, fly ash, fine sand, zeolite powder, slaked lime, and anti-seepage agent. After the above raw materials are dry mixed, wet mixed and injection molded in proportion, they are sent to the microwave coagulation accelerator for microwave irradiation. Under the action of microwave alternating electric field, the polar molecules or ions in the slurry are quickly oriented Movement and rearrangement also destroy the electrostatic balance of the slurry colloid, greatly increasing the crystallization reaction speed of the chemical substances in the slurry, which leads to the rapid solidification of the slurry; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com