Sample preparation method by fusing medium-carbon ferrochrome and high-carbon ferrochrome

A high-carbon ferrochromium and medium-carbon ferrochromium technology, which is applied in the field of alloy melting sample preparation, can solve the problems of damaging platinum crucibles and affecting the continued use of platinum crucibles, preventing corrosion, eliminating absorption and enhancement effects, and accurately analyzing data. reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

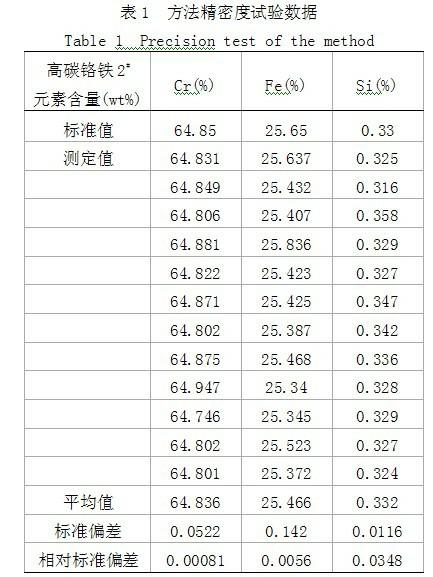

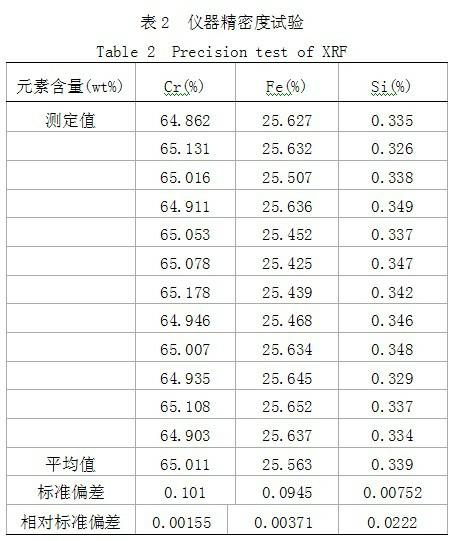

[0017] The melting sample preparation method comprises a. preparation of a flux crucible; b. preparation of an oxidizing agent and sample pre-oxidation treatment; c. preparation of a standard sample and a glass frit of the sample to be tested. Both high-carbon ferrochrome and medium-carbon ferrochrome alloys are difficult to dissolve in strong acids, but it is found through experiments that these two alloy samples are easily oxidized and decomposed by molten strong alkaline peroxides, and supplemented with appropriate oxidants can make the samples in the samples Elemental elements are fully oxidized. The flux used in the preparation of the flux crucible is anhydrous lithium tetraborate with a melting point of 917°C; the melting point of barium peroxide and potassium nitrate is 500°C and the boiling point is 800°C, and it decomposes and releases oxygen at the measured temperature, so the sample is pre-oxidized During the process, the flux crucible will not be melted and damaged...

Embodiment

[0020] Step a, preparation of flux crucible: Accurately weigh 6.0000g (±0.5mg) of analytically pure anhydrous lithium tetraborate dried in an electric blast drying oven at 105°C for 2h into a platinum crucible, and place the crucible containing lithium tetraborate Place it on the rotary support of an automatic electric heating melting furnace with a constant temperature of 1050°C, start the process of preparing a flux crucible for melting, the first standing time is 3 minutes, the furnace body swings and the rotating support spins for 10 minutes, and the final standing time is 2 minutes. After the melting is completed, take out the crucible and turn it slightly cold, and prepare the flux crucible according to the order of first hanging the crucible wall and then hanging the crucible bottom. Cool to room temperature and set aside.

[0021] Step b, preparation of oxidant and sample pre-oxidation treatment: the oxidant is prepared by mixing analytically pure barium peroxide and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com