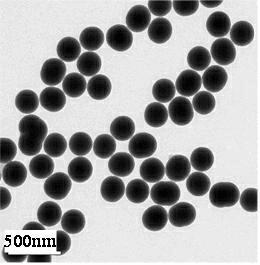

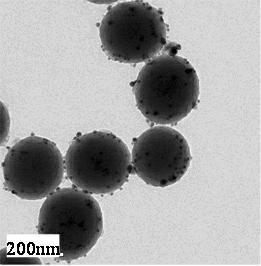

Method for preparing silicon dioxide-silver nanometer composite microspheres

A technology of silicon dioxide and composite microspheres, applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of poor thermal stability and low mechanical strength of polymers, and achieve high dispersion, small diameter of metal ions, and firm bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 640 g of absolute ethanol (chemically pure, the same below), 80 g of deionized water, 28 g (26% by weight, the same below) of ammonia water, stirred and mixed evenly at room temperature, and then added 40 g of ethyl orthosilicate (chemically pure, The same below), stirred and reacted at room temperature for 12 hours to obtain a milky white, uniform nano-silica solution. Add 4g of silane coupling agent γ-(methacryloyloxy)propyltrimethoxysilane (chemically pure, the same below) to the above-mentioned prepared nano-silica dispersion, and react continuously at room temperature for 24 hours, The obtained modified nano-silica dispersion liquid was centrifuged. Wash with ethanol for 3 times, and vacuum dry at 78° C. for 12 hours to obtain silica colloidal microspheres with double bonds on the surface. Ultrasonic dispersion of 2.5g surface-modified silica colloidal microspheres in 125g DMF (chemically pure, the same below) at room temperature, ultrasonic dispersion time 10-20 ...

Embodiment 2

[0020] 160g of absolute ethanol, 20g of deionized water, and 7ml of ammonia water were mixed evenly at room temperature, then 20g of ethyl orthosilicate was added, and stirred at room temperature for 24 hours to obtain a milky white, uniform nano-silica solution. 2 g of silane coupling agent vinyltrimethoxysilane was added to the above prepared nano-silica dispersion, and after continuous reaction at room temperature for 12 hours, the obtained modified nano-silica dispersion was centrifuged. Wash with ethanol three times, and vacuum dry at 78°C for 12 hours. 2.5 g of surface-modified silica colloidal microspheres were ultrasonically dispersed in 100 g of DMF, and the ultrasonic dispersion time was 10-20 minutes. Added 12.5 g of acrylic acid and 125 mg of initiator AIBN, and reacted for 10 hours under nitrogen protection. The product was separated by a high-speed centrifuge, washed three times with water, and dried in vacuum at 78°C for 12 hours to obtain a white powder that is...

Embodiment 3

[0022]160 g of absolute ethanol, 80 g of deionized water, and 28 g of ammonia water were mixed uniformly at room temperature, then 40 g of ethyl orthosilicate was added, and stirred at room temperature for 12 hours to obtain a milky white, uniform nano-silica solution. 4 g of coupling agent vinyltriethoxysilane was added to the prepared nano-silica dispersion, and after continuous reaction at room temperature for 24 hours, the obtained modified nano-silica dispersion was centrifuged. Wash with ethanol three times, and vacuum dry at 78°C for 12 hours. 2.5 g of surface-modified silica colloidal microspheres were ultrasonically dispersed in 25 g of DMF, and the ultrasonic dispersion time was 10-20 minutes. Added 25 g of acrylic acid and 25 mg of initiator AIBN, and reacted for 10 hours under nitrogen protection. The product was separated by a high-speed centrifuge, washed three times with water, and dried in vacuum at 78°C for 12 hours to obtain a white powder that is silica / poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com