Surface carboxyl-functionalized core-shell type magnetic composite microballoons and preparation method thereof

A technology of magnetic composite microspheres and carboxyl functionalization, which is applied in the field of functional materials to achieve the effects of controllable thickness and cross-linking degree, uniform particle size distribution and regular structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

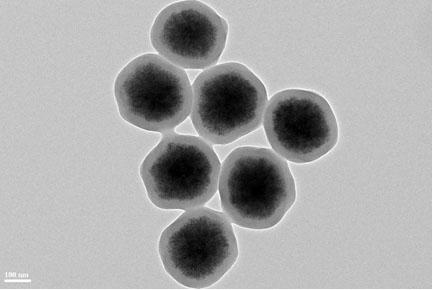

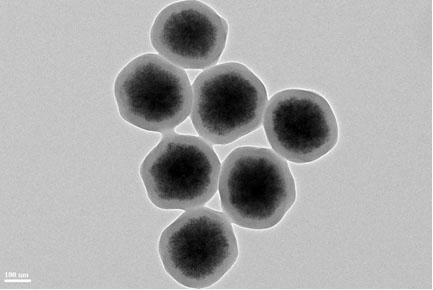

[0023] Example 1: Core-shell Fe with a shell thickness of about 30nm and a crosslinking degree of 20% 3 O 4 / PMAA microsphere preparation

[0024] 1. Preparation of citric acid stable magnetic cluster

[0025] Add 1.2g of ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 2.4g ammonium acetate (NH 4 Ac), 0.3g of citric acid is dissolved in 70ml of ethylene glycol, then added to a 150ml three-necked flask, and then heated to 120℃, after the reaction is kept for 1h, the liquid in the flask is transferred to a 100ml PTFE lining In the high-pressure reaction vessel, put the reaction vessel in an oven at 200°C for 24 hours and take it out, then cool it to room temperature with tap water. The product was separated by magnetic separation, washed with absolute ethanol to remove unreacted reactants, and finally the product was dispersed in absolute ethanol for later use.

[0026] 2. Modify the surface of the magnetic cluster with active vinyl

[0027] Add the magnetic cluster obtained above, 60ml ...

Embodiment 2

[0030] Example 2: Core-shell Fe with a shell thickness of about 60nm and a degree of crosslinking of 20% 3 O 4 / PMAA microsphere preparation

[0031] 1. The preparation of citric acid stabilized magnetic cluster is the same as that described in Example 1-1.

[0032] 2. The surface of the magnetic cluster is modified with active vinyl groups as described in Example 1-2.

[0033] 3. Core-shell Fe 3 O 4 / PMAA was prepared as described in Examples 1-3. The difference is methacrylic acid, N, N’ -The dosages of methylenebisacrylamide and 2,2-azobisisobutyronitrile are 2ml, 500mg and 40mg respectively.

Embodiment 3

[0034] Example 3: Core-shell Fe with a shell thickness of about 30nm and a crosslinking degree of 10% 3 O 4 / PMAA microsphere preparation

[0035] 1. The preparation of citric acid stabilized magnetic cluster is the same as that described in Example 1-1.

[0036] 2. The surface of the magnetic cluster is modified with active vinyl groups as described in Example 1-2.

[0037] 3. Core-shell Fe 3 O 4 / PMAA was prepared as described in Examples 1-3. The difference is N, N’ -The dosage of methylene bisacrylamide is 110 mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com