Rubber valve body composite material and preparation method thereof

A composite material and rubber valve technology, which is applied in the field of rubber material processing, can solve problems such as the limitation of mechanical properties of materials, and achieve the effects of improving service life, light weight, and excellent high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

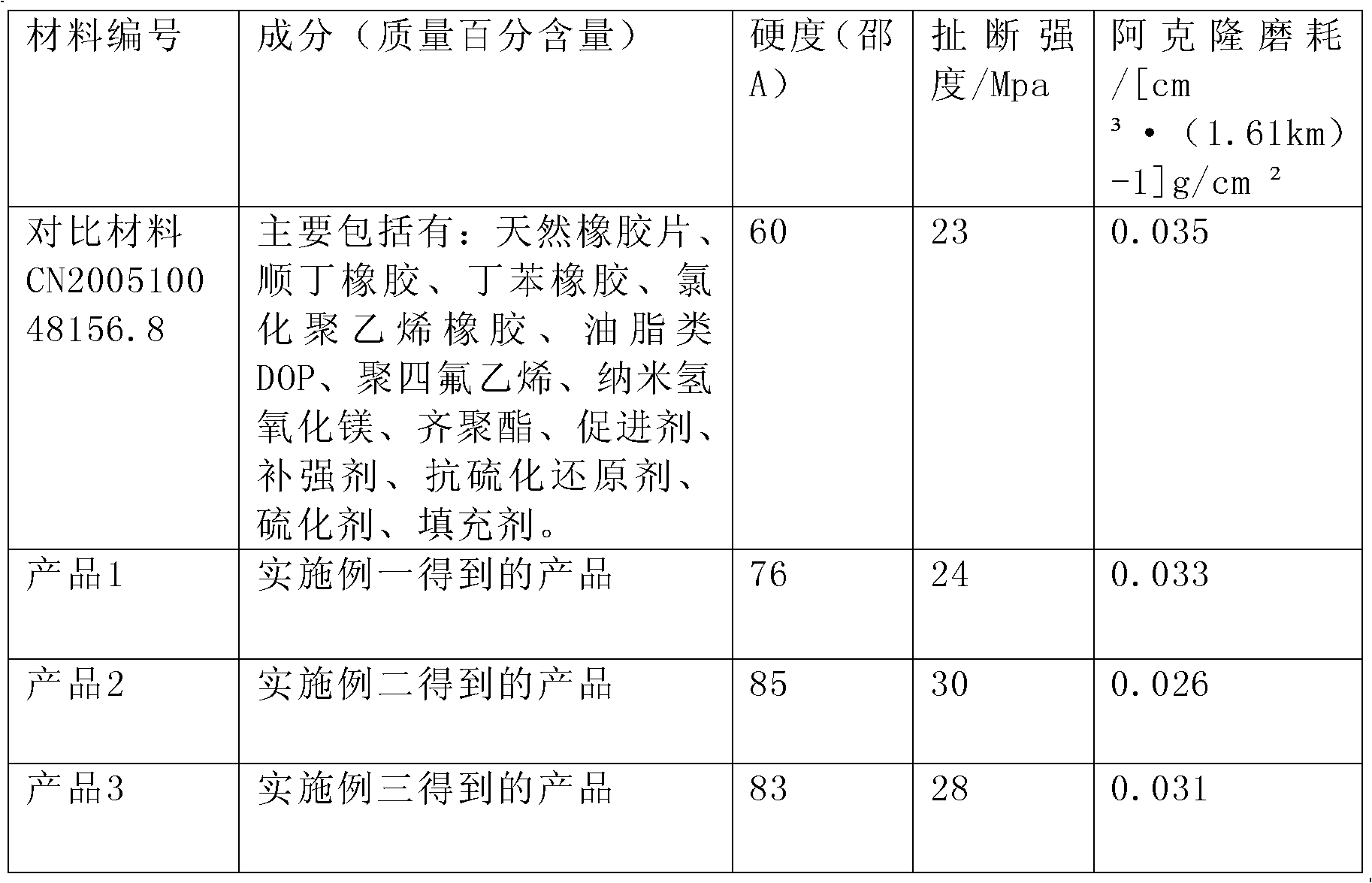

Examples

Embodiment 1

[0038] 1. Raw material preparation:

[0039] Weigh 60 parts of fluororubber, 30 parts of styrene-butadiene rubber, 10 parts of nitrile rubber, 3 parts of magnesium hydroxide, 1 part of microcrystalline wax, 3 parts of oligopolyester, 2 parts of quinone, 1 part of titanium dioxide, accelerator 1 part of N-cyclohexyl-2-benzothiazole sulfenamide C13H16N2S2, 1 part of anti-aging agent N-phenyl-N'-yl-p-phenylenediamine.

[0040] 2. The preparation process is as follows:

[0041] (1) Mixing: Start the open mill, put fluorine rubber, styrene-butadiene rubber and nitrile rubber into the open mill, and turn over until the three kinds of rubber are fused, then add magnesium hydroxide and microcrystalline wax, oligoester, Titanium dioxide, hydroquinone, anti-aging agent N-phenyl-N-yl-p-phenylenediamine, refining 6-8 times, and then adding accelerator N-cyclohexyl-2-benzothiazole sulfenamide C13H16N2S2 and fully Turning, the number of times of thinning is 11 times, and the temperature o...

Embodiment 2

[0045] 1. Raw material preparation:

[0046] Weigh 70 parts of fluorine rubber, 40 parts of styrene-butadiene rubber, 15 parts of nitrile rubber, 5 parts of magnesium hydroxide, 2 parts of microcrystalline wax, 5 parts of oligopolyester, 3 parts of quinone, 2 parts of titanium dioxide, accelerator N-cyclohexyl-2-benzothiazole sulfenamide C13H16N2S22 parts, anti-aging agent N-phenyl-N'-yl-p-phenylenediamine 2 parts.

[0047] 2. The preparation process is as follows:

[0048] (1) Mixing: Start the open mill, put fluorine rubber, styrene-butadiene rubber and nitrile rubber into the open mill, and turn over until the three kinds of rubber are fused, then add magnesium hydroxide and microcrystalline wax, oligoester, Titanium dioxide, hydroquinone, anti-aging agent N-phenyl-N-yl-p-phenylenediamine, refining 6-8 times, and then adding accelerator N-cyclohexyl-2-benzothiazole sulfenamide C13H16N2S2 and fully Turning, the number of times of thinning is 15 times, and the temperature o...

Embodiment 3

[0052] 1. Raw material preparation:

[0053] Weigh 65 parts of fluororubber, 35 parts of styrene-butadiene rubber, 12 parts of nitrile rubber, 4 parts of magnesium hydroxide, 1.5 parts of microcrystalline wax, 4 parts of oligopolyester, 2.5 parts of quinone, 1.5 parts of titanium dioxide, accelerator N-cyclohexyl-2-benzothiazole sulfenamide C13H16N2S21.5 parts, anti-aging agent N-phenyl-N'-yl-p-phenylenediamine 1.5 parts.

[0054] 2. The preparation process is as follows:

[0055] (1) Mixing: Start the open mill, put fluorine rubber, styrene-butadiene rubber and nitrile rubber into the open mill, and turn over until the three kinds of rubber are fused, then add magnesium hydroxide and microcrystalline wax, oligoester, Titanium dioxide, hydroquinone, anti-aging agent N-phenyl-N-yl-p-phenylenediamine, refining 6-8 times, and then adding accelerator N-cyclohexyl-2-benzothiazole sulfenamide C13H16N2S2 and fully Turning, the number of times of thinning is 13 times, and the temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com