Catalyst component, catalyst and method for olefin polymerization

An olefin polymerization and catalyst technology, applied in the field of olefin polymerization catalyst components, can solve the problems of narrow molecular weight distribution and high preparation cost of olefin polymers, and achieve the effects of high stereoselectivity, wide molecular weight distribution, and good hydrogen modulation sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

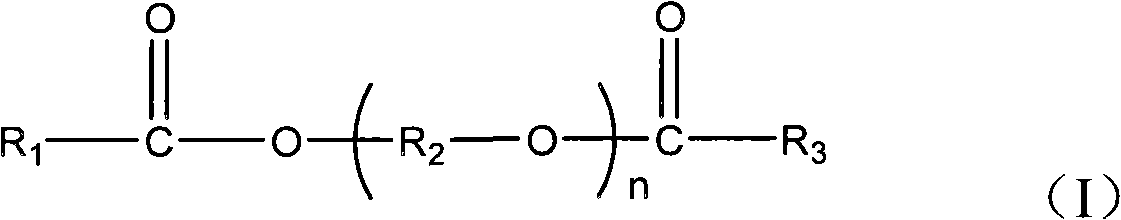

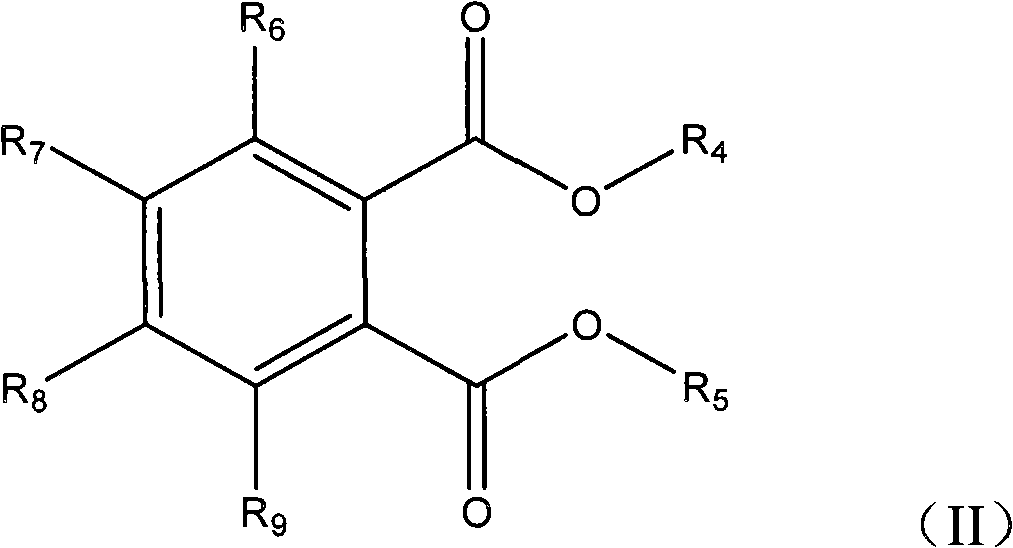

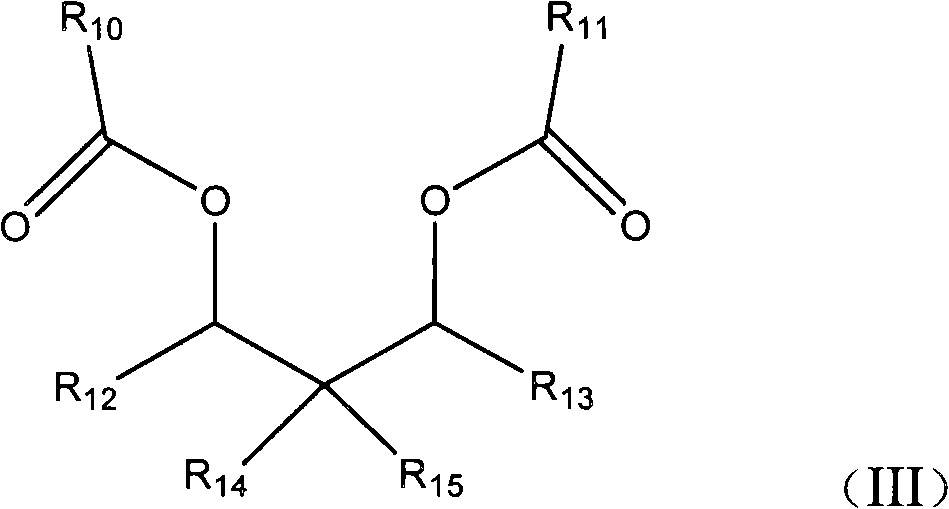

[0071] In the preparation of the above-mentioned olefin polymerization catalyst component, the molar ratio of the amount of the internal electron donor a to the magnesium atom can generally be 0.01-1, preferably 0.05-0.5. The molar ratio of the amount of the internal electron donor b to the magnesium atom can generally be 0.01-1, preferably 0.05-0.5.

[0072] According to the olefin polymerization catalyst of the present invention, the catalyst is used for 2 = The polymerization of olefins represented by CHR, wherein R is hydrogen or an alkyl group with 1 to 6 carbon atoms, said catalysts include the reaction products of the following substances:

[0073] (1) the above-mentioned olefin polymerization catalyst component;

[0074] (2) organoaluminum compounds as cocatalysts;

[0075] (3) Optionally, an external electron donor compound.

[0076] In the above olefin polymerization catalyst, the organoaluminum compound may be various organoaluminum compounds commonly used in the...

preparation example 1

[0094] Preparation of Triethylene Glycol Dibenzoate

[0095] Take 0.2mol (30g) of triethylene glycol and dissolve it in a mixture of 100mL of dry tetrahydrofuran and 100mL of pyridine, and stir evenly; while stirring, add 0.5mol (70g) of benzoyl chloride; continue stirring for 1 hour, then raise the temperature of the system to reflux, and reflux React for 6 hours; add 50 mL of water and stir to reflux for 2 hours. Add 200 mL of anhydrous diethyl ether, separate the layers, wash the organic phase with 1N hydrochloric acid until pH = 4, then wash with saturated saline solution until neutral, remove the solvent by distillation under normal pressure, and recrystallize from n-hexane to obtain 63 g of white solid. 1 H-NMR (TMS, CDCl 3 , ppm): δ8.38(d, 4H), 7.55(t, 2H), 7.42(t, 4H), 4.47(t, 4H), 3,84(t, 4H), 3,72(s, 4H ).

preparation example 2

[0097] Magnesium diethoxide preparation

[0098] In a 1L reactor equipped with a stirrer, a reflux condenser, a thermometer and a burette, after sufficient replacement with nitrogen, 550 mL of ethanol was added to the reactor, and 0.68 g of iodine was dissolved. After stirring, the temperature was raised until reaching the reflux temperature of the reaction system. Then add magnesium powder 32g successively. React until no more hydrogen is released. Then wash, separate and dry to obtain a bulk density of 0.25g / cm 3 , Diethoxymagnesium with an average particle size (D50) of 38.0 μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com