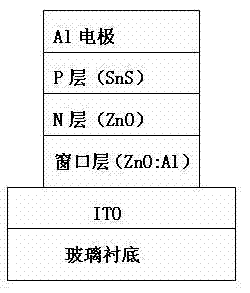

Preparation method of ZnO/SnS solar cell element containing ZnO:Al window layer

A technology of solar cells and window layers, applied in electrical components, coatings, circuits, etc., can solve problems such as unstable performance, and achieve the effects of good crystal quality, dense film, and high nucleation density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

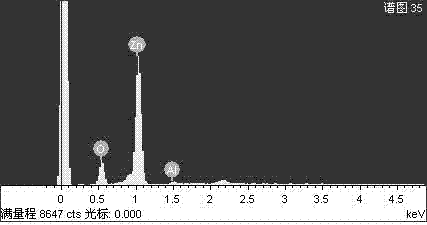

Examples

Embodiment

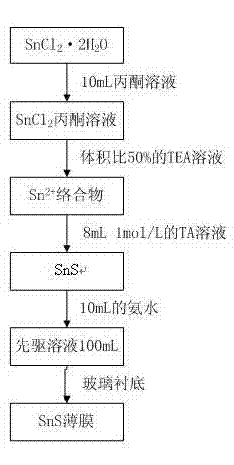

[0021] Embodiment: In this embodiment, the following processes and steps are included:

[0022] 1. Cleaning of the glass substrate coated with ITO film: Soak the glass substrate substrate in a beaker filled with an appropriate amount of acetone, and put it into an ultrasonic generator for ultrasonic treatment for about 15 minutes. Pour out the acetone, add an appropriate amount of alcohol, and continue to sonicate in the ultrasonic generator for 15 minutes. Pour out the alcohol, add an appropriate amount of distilled water, and put it into an ultrasonic generator for cleaning, usually for 15 minutes. The purpose is to remove the alcohol on the glass surface. Put the cleaned glass substrate into an electric heating constant temperature blast drying oven and dry it for use.

[0023] 2. Use RF magnetron sputtering device to sputter ZnO:Al target material: ZnO:Al raw material is obtained from outsourcing; JC500-3 / D magnetron sputtering coating machine is used, which consists of h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice constant | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com