Composite elastic terrace

An elastic and composite technology, used in coatings, buildings, roads, etc., can solve problems such as cracking, blistering, shelling, etc., achieve good bonding performance, reduce product costs, and improve elongation at break. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

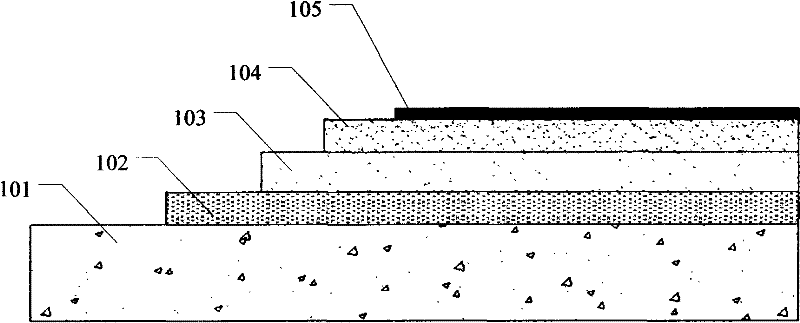

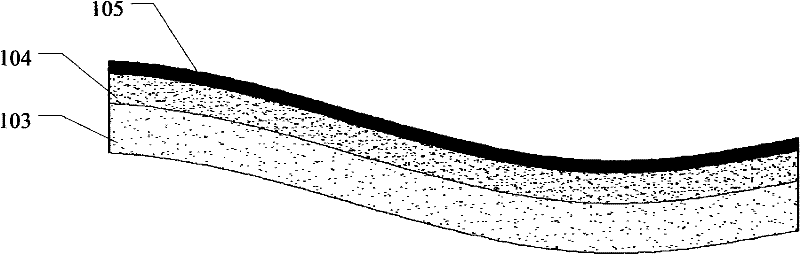

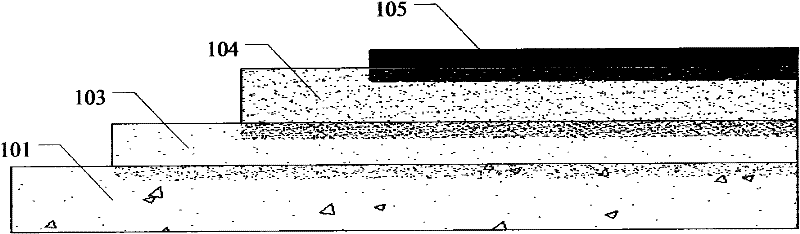

Image

Examples

Embodiment 1

[0065] The acrylic polymer emulsion (here adopts the American Rohm and Hass produced AC-261 acrylic emulsion polymer, its solid content is 49.5%~50.5%) mixed with water, while stirring, add rubber powder, rubber powder:polymer emulsion:water=8:1:2.5 (mass ratio). According to the mass ratio, the rubber powder consists of 50 parts of ordinary Portland cement 425R, 20 parts of quartz sand, 0.2 parts of water reducer (Melment F10 produced by Degussa, Germany) and 0.2 part of defoamer (using Dehydran 1922 produced by Corning Company) is pre-mixed. After stirring evenly, make up points and level the base surface, and use a ruler to control the flatness, so that the height error within 2m is not greater than 3mm to become a leveling layer. The compressive strength of the leveling layer 28d is greater than 32MPa, the flexural strength is greater than 9MPa, and the bonding strength is 1.8Mpa.

Embodiment 2

[0067] The acrylic polymer emulsion (here adopts the American Rohm and Hass produced AC-261 acrylic acid emulsion polymer, its solid content is 49.5%~50.5%) mixed with water, while stirring, add rubber powder, rubber powder:polymer emulsion:water=4:1:1 (mass ratio). According to the mass ratio, the rubber powder consists of 50 parts of ordinary Portland cement 425R, 20 parts of coarse rubber particles with a particle size of 1-3 mm, 0.2 parts of water reducer (Melment F10 produced by Degussa, Germany) and 0.2 parts of dispersant. The foaming agent (Dehydran 1922 produced by Corning Company) was pre-mixed. Scrape the mixed slurry with a batch knife for construction, and there should be no obvious batch marks on the surface. The thickness is about 2mm. After 24 hours, polish the surface of the elastic layer until there is no obvious unevenness. Continue to maintain for 2 days until the rubber particles cannot be removed by hand. The Shore hardness (Shore A) of the elastic l...

Embodiment 3

[0069] The acrylic polymer emulsion (here adopts the American Rohm and Hass produced AC-261 acrylic acid emulsion polymer, its solid content is 49.5%~50.5%) mixed with water, while stirring, add rubber powder, rubber powder:polymer emulsion:water=4:1:1 (mass ratio). According to the mass ratio, the rubber powder consists of 50 parts of ordinary Portland cement 425R, 20 parts of fine rubber particles with a particle size of 0.1-0.5 mm, 0.2 parts of water reducer (Melment F10 produced by Degussa, Germany) and 0.2 parts The defoamer (Dehydran 1922 produced by Corning Company) was pre-mixed. Scrape the mixed slurry with a trowel, and there should be no obvious batch marks on the surface. Batch scraping about 1-2mm. After 24 hours, polish the surface of the elastic layer of fine rubber particles until it feels smooth without roughness. The thickness of the elastic layer was 1 mm. Preserve for 2 days until the rubber particles cannot be picked out by hand. The Shore hardness (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com