Polymeric thermoplastic compositions having excellent resistance to moisture and oxygen transmission and sheet which are made of these polymeric thermoplastic compositions

A resin composition and sheet technology, which can be used in synthetic resin layered products, household appliances, transportation and packaging, etc., can solve the problems of oxygen and moisture barrier properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0086] [Preparation Example 1] 3-Methyl-5-[{BF 4 - Bu 3 N + (CH 2 ) 3} 2 Synthesis of CH}]-salicylaldehyde

[0087] The title compound was prepared by hydrolysis of the ligand represented by the structure below. This compound is synthesized according to known methods. (Angew. Chem. Int. Ed., 2008, 47, 7306-7309)

[0088] [Structural formula 1]

[0089]

[0090] The compound of structural formula 1 was dissolved in 4 mL of dichloromethane, after dissolution, 2N2, 5 mL of HI aqueous solution was added, and stirred at 70° C. for 3 hours. The aqueous layer was removed, and the dichloromethane layer was washed with water. The dichloromethane layer was then dried with anhydrous magnesium chloride, and the solvent was removed under reduced pressure. Purification by silica gel column chromatography of a mixed solution of dichloromethane / ethanol 10:1 afforded 3-methyl-5-[{BF 4 - Bu 3 N + (CH 2 ) 3} 2 CH}]-salicylaldehyde 0.462g. (Yield: 95%). Dissolve the compoun...

preparation example 2

[0092] [Preparation Example 2] Synthesis of Complex 1

[0093] Complex 1 represented by the following general formula 13 is 3-methyl-5-[{BF prepared in Preparation Example 1 4 - Bu 3 N + (CH 2 ) 3} 2 CH}]-salicylaldehyde compound was synthesized.

[0094] [Formula 13]

[0095]

[0096] Weigh ethylenediamine dihydrochloride 10mg (0.074mmol), sodium tert-butoxide 14mg and 3-methyl-5-[{BF prepared in Preparation Example 1 4 - Bu 3 N + (CH 2 ) 3} 2 CH}]-salicylaldehyde compound 115 mg, and placed in a vial in a dry box, then added 2 mL of ethanol in the vial. The vial was stirred overnight at room temperature. The reaction mixture was filtered and ethanol was removed from the filtrate under pressure. After removal of ethanol, the filtrate was redissolved in dichloromethane and filtered once more. After removing the solvent under pressure, Co(OAc) was added 213mg (0.074mmol) and ethanol 2mL. The reaction mixture was stirred at room temperature for 3 hours, the...

preparation example 3

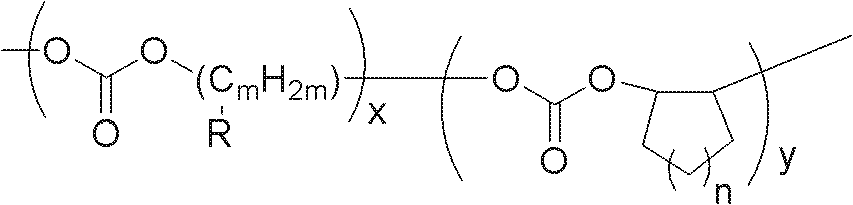

[0097] [Preparation Example 3] Synthesis of Copolymer (PPC) Using Carbon Dioxide / Propylene Oxide

[0098] 1162 g (20.0 mol) of propylene oxide dissolved with 0.454 g of the complex (calculated based on the monomer / catalyst ratio) was injected into a 3L autoclave through a tube. The complex is complex 1 prepared in Preparation Example 2. Carbon dioxide was injected into the reactor with a pressure of 17 bar, while the temperature of the reactor was raised by using a circulating water bath preset at 80° C., and stirring was started. After 30 minutes, measure and record the time point at which the pressure of carbon dioxide starts to drop. After 2 hours from this time point, the reaction was stopped by removing carbon dioxide gas. Further, 830 g of propylene oxide was added to the obtained viscous solution to reduce the viscosity of the solution, and flowed through a pad of silica gel [50 g, produced by MERK Company, particle size 0.040-0.063 mm (230-400 mesh)] to obtain a colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com