Membrane-less electrodeionization-based water softening device and water softening method therefor

A hard water softening and electrodeionization technology, which is applied in separation methods, ion exchange water/sewage treatment, general water supply saving, etc., can solve the problem that the amount of treated water cannot be infinitely enlarged, so as to improve resource utilization, reduce energy consumption, and flow The effect of widening the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

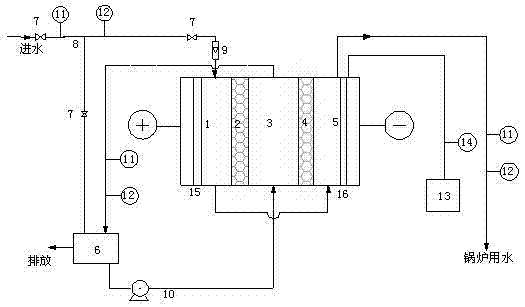

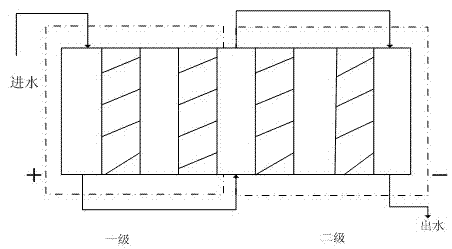

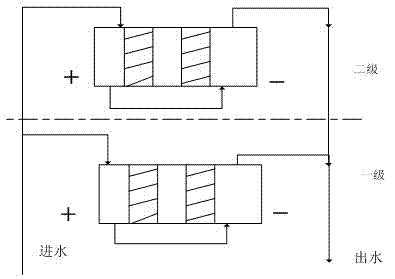

[0029] use figure 1 Shown is a membraneless electrodeionization hard water softening device. The anode is a titanium ruthenium-plated mesh electrode, and the cathode is a stainless steel mesh electrode; the anion and cation exchange resins are D201 macroporous strong basic styrene-based hydrogen-oxygen resin and D001 macroporous styrene-based hydrogen-type resin; the size of the pool 0.05432m 3 (1.94*0.2*0.14), the thickness of the resin wall is 0.07m. The NaCl content in the raw water is about 10mg / L. First, the raw water is diverted by the three-way valve, and the main line enters the first fresh water tank, and then flows out through the second fresh water tank. The auxiliary line water enters the concentrated water tank; before the power is turned on, the conductivity of the effluent water is close to the conductivity of the raw water; then 30V voltage is applied to both sides of the device to perform electrodeionization treatment on the raw water; after 48 hours of cont...

Embodiment 2

[0031] In Example 2, a membraneless electrodeionization hard water softening device is used to soften boiler water. The deionization device, principle, and operation steps in Example 2 are the same as in Example 1; the raw water is tap water, and the total hardness is 232mg / L (calculated as calcium carbonate); 30V is applied to both ends of the electrodes of the device, and after a week of stable and continuous operation , the total hardness of the effluent is less than 2mg / L (calculated as calcium carbonate), according to the provisions of the national standard GB / T 1576-2008, natural circulation steam boilers, using water outside the boiler, the hardness should be ≤ 3mg / L (calculated as calcium carbonate ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com