Preparation method of photosensitive conductive polyaniline nanoparticles

A conductive polyaniline and nanoparticle technology, which is applied in the field of preparation of photosensitive conductive polyaniline nanoparticles, can solve the problems of being unsuitable for mass production, demanding conditions, and high cost, and achieve improved processing performance and environmental friendliness , expand application, good film-forming performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

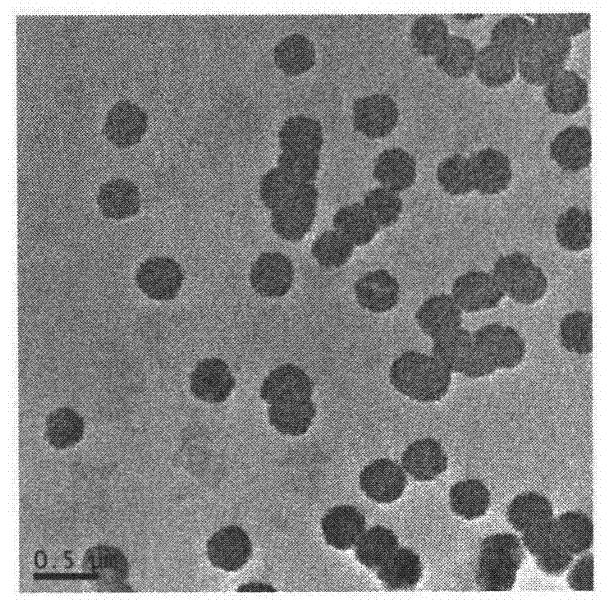

Image

Examples

Embodiment 1

[0016] Weigh 2.45g of 2-acrylamide-2-methylpropanesulfonic acid, 0.62g of ethyl coumarin, 0.072g of initiator azobisisobutyronitrile in 25mL of dioxane, fill with nitrogen for 30 minutes, 65°C The reaction was carried out for 24 hours, cooled to room temperature, the excess solvent was evaporated, and the pure copolymer was obtained by precipitation in dichloroethane. The copolymer was dissolved in an aqueous solution, cooled to 0° C., a hydrochloric acid solution of aniline (0.5 g) was added, and an aqueous solution containing 1.3 g of ammonium persulfate was added in one batch, and stirred for 8 hours. The obtained dark green polyaniline dispersion liquid was subjected to centrifugation (10000 rpm) to separate and purify to obtain photosensitive conductive polyaniline nanoparticles.

Embodiment 2

[0018] Weigh 1.72g of acrylic acid, 0.85g of 2-cinnamic acid acyloxyethyl-(meth)acrylate, 0.065g of initiator azobisisobutyronitrile in 25mL of dioxane, fill with nitrogen for 30 minutes, at 65°C React for 24 hours, cool to room temperature, evaporate excess solvent, and precipitate in dichloroethane to obtain pure copolymer. The copolymer was dissolved in an aqueous solution, cooled to 0° C., a hydrochloric acid solution of aniline (0.78 g) was added, and an aqueous solution containing 1.9 g of ammonium persulfate was added in one batch, and stirred for 8 hours. The obtained dark green polyaniline dispersion was subjected to centrifugation (8000 rpm) for separation and purification to obtain photosensitive conductive polyaniline nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com