Preparation method for high-strength high-toughness flame-retardant polyamide

A technology of flame-retardant polyamide and high toughness, which is applied in the field of preparation of flame-retardant polyamide, which can solve the problems of affecting the surface finish of products, affecting the mechanical properties of substrates, and improving product density, so as to improve production capacity and product appearance quality and Smoothness, improve processing fluidity, slow down the effect of heat aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

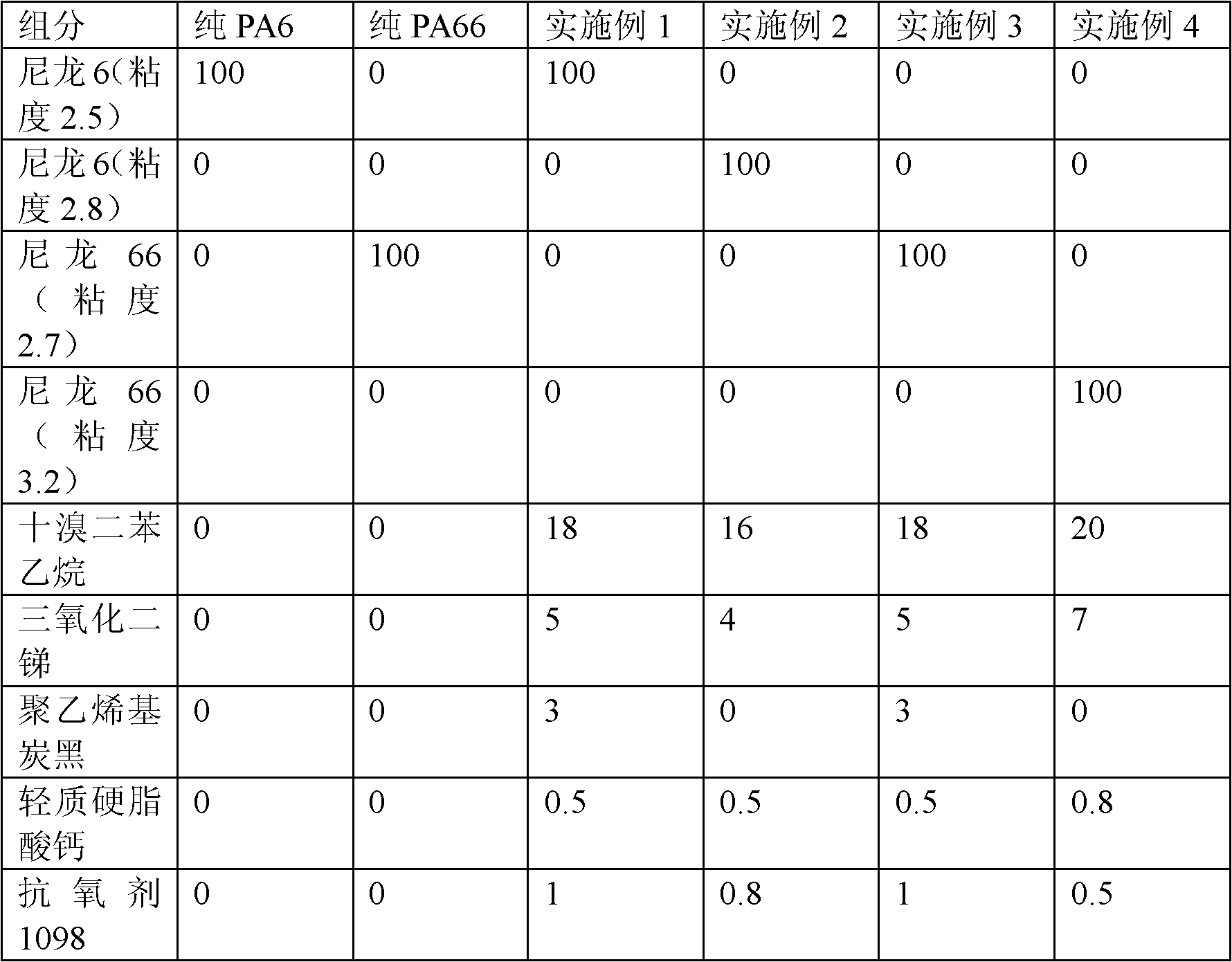

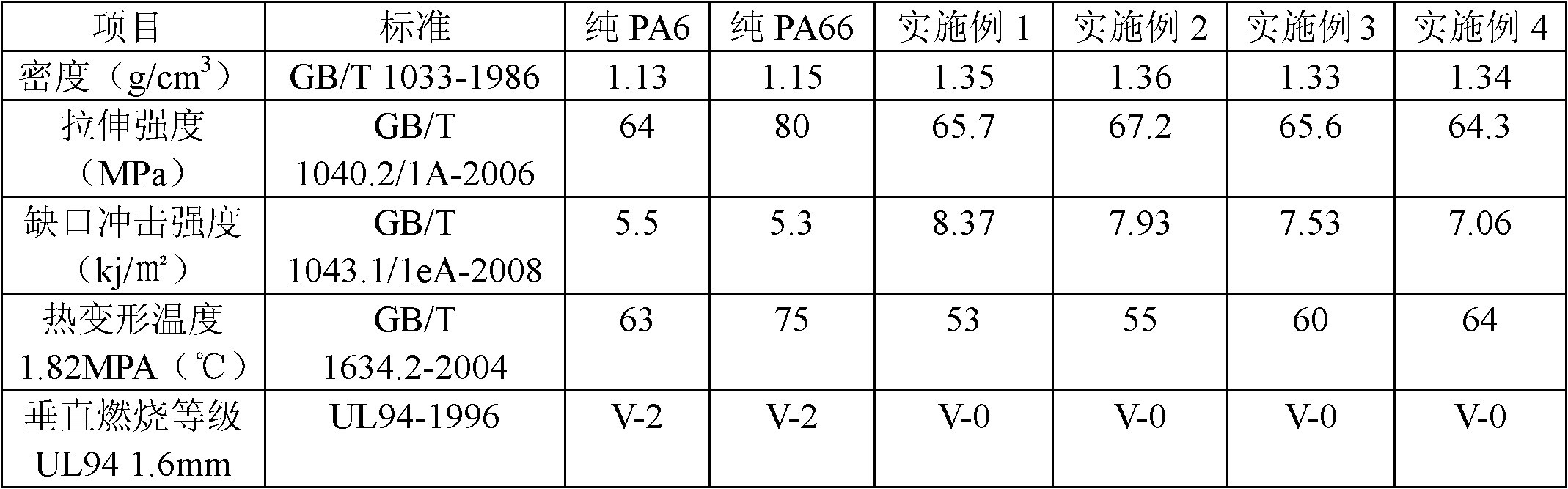

Embodiment 1

[0020] In terms of parts by mass, 100 parts of nylon 6 with a viscosity of 2.5 was dried with a vacuum rotary drier and mixed with 18 parts of decabromodiphenylethane, 5 parts of antimony trioxide, 3 parts of polyvinyl carbon black, 0.5 parts of light Calcium stearate and 1 part of antioxidant 1098 are mixed evenly and added to the twin-screw extruder from the feeder. The temperature is 240°C, the temperature in the fourth zone is 235°C, the temperature in the fifth zone is 230°C, the temperature in the sixth zone is 230°C, the temperature in the seventh zone is 235°C, the temperature in the eighth zone is 240°C, the temperature of the head is 240°C, and the speed of the main engine is 240r / min. Extrude, cool, dry, and pelletize through the head of the machine to obtain a flame-retardant polyamide composition product. The prepared composite product is injection-molded into a standard sample bar for testing according to a standard size, and the physical properties are tested ac...

Embodiment 2

[0022] In terms of parts by mass, 100 parts of nylon 6 with a viscosity of 2.8 was dried with a vacuum rotary drier and mixed with 16 parts of decabromodiphenylethane, 4 parts of antimony trioxide, 0.5 parts of light calcium stearate, 0.8 parts of antimony Oxygen 1098 is mixed evenly and fed into the twin-screw extruder from the feeder. The temperature of the first zone of the extruder from the feeding port to the die head is 220°C, the temperature of the second zone is 260°C, the temperature of the third zone is 250°C, and the temperature of the fourth zone is 240°C ℃, the temperature in the fifth zone is 235°C, the temperature in the sixth zone is 235°C, the temperature in the seventh zone is 240°C, the temperature in the eighth zone is 245°C, the temperature of the head is 245°C, the speed of the main engine is 240r / min, extrusion from the head of the extruder, cooling, Dried and pelletized to obtain a flame-retardant polyamide composition product. The prepared composite pr...

Embodiment 3

[0024] In terms of parts by mass, 100 parts of nylon 66 with a viscosity of 2.7 was dried with a vacuum rotary drier and mixed with 18 parts of decabromodiphenylethane, 5 parts of antimony trioxide, 3 parts of polyvinyl carbon black, 0.5 parts of light Calcium stearate and 1 part of antioxidant 1098 are mixed evenly and added to the twin-screw extruder from the feeder. The temperature is 260°C, the temperature in the fourth zone is 250°C, the temperature in the fifth zone is 240°C, the temperature in the sixth zone is 240°C, the temperature in the seventh zone is 245°C, the temperature in the eighth zone is 250°C, the temperature of the head is 255°C, and the speed of the main engine is 300r / min. Extrude, cool, dry, and pelletize through the head of the machine to obtain a flame-retardant polyamide composition product. The prepared composite product is injection-molded into a standard sample bar for testing according to a standard size, and the physical properties are tested a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com