Fungus spore germination carrying membrane and production method thereof

A technology of spore germination and production method, which is applied in the field of fungal spore germination carrier film and its preparation, and can solve problems such as inconvenient use, troublesome management, and debris entering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

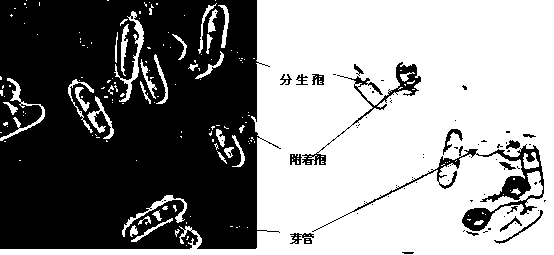

Image

Examples

Embodiment 1

[0019] Weigh 7.0 g of potassium dihydrogen phosphate (accurate to 0.01 g) and 9.0 g of dipotassium hydrogen phosphate (accurate to 0.01 g) into a 500 mL beaker, add about 200 mL of deionized water and stir until completely dissolved; take deionized water Heat about 800 mL in a heatable container, weigh 12 g of agar (accurate to 0.1 g), pour it into hot water, and continue heating until the agar is completely dissolved; the melted agar solution is filtered with 4 layers of gauze to remove insoluble matter; Add the above-prepared inorganic salt solution to the filtrate, add 2.0 g (accurate to 0.1 g) Tween-20 and stir evenly, dilute to 1000 mL with 85°C hot water, and stir evenly; add agar solution (10 mL ~12 mL, the liquid temperature of the composition is about 60°C) and slowly pour it on a clean glass plate that has been preheated to about 60°C (60°C constant temperature water bath for about 5 minutes), spread it out, and level it into a thickness of about 1.0 mm and an area of...

Embodiment 2

[0021] Agar 10 g

[0022] Sodium dihydrogen phosphate monohydrate (NaH 2 PO 4 ·H 2 O) 17g

[0023] Disodium hydrogen phosphate dihydrate (NaH 2 PO 4 2H 2 O) 14g

[0024] Tween-20 1.5 g

[0025] Dilute to 1000mL with deionized water.

[0026] The preparation method is the same as in Example 1. The broken rate of the finished dry film is less than 2%, and the broken rate during use is less than 4%.

Embodiment 3

[0028] Agar 18 g

[0029] Potassium dihydrogen phosphate .3.5 g

[0030] Dipotassium hydrogen phosphate 4.5g

[0031] Sodium dihydrogen phosphate monohydrate (NaH 2 PO 4 ·H 2 O) 8.5g

[0032] Disodium hydrogen phosphate dihydrate (NaH 2 PO 4 2H 2 O) 7g

[0033] Tween-20 4 g

[0034] Dilute to 1000mL with deionized water.

[0035] The preparation method is the same as in Example 1. The broken rate of the finished dry film is less than 1%, and the broken rate during use is less than 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crush indicators | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

| crush indicators | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com