Optical ion sensing film for detecting metal ions, and preparation method and application thereof

A technology of metal ions and sensing membranes, applied in the field of chemical detection, can solve problems such as inability to achieve continuous and repeated detection, and achieve high quantum yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

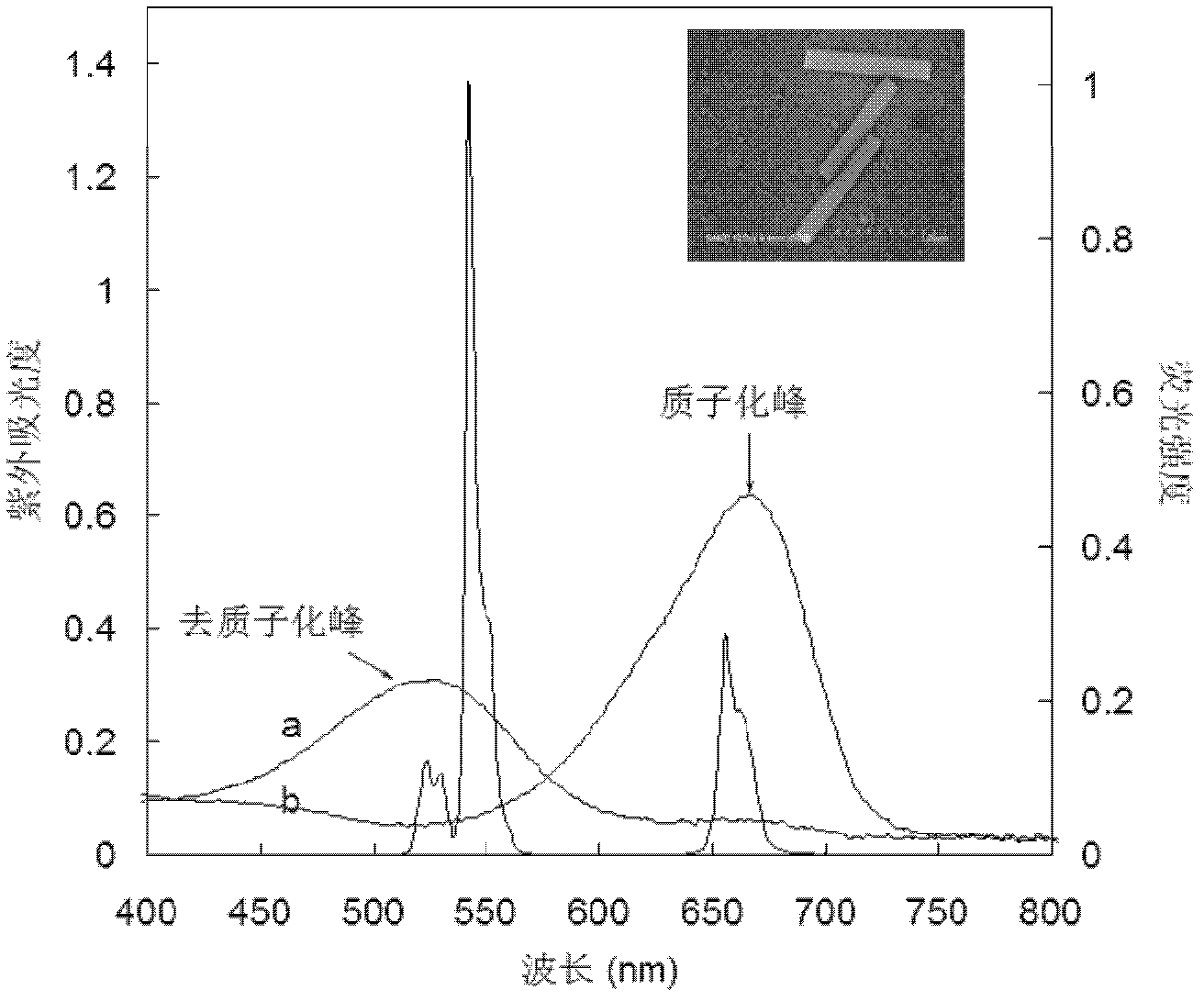

[0039] Example 1: NaYF 4 : Synthesis of Er, Yb nanorods.

[0040] NaYF 4 :Er,Yb nanorods were synthesized according to the literature 18 .

[0041] The specific steps are as follows: sodium hydroxide (1.2 g, 30 mmol), water (7 mL), ethanol (12 mL) and oleic acid (22 mL) are mixed together and stirred to form a clear solution. Add a total of 1 mmol of rare earth chloride (total 2 mL, 0.5 M, the doping ratio of rare earth ions according to the molar ratio: 78 mol% Y+20 mol% Yb+2 mol% Er) aqueous solution under constant magnetic stirring, and stir evenly. 5 mL of 1 M sodium fluoride solution was added dropwise. The mixed solutions were stirred for about 10 min, transferred to a 50 mL hydrothermal reactor, packaged, and hydrothermally treated at 195 °C for 16 h. After natural cooling, the samples were dissolved and collected with cyclohexane, ethanol was added to precipitate the samples, centrifuged, washed several times with ethanol and water, and then vacuum-dried.

[0042...

Embodiment 2

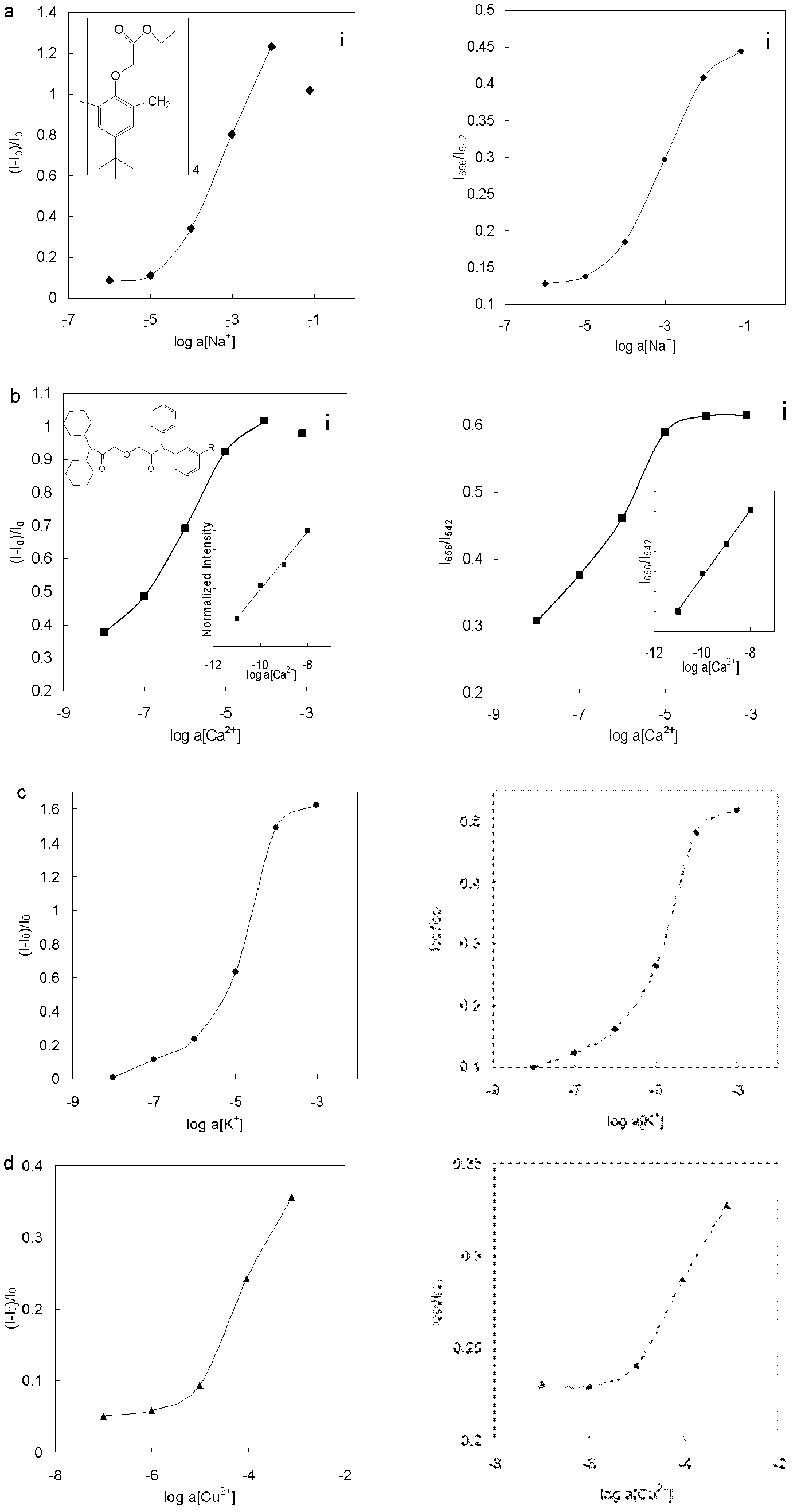

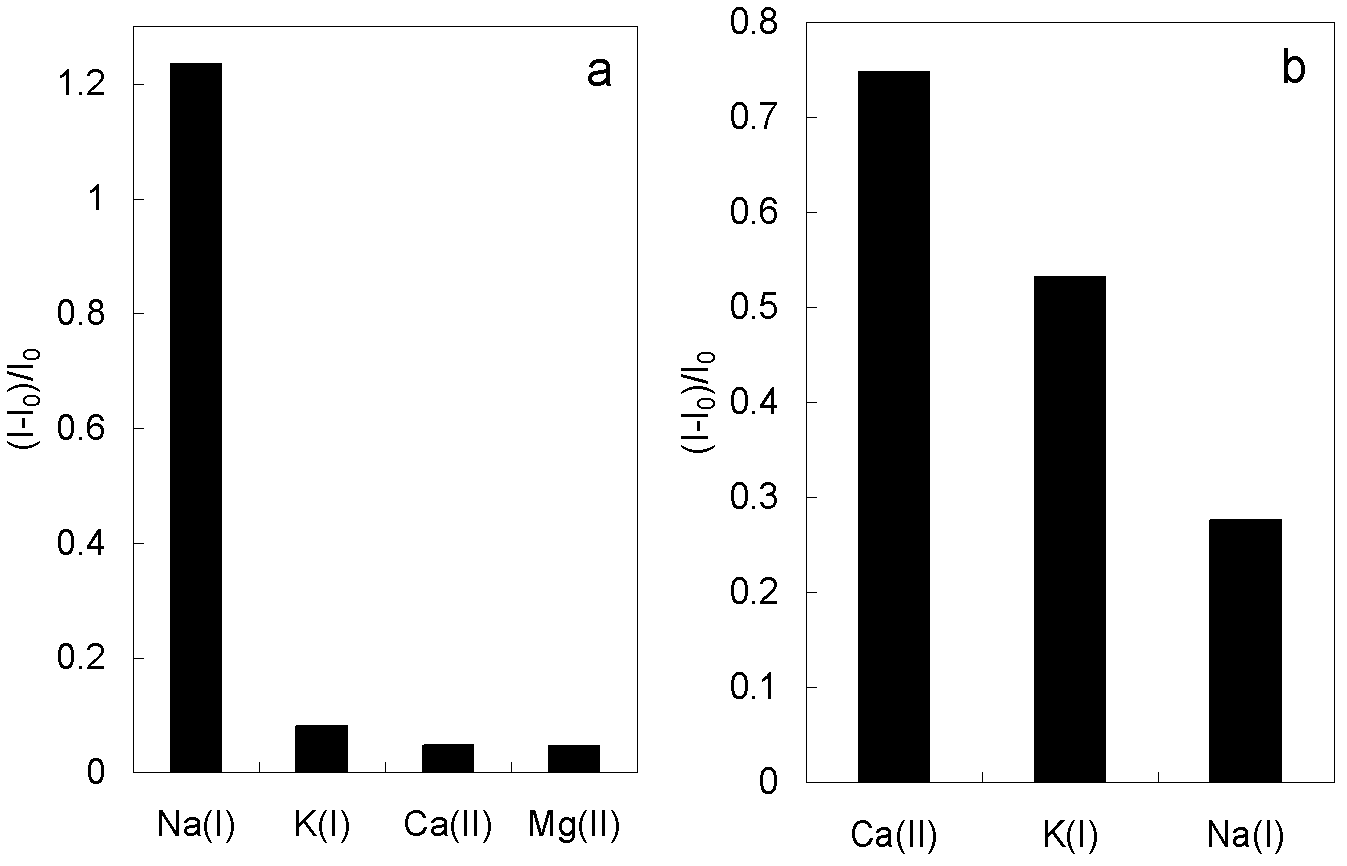

[0043] Example 2: Preparation of Optical Ion Sensing Membrane for Detecting Calcium Ions.

[0044] Each component was dispensed into a 100 mg mixture in the following weight percentages:

[0045] Chromogenic ionophore ETH5418 0.34%;

[0046] Ion exchanger NaTFPB 0.88%;

[0047] Calcium ionophore AU-1 (according to literature 26 Synthesis) 1.68%;

[0048] Up-conversion nanorods (made in Example 1) 2.17%;

[0049] PVC 31.74%;

[0050] Plasticizer DOS 63.19%.

[0051] The above mixture was dissolved with 1 mL of THF. The obtained solution was shaken vigorously for 0.5h and then sonicated for at least 0.5h to obtain a homogeneous solution. Use a pipette to take 50 μL of the mixed solution and spread it evenly on a clean rectangular quartz plate. Before use, let the solvent evaporate in the dark for 0.5 hours to obtain an optical ion sensing film for detecting calcium ions. The thickness of the film is 5-7 μm. .

[0052] When testing, insert the quartz plate with the optod...

Embodiment 3

[0053] Example 3: Preparation of an optical ion sensing membrane for the detection of sodium ions.

[0054] Each component was dispensed into a 100 mg mixture in the following weight percentages:

[0055] Chromogenic ionophore ETH5418 0.36%;

[0056] Ion exchanger NaTFPB 0.46%;

[0057] Sodium ionophore Na(X) (purchased from Fluka) 0.98%;

[0058] Up-conversion nanorods (made in Example 1) 2.05%;

[0059] PVC 31.96%;

[0060] Plasticizer NPOE 64.19%.

[0061] The above mixture was dissolved with 1 mL of cyclohexanone. The obtained solution was shaken vigorously for 0.5h and then sonicated for at least 0.5h to obtain a homogeneous solution. Use a pipette to take 50 μL of the mixed solution and spread it evenly on the top of the optical fiber. Before use, let the solvent evaporate in the dark for 0.5 hours to obtain an optical ion sensing membrane for detecting sodium ions. The thickness of the membrane is 5-7 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com