Modified lithium titanate and preparation method thereof

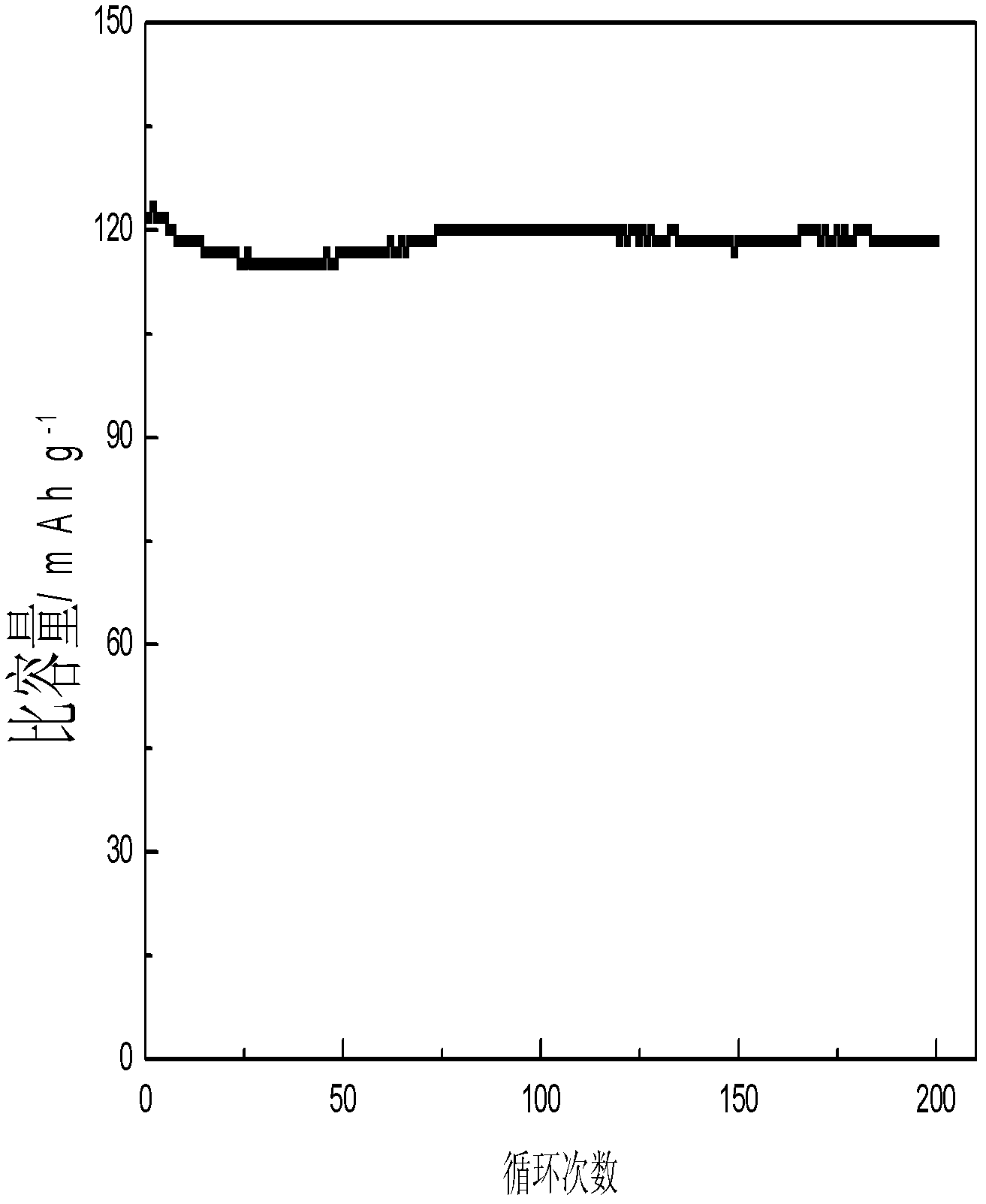

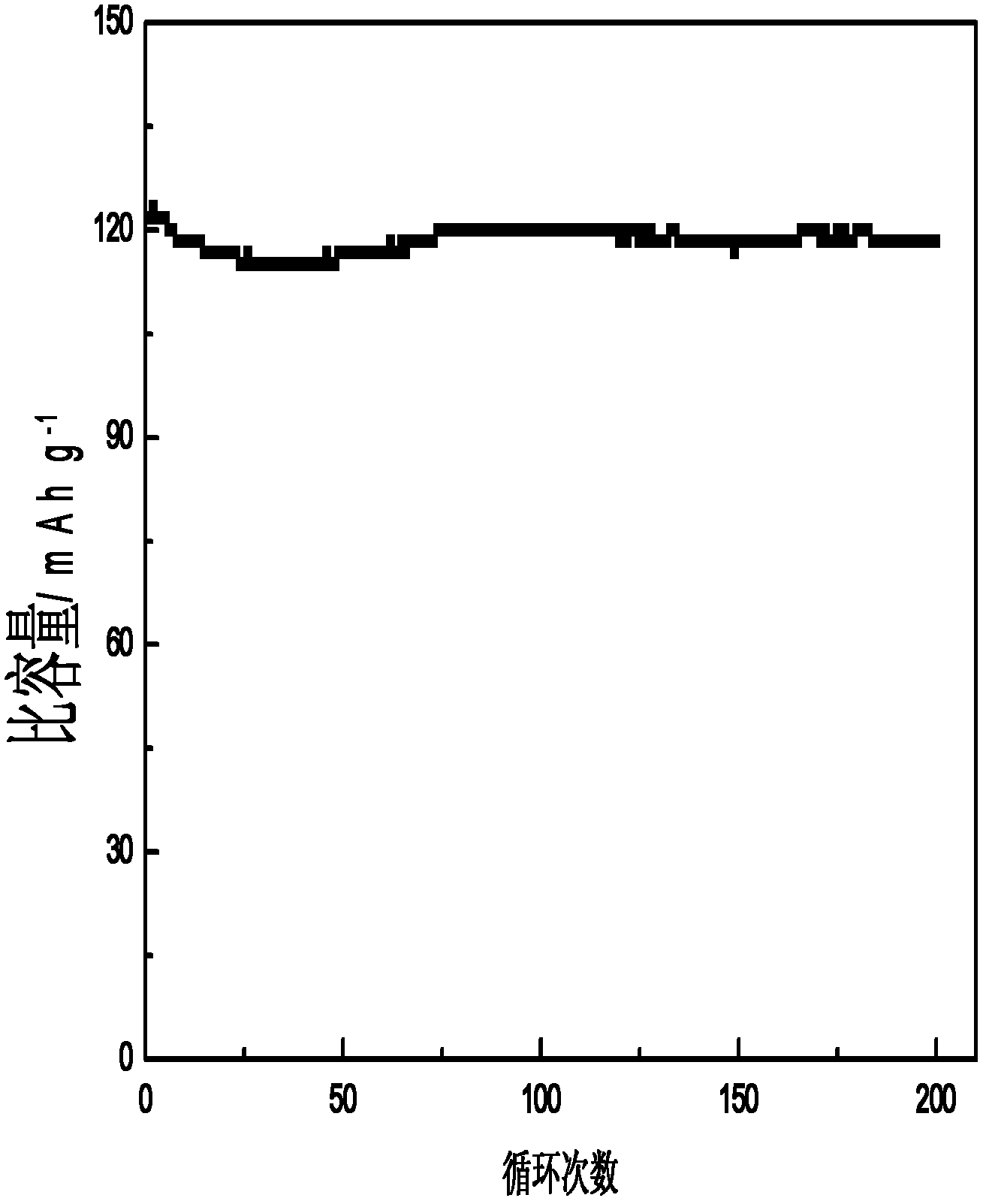

The unique technology of lithium titanate and lithium molybdate titanate is applied in the field of modified lithium titanate and its preparation, which can solve the problems of poor high rate performance, low battery voltage, poor electronic conductivity, etc., and achieve high specific capacity and cost. Moderate, stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A modified lithium titanate and preparation method thereof:

[0027] According to the molecular formula Li 4 Ti 4.98 Mo 0.02 o 12 Weigh respectively 0.8645g of titanium dioxide, 0.3469g of lithium carbonate, 0.0063g of molybdenum trioxide, 0.2145g of citric acid, ball mill for 10h, 800°C, calcined for 8h under a nitrogen atmosphere in a tube furnace, grind, and pass through a 150-mesh sieve to obtain the lithium ion Battery negative electrode material modified lithium titanate products.

Embodiment 2

[0029] A modified lithium titanate and preparation method thereof:

[0030] According to the molecular formula Li 4 Ti 4.98 Mo 0.02 o 12 Weigh 0.8645g of titanium dioxide, 0.2249g of lithium hydroxide, 0.0078g of ammonium molybdate, and 0.1548g of glucose, ball mill for 1h, calcine at 1000°C for 6h under a nitrogen atmosphere in a tube furnace, grind, and pass through a 150-mesh sieve to obtain the lithium ion Battery negative electrode material modified lithium titanate products.

Embodiment 3

[0032] A modified lithium titanate and preparation method thereof:

[0033] According to the molecular formula Li 4 Ti 4.98 Mo 0.02 o 12 Weigh 0.8645g of titanium dioxide, 0.6474g of lithium nitrate, 0.0078g of ammonium molybdate, 0.102g of sucrose and 0.0825g of glucose, ball mill for 20h, calcine at 600°C for 20h under a nitrogen atmosphere in a tube furnace, grind, pass through a 150-mesh sieve, and obtain the Described lithium ion battery negative electrode material modified lithium titanate product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com