Composite nano fiber support material, as well as preparation method and application in bone repairing aspect

A technology of composite nanofibers and scaffold materials, applied in the field of bone repair materials, to achieve the effect of facilitating deposition, simple and feasible preparation method, and enhancing mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

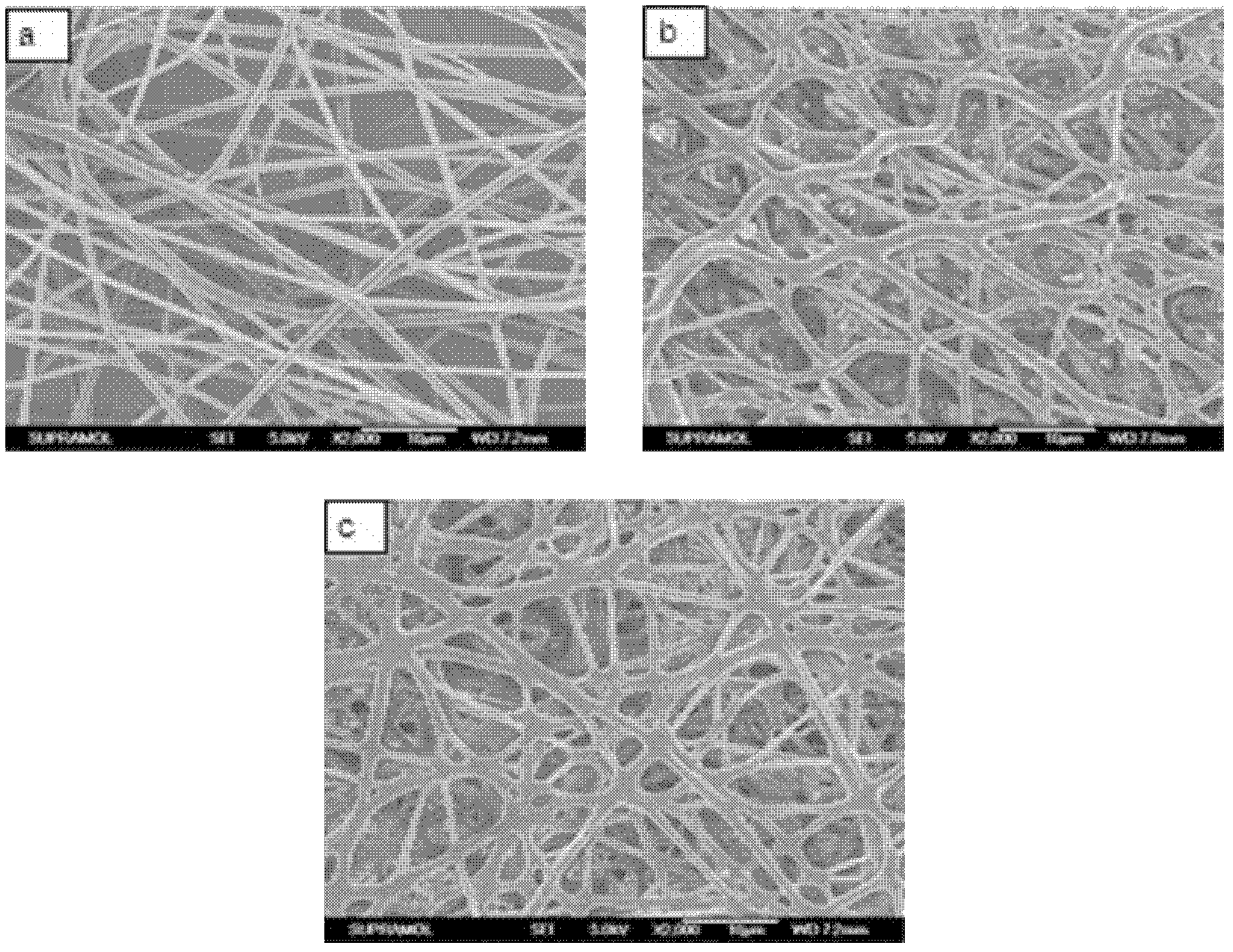

[0026] Dissolve 0.12 g of PLGA (molecular weight is 80,000, mass ratio of PLA to PGA is 85:15) in 2 mL of mixed solvent of chloroform and N,N-dimethylformamide (volume ratio is 1:1 ), after magnetic stirring for 4 hours, the chloroform and dimethylformamide mixed solution of PLGA was obtained; The PLGA nanofiber scaffolds were vacuum-dried for later use. Its fiber diameter is between 100nm and 200m, the fibers are interlaced, and there are a small amount of spindles, such as figure 1 (a).

Embodiment 2

[0028] Dissolve 0.006g of hydroxyapatite in a mixed solvent of 0.5mL chloroform and N,N-dimethylformamide (volume ratio is 1:1), and add it to the PLGA solution prepared in Example 1 after ultrasonic dissolution , and then spun by an electrospinning device (voltage 18V, distance 15cm) to prepare PLGA / HA nanofiber scaffolds, which were vacuum-dried for later use. Its fiber diameter is 50-100nm, such as figure 1 (b) shown.

Embodiment 3

[0030] Dissolve 0.012g of hydroxyapatite in a mixed solvent of 0.5mL chloroform and N,N-dimethylformamide (volume ratio is 1:1), and add it to the PLGA solution prepared in Example 1 after ultrasonic dissolution , and then spun by an electrospinning device (voltage 18V, distance 15cm) to prepare PLGA / HA nanofiber scaffolds, which were vacuum-dried for later use. The fiber diameter is 20-50nm, and contains more spindles, and the resulting fiber scaffold has larger pores, up to several microns, such as figure 1 (c) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com