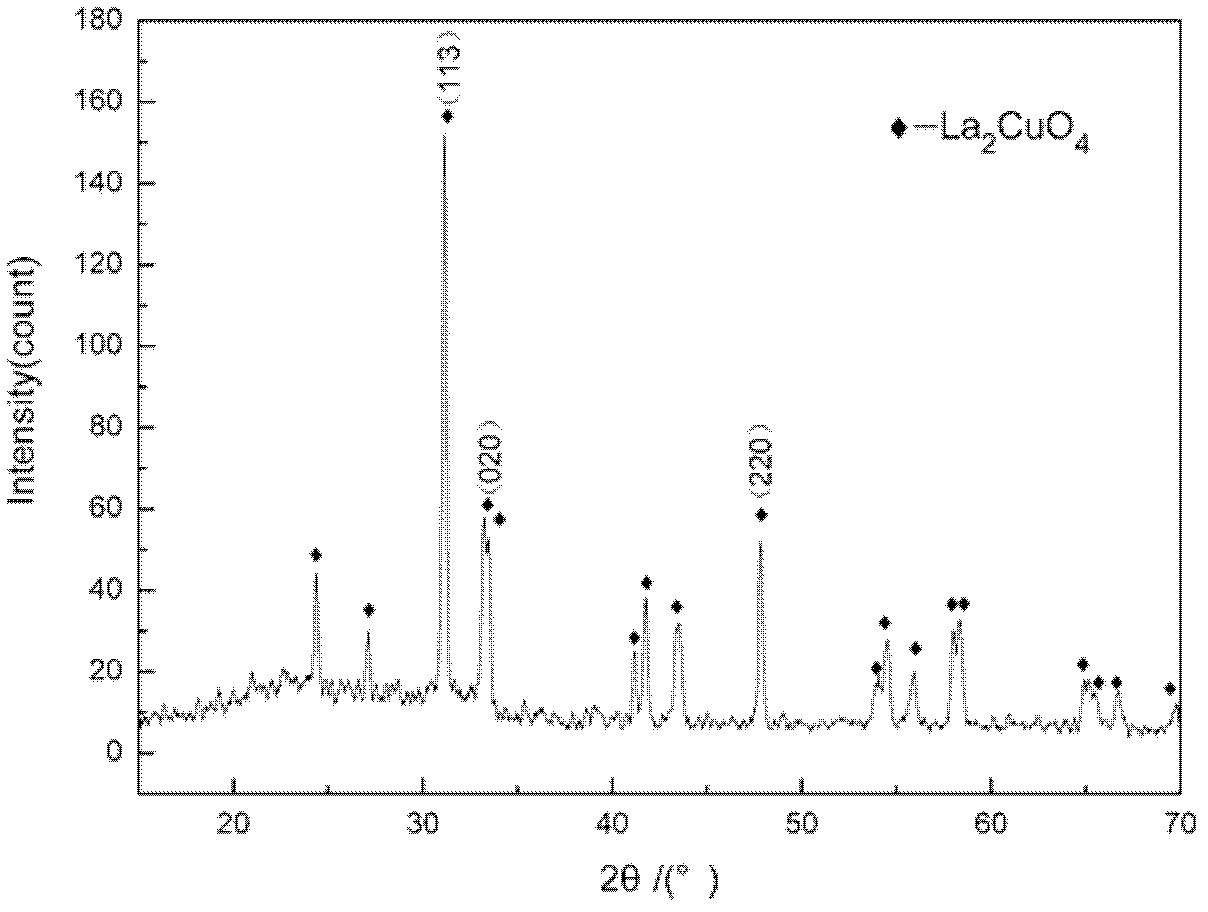

Method for preparing lanthanum cuprate (La2CuO4) film by using liquid-phase self-assembly method

A self-assembly method and lanthanum cuprate technology, applied in the field of La2CuO4 film preparation, can solve the problems of complex process, high equipment requirements, and difficulty in preparing high-quality epitaxial films, and achieve simple operation, low equipment requirements, and reaction process easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Cleaning of the substrate:

[0022] Rinse the cut silicon substrates with nitric acid, then put them in a beaker containing acetone and ethanol in turn, wash them with an ultrasonic cleaner, and then rinse with distilled water, and then dry them in a blast drying oven at 70°C. Piece A;

[0023] 2) OTS coating:

[0024] The dried substrate A was irradiated in an ultraviolet irradiator for 30 minutes and then placed in a mixed solution of octadecyltrichlorosilane (OTS) and toluene for 30 minutes. After removal, it was cleaned with acetone, and then with N 2 Blow dry, then put it in the ultraviolet irradiation instrument, irradiate with ultraviolet for 25 minutes to obtain substrate B;

[0025] Wherein, the mixed solution of octadecyltrichlorosilane (OTS) and toluene has a volume ratio of octadecyltrichlorosilane (OTS): toluene=1:99;

[0026] 3) Deposition of thin films

[0027] Will analyze pure lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), copper nitrate (Cu(NO 3 ) 3 ·3H 2 O), citri...

Embodiment 2

[0032] 1) Cleaning of the substrate:

[0033] Rinse the cut silicon substrates with nitric acid, then put them in a beaker containing acetone and ethanol in turn, wash them with an ultrasonic cleaner, and then rinse with distilled water, and then dry them in a blast drying oven at 50°C. Piece A;

[0034] 2) OTS coating:

[0035] The dried substrate A was irradiated in an ultraviolet irradiator for 120 minutes and then placed in a mixed solution of octadecyltrichlorosilane (OTS) and toluene for 20 minutes. After taking it out, it was cleaned with acetone, and then with N 2 Blow dry, then put it in the ultraviolet irradiation instrument, irradiate with ultraviolet for 35 minutes to obtain substrate B;

[0036] Wherein, the mixed solution of octadecyltrichlorosilane (OTS) and toluene has a volume ratio of octadecyltrichlorosilane (OTS): toluene=1:99;

[0037] 3) Deposition of thin films

[0038] Will analyze pure lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), copper nitrate (Cu(NO 3 ) 3 ·3H 2 O)...

Embodiment 3

[0042] 1) Cleaning of the substrate:

[0043] Rinse the cut silicon substrates with nitric acid, then put them in a beaker containing acetone and ethanol in turn, wash them with an ultrasonic cleaner, then rinse with distilled water, and then dry them in a blast drying oven at 100°C. Piece A;

[0044] 2) OTS coating:

[0045] The dried substrate A was irradiated in an ultraviolet irradiator for 20 minutes, and then placed in a mixed solution of octadecyltrichlorosilane (OTS) and toluene for 40 minutes. After taking it out, it was washed with acetone, and then with N 2 Blow dry, then put it in an ultraviolet irradiation instrument, irradiate with ultraviolet for 50 minutes to obtain substrate B;

[0046] Wherein, the mixed solution of octadecyltrichlorosilane (OTS) and toluene has a volume ratio of octadecyltrichlorosilane (OTS): toluene=1:99;

[0047] 3) Deposition of thin films

[0048] Will analyze pure lanthanum nitrate (La(NO 3 ) 3 ·6H 2 O), copper nitrate (Cu(NO 3 ) 3 ·3H 2 O), cit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com