Modification method of humic acid and application of product thereof in soil remediation

A black humic acid and modification technology, applied in the restoration of polluted soil, recycling technology, plastic recycling and other directions, can solve problems such as poor performance, can not achieve good repair effect, etc., achieve good effect and good repair ability , the effect of strong repair ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

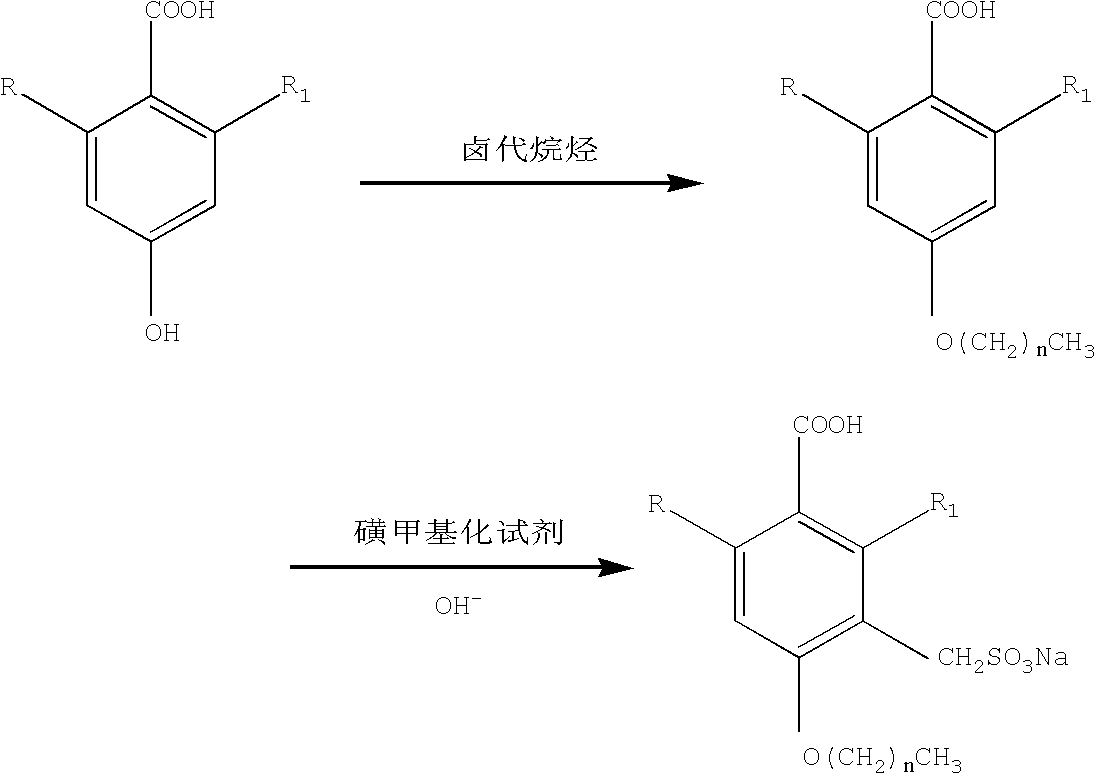

[0034] Take 10g of black humic acid and add it to a four-necked bottle, then add a certain amount of 15% potassium carbonate aqueous solution to completely dissolve the black humic acid, and adjust the pH value to 9-11, then raise the temperature to 65°C under stirring, Dissolving the alkylating agent in an ethanol solvent to form a mixed solution of the alkylating agent and ethanol, so that the mass percentage of the alkylating agent in the mixed solution is 10%, and the alkylating agent is an alkyl halide Hydrocarbons, the halogenated alkanes are chlorododecane straight-chain saturated alkanes, the mass ratio of the chlorododecane straight-chain saturated alkanes to black humic acid is 1:3, and the above-mentioned alkylating agent is started to be added dropwise The mixed solution with ethanol is subjected to an alkylation reaction, and the reaction time is 4 hours. After the reaction is completed, the temperature is cooled to room temperature and filtered. The filtration pro...

Embodiment 2

[0037] Take 10g of black humic acid and add it to a four-neck bottle, then add a certain amount of 20% sodium carbonate aqueous solution to completely dissolve the black humic acid, and adjust the pH value to 9-11, then raise the temperature to 70°C under stirring conditions, Dissolving the alkylating agent in a methanol solvent to form a mixed solution of the alkylating agent and methanol, so that the mass percentage of the alkylating agent in the mixed solution is 30%, and the alkylating agent is an alkyl halide Hydrocarbon, the halogenated alkane is hexadecane bromide linear saturated alkane, the mass ratio of the hexadecane bromide straight chain saturated alkane to black humic acid is 1:5, and the above-mentioned alkylating agent is started to be added dropwise The mixed solution with methanol was subjected to an alkylation reaction. The reaction time was 10 hours. After the reaction was completed, it was cooled to room temperature and filtered. The filtration process was ...

Embodiment 3

[0040] Take 10g of black humic acid and add it to a four-neck bottle, then add a certain amount of 35% sodium carbonate aqueous solution to completely dissolve black humic acid, and adjust the pH value to 9-11, and then raise the temperature to 70°C under the condition of stirring After first dissolving the alkylating agent in the propanol solvent, a mixed solution of the alkylating agent and propanol is formed, so that the mass percentage of the alkylating agent in the mixed solution is 15%. The reagent is a halogenated alkane, and the said halogenated alkane is a bromooctadecyl straight-chain saturated alkane, and the mass ratio of the bromooctadecane straight-chain saturated alkane to black humic acid is 1:5, and the above-mentioned The mixed solution of alkylating agent and propanol is carried out alkylation reaction, and the reaction time is 10 hours, cools down to room temperature and filters after reaction, collects filtrate, begins to carry out vacuum distillation to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com