Ceramic material with sound-absorbing and plant-cultivating functions and preparation method thereof

A technology for ceramic materials and plants, applied in the field of preparation of ceramic materials, can solve the problems of complicated construction, high construction cost, blockage of sewers, etc., and achieve the effects of convenient construction and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The steps are:

[0027] (1) In terms of parts by mass, weigh 5 parts of clay, 10 parts of quartz, 12 parts of limestone, 6 parts of feldspar, 60 parts of construction waste, 4 parts of slag, and 3 parts of cinder; binder carboxymethyl cellulose 7 parts of sodium, 3 parts of gelling agent konjac flour and 1 part of xanthan gum, 5 parts of foaming agent sodium dodecylbenzene sulfonate;

[0028] (2) Dry ball milling for 180 minutes, add 28 parts of water, and then wet stirring for 120 minutes;

[0029] (3) Grouting;

[0030] (4) Dry at 50°C for 12 hours in an air atmosphere;

[0031] (5) Firing at 1260°C for 30min in an air atmosphere.

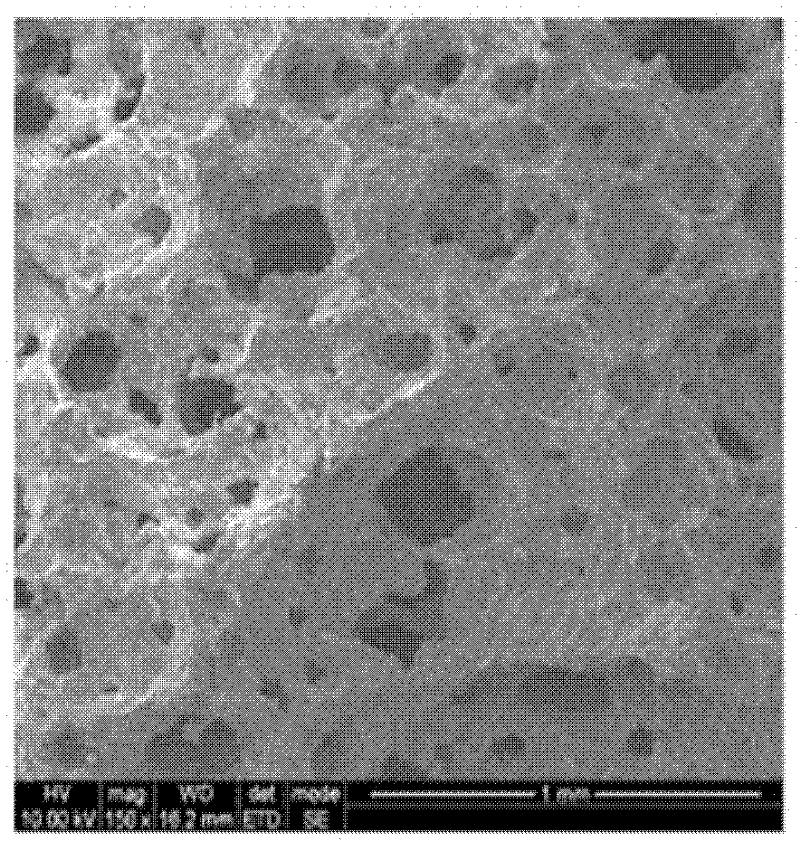

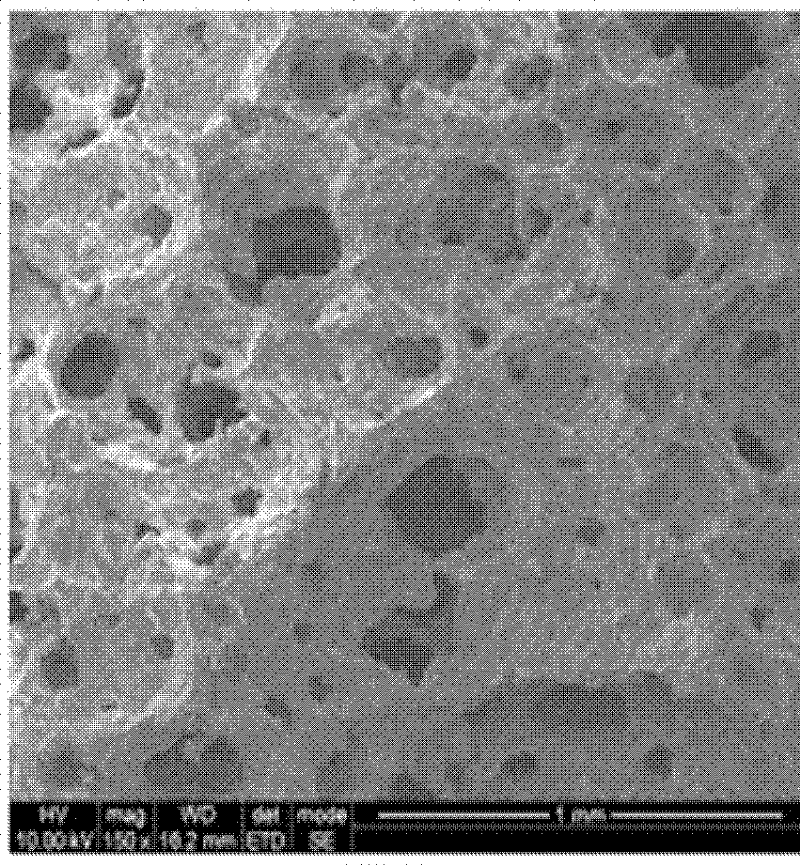

[0032] The prepared ceramics have an apparent porosity of 76%, a pore size distribution of 35~319μm, a water absorption rate of 125%, and a bulk density of 0.72g / cm 3 , the compressive strength is 2.6MPa, the refractoriness is greater than 1200°C, and the average sound absorption coefficient is 0.65 (average values at frequencies of ...

Embodiment 2

[0034] The steps are:

[0035] (1) In terms of parts by mass, weigh 22 parts of quartz, 12 parts of feldspar, 3 parts of urban sludge, 3 parts of dredging mud, 50 parts of ceramic waste, 4 parts of construction waste, 4 parts of slag, and 2 parts of cinder; 0.5 part of binder polyvinyl alcohol, 0.5 part of dispersant ammonium citrate;

[0036] (2) Add 19 parts of water and wet ball mill for 30 minutes;

[0037] (3) Powder pressing under 400MPa;

[0038] (4) Dry at 120°C for 24 hours in an air atmosphere;

[0039] (5) Firing at 800°C for 360min under microwave conditions.

[0040] The prepared ceramics have an apparent porosity of 67%, a pore size distribution of 17~260μm, a water absorption rate of 73%, and a bulk density of 0.91g / cm 3 , The compressive strength is 5.6MPa, the refractoriness is greater than 1000°C, and the average sound absorption coefficient is 0.49 (the average value when the frequency is 250, 500, 1000, 2000Hz, the same below). Bermudagrass is used for...

Embodiment 3

[0042] The steps are:

[0043] (1) In terms of parts by mass, weigh 45 parts of clay, 2 parts of feldspar, 3 parts of ceramic waste, 50 parts of municipal sludge; 6 parts of dispersant sodium tripolyphosphate;

[0044] (2) Dry stirring for 5 minutes;

[0045] (3) Powder pressing under 0.1MPa;

[0046] (4) Dry at 75°C for 1 hour in a vacuum atmosphere;

[0047] (5) Firing at 1350°C for 3 minutes in an air atmosphere.

[0048] The prepared ceramics have an apparent porosity of 83%, a pore size distribution of 42~830μm, a water absorption rate of 168%, and a bulk density of 0.56g / cm 3 , compressive strength 2.1MPa, refractoriness greater than 1250 ℃, average sound absorption coefficient 0.77. It is used for planting Zoysia fine-leaved grass, which grows well.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size distribution | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com