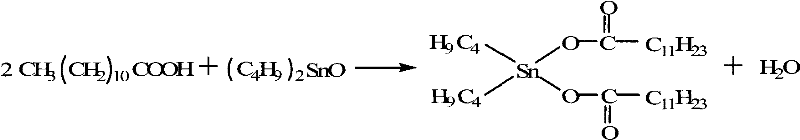

Method for preparing dibutyltin dilaurate catalyst

A technology of dibutyltin laurate and dibutyltin oxide, applied in the direction of tin organic compounds, can solve the problems of incomplete reaction of lauric acid, high production cost, many side reactions, etc. The effect of high utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the dibutyltin dilaurate catalyst that the embodiment of the present invention provides comprises the following steps:

[0022] A. Feed lauric acid and dibutyltin oxide in a molar ratio of 1.7 to 2:1 (preferably a molar ratio of 1.82 to 1.9:1), stir and heat. When the temperature rises to 50°C, the reaction system begins to Negative pressure;

[0023] B. Continue heating, raise the temperature to 80°C-88°C, maintain the system temperature for continuous reaction for 2 hours, then stop the negative pressure, add acetic anhydride, and continue stirring for 1 hour;

[0024] C. The solution obtained by the reaction is compounded with additives according to a certain mass ratio, and finally the finished product is obtained. The compounding aid is at least one of acetic acid, DOP (dioctyl phthalate), phenyl ether, dodecylbenzene, and coconut oil. When the compounding aid of the solution included acetic acid, the acetic acid and the solution The mas...

Embodiment 1

[0029] A. Weigh 480g of lauric acid and 300g of dibutyltin oxide (molar ratio is 1.99:1), put them in a 1000mL three-neck flask, then start stirring and heating to raise the temperature. When the temperature rises to 50°C, the system starts to have negative pressure;

[0030] B. Continue heating, raise the temperature to 80°C, continuously remove the moisture generated by the reaction through negative pressure, maintain the system temperature for continuous reaction for 2 hours, then stop the negative pressure, add a certain amount of acetic anhydride into the three-necked flask, and continue to stir for 1 hour;

[0031] C, after cooling, get the solution that 50g reacts to obtain, add compounding auxiliary agent: 1.8g acetic acid, 2.8gDOP and 5.4g coconut oil (the mass percent of acetic acid, DOP and coconut oil and solution are respectively 3.0%, 4.7% and 9.0%) %), finally get the finished product. Under the condition that the temperature is 2°C, the finished product is no...

Embodiment 2

[0033] In the present embodiment, except that the following circumstances are different from embodiment 1, all the other are the same as embodiment 1: 460g of lauric acid and 300g of dibutyltin oxide are weighed in step A (the molar ratio is 1.91: 1), heated in step B The temperature was raised to 85°C, and 100 g of the reaction product was taken in Step C, and the compounding aids added were 9.0 g of DOP and 3.5 g of phenyl ether (the mass percentages of DOP and phenyl ether to the solution were 8.0% and 3.1%, respectively).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com