Water-based honing liquid and honing method for using same

A honing fluid and water-based technology, which is applied in the field of water-based honing fluid, can solve the problems such as large error, serious consumption of honing fluid, pollution of honing fluid, etc. Excellent cooling performance and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

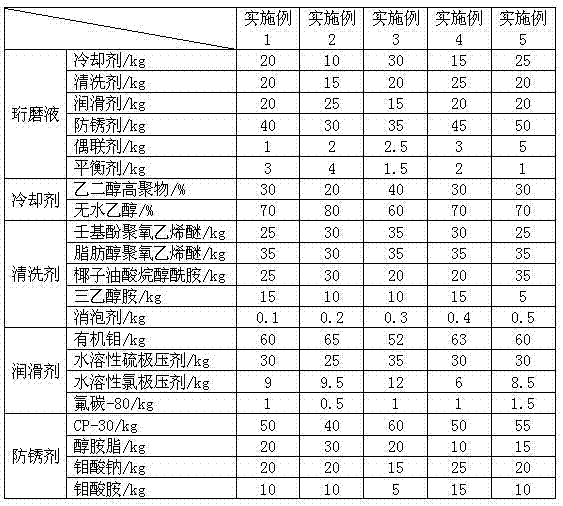

Embodiment 1~5

[0028] Prepare honing fluid as follows:

[0029] a. Preparation of coolant: Soak the ethylene glycol polymer in absolute ethanol for 12 hours at room temperature, stir thoroughly, and prepare the obtained transparent liquid for later use after 24 hours.

[0030] b. Preparation of cleaning agent: Add nonylphenol polyoxyethylene ether into the reaction tank, and add fatty alcohol polyoxyethylene ether, coconut oleic acid alkanolamide, and triethanolamine under the condition of 30~35°C to dissolve After it is complete, add the defoamer dropwise, stir until there is no foam, and set aside.

[0031] c. Preparation of lubricant: Add organic molybdenum into the reaction tank and stir, raise the temperature to 80~90°C, add water-soluble sulfur extreme pressure agent and water-soluble chlorine extreme pressure agent in turn under the condition of stirring, keep stirring for 4~6h and stop Stir, cool down to 70°C, slowly add fluorocarbon-80 under the condition of stirring, stir evenly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com