Recombination blue-green alga for producing lactic acid as well as preparation method and applications thereof

A technology of cyanobacteria and lactic acid, applied in the biological field, can solve the problems of increasing global food, exacerbating the shortage of fossil energy, and the inability to achieve sustainable development of renewable energy, and achieve the effect of avoiding the use of organic matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

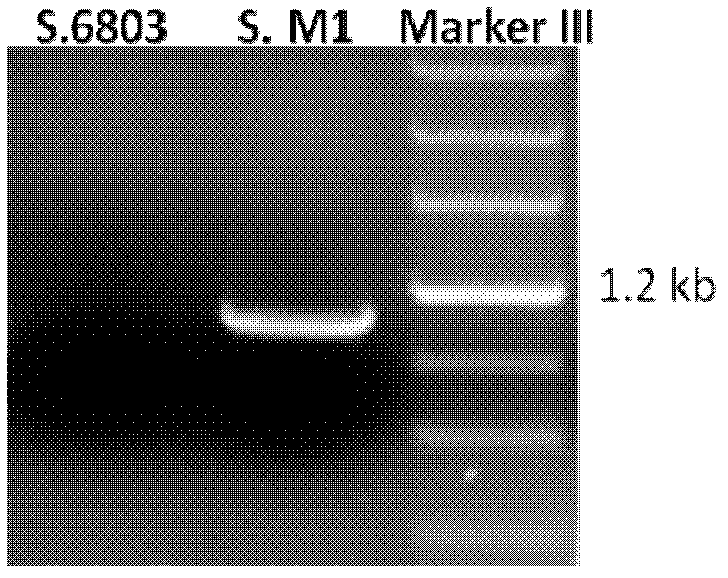

[0065] Embodiment 1, the construction of recombinant cyanobacteria S.M1

[0066] Establishment of an optically pure D-lactate synthesis pathway in the freshwater cyanobacterium Synechocystis sp. PCC 6803. Since there is pyruvate, the immediate precursor of lactic acid synthesis, in cyanobacteria cells, D-lactate dehydrogenase (D-LDH), which catalyzes the conversion of pyruvate into D-lactate, can be overexpressed in cyanobacteria cells to realize the production of D-lactate by cyanobacteria.

[0067] 1. Construction of recombinant plasmid pMD-Dldh (Synechocystis D-ldh homologous recombination integration expression vector)

[0068] 1. Acquisition of D-lactate dehydrogenase encoding gene Dldh

[0069] The D-lactate dehydrogenase coding gene Dldh was synthesized after entrusting Shanghai Bioengineering Co.

[0070] The amino acid sequence of D-lactate dehydrogenase is sequence 3 in the sequence listing, and its nucleotide sequence is 608-1788 nucleotides from the 5' end of seq...

Embodiment 2

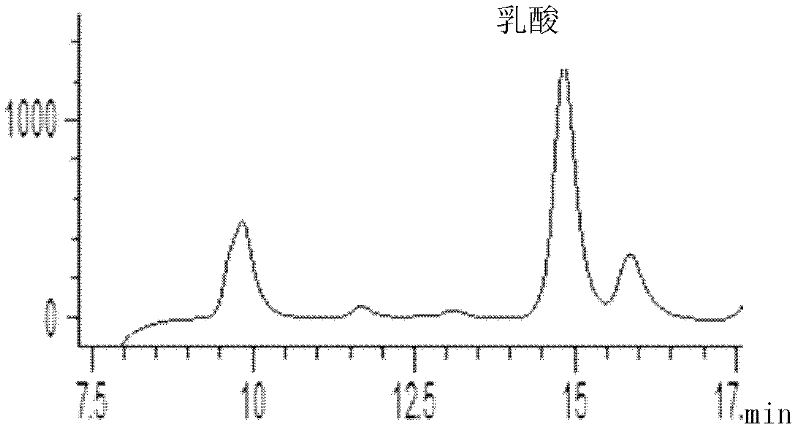

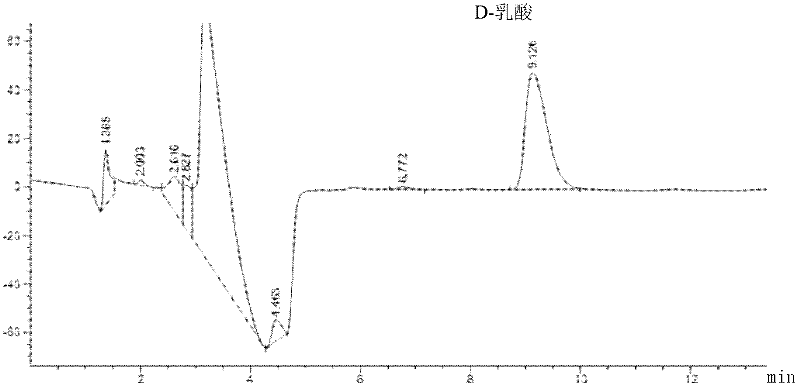

[0103] Embodiment 2, recombinant cyanobacteria S.M1 produces optically pure D-lactic acid

[0104] 1. Preparation of optically pure D-lactic acid

[0105] method one,

[0106] Lactic acid is usually produced during fermentation. Therefore, cells are cultured under normal culture conditions. When the biomass accumulates to a certain extent, dark fermentation culture is used for induction.

[0107] 1. Illumination cultivation

[0108] The above-mentioned recombinant cyanobacteria S.M1 obtained by Example 1 was placed in a light incubator and shaken to the late logarithmic growth period (making its cell density reach OD 730 =1.5); culture time is 7 days; temperature is 30°C, light intensity is 100μm / m 2 · s, the oscillation frequency is 130r / min, the culture medium is BG-11 (using inorganic carbon as the sole carbon source), and the light culture product is obtained.

[0109] 2. Dark cultivation

[0110] Then, the light culture product was subjected to dark static culture fo...

Embodiment 3

[0130] Embodiment 3, the construction of recombinant cyanobacteria S.M2

[0131] Synthetic pathway of optically pure D-lactic acid was established in seawater cyanobacterium Synechococcus sp. PCC 7002. Since there is pyruvate, the immediate precursor of lactic acid synthesis, in cyanobacteria cells, D-lactate dehydrogenase (D-LDH), which catalyzes the conversion of pyruvate into D-lactate, can be overexpressed in cyanobacteria cells to realize the production of D-lactate by cyanobacteria. Since there is lactate dehydrogenase (LDH) coding gene ldh in Synechococcus sp. 7002, the production of optically pure lactic acid D-lactic acid by seawater cyanobacteria can be achieved by expressing D-lactate dehydrogenase with ldh as the insertion site.

[0132] 1. Construction of recombinant plasmid pMD-Dldh (Synechococcus D-ldh homologous recombination integration expression vector)

[0133] 1. Acquisition of D-lactate dehydrogenase encoding gene Dldh

[0134] The D-lactate dehydrogena...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com