Composite anode material for lithium ion battery

A composite positive electrode material and lithium-ion battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of low diffusion coefficient of lithium ions, achieve broad application prospects, improve lithium ion diffusion performance, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

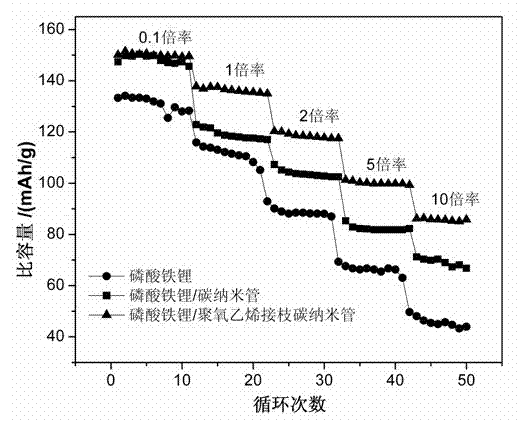

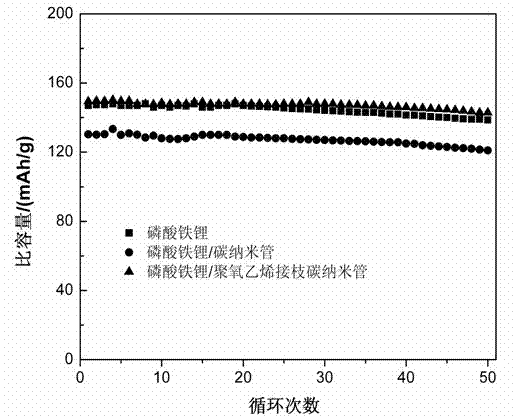

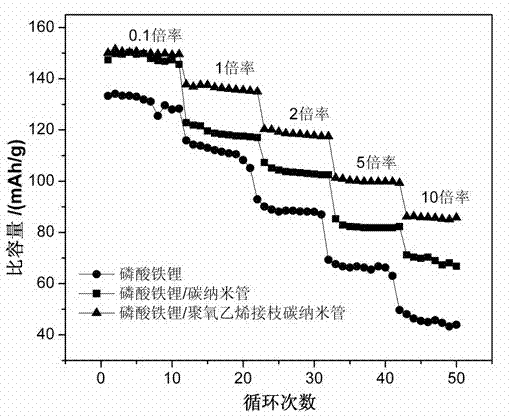

Examples

Embodiment 1

[0021] Put 1g of carbon nanotubes in a mixture of 75ml of concentrated nitric acid and 25ml of concentrated sulfuric acid, reflux at 90°C for 12h, cool to room temperature and dilute with a large amount of deionized water, then filter and wash repeatedly with deionized water until the filtrate is neutral. Dry to obtain acidified carbon nanotubes. The acidified carbon nanotubes were placed in 5 mL of anhydrous N,N-dimethylformamide, and after ultrasonic oscillation at room temperature for 40 min, 100 g of thionyl chloride was added, stirred mechanically and heated to 80° C. for reflux reaction for 24 h. After cooling to room temperature, the filtrate was filtered and washed repeatedly with anhydrous tetrahydrofuran until the filtrate was colorless, and the solid matter was vacuum-dried at 50° C. for 5 h to obtain acyl chloride carbon nanotubes. Disperse carbonyl chloride carbon nanotubes in 25mL of anhydrous N,N-dimethylformamide, ultrasonically shake at room temperature for 40...

Embodiment 2

[0024]Put 1g of carbon nanotubes in a mixture of 25ml of concentrated nitric acid and 75ml of concentrated sulfuric acid, reflux at 100°C for 10h, cool to room temperature and dilute with a large amount of deionized water, then filter, wash repeatedly with deionized water until the filtrate is neutral, and dry acidified carbon nanotubes. The acidified carbon nanotubes were placed in 50 mL of anhydrous N,N-dimethylacetamide, and after ultrasonic oscillation at room temperature for 20 min, 200 g of oxalyl chloride was added, mechanically stirred and heated to 60° C. for reflux reaction for 36 h. After filtration and repeated washing with anhydrous tetrahydrofuran until the filtrate was colorless, the solid matter was vacuum-dried at 80° C. for 0.5 h to obtain acyl chloride carbon nanotubes. Disperse carbonyl chloride nanotubes in 50mL of anhydrous N,N-dimethylacetamide, ultrasonically shake at room temperature for 20min, add 50g of polyoxypropylene, heat to 120°C under nitrogen ...

Embodiment 3

[0027] Place 1g of carbon nanotubes in a mixture of 100ml of concentrated nitric acid and 100ml of concentrated sulfuric acid, reflux at 120°C for 2 hours, cool to room temperature, dilute with a large amount of deionized water, then filter, wash repeatedly with deionized water until the filtrate is neutral, and dry acidified carbon nanotubes. The acidified carbon nanotubes were placed in 25 mL of anhydrous tetrahydrofuran, and after ultrasonic oscillation at room temperature for 30 min, 150 g of phosphorus trichloride was added, mechanically stirred and heated to 90° C. for reflux reaction for 12 h. After the reaction was completed, the solid matter was vacuum-dried at 70° C. for 3 h to obtain carbonyl chloride carbon nanotubes after suction filtration and repeated washing with anhydrous tetrahydrofuran. Disperse carbonyl chloride carbon nanotubes in 5 mL of anhydrous tetrahydrofuran, ultrasonically oscillate at room temperature for 40 minutes, add random copolymer of oxyethy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com