Preparation process of direct yoghurt starter for liquid nitrogen deep-cold granulation

A technology of yogurt starter and preparation process, which is applied in the field of preparation of liquid nitrogen cryogenic granulation direct-injection yogurt starter, can solve the problems of long preparation time, strain damage, long resurrection time, etc., and achieve simple preparation process, bacteria A high-energy, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] Example 1 Liquid nitrogen cryogenic granulation direct throw type yogurt starter (Streptococcus thermophilus)

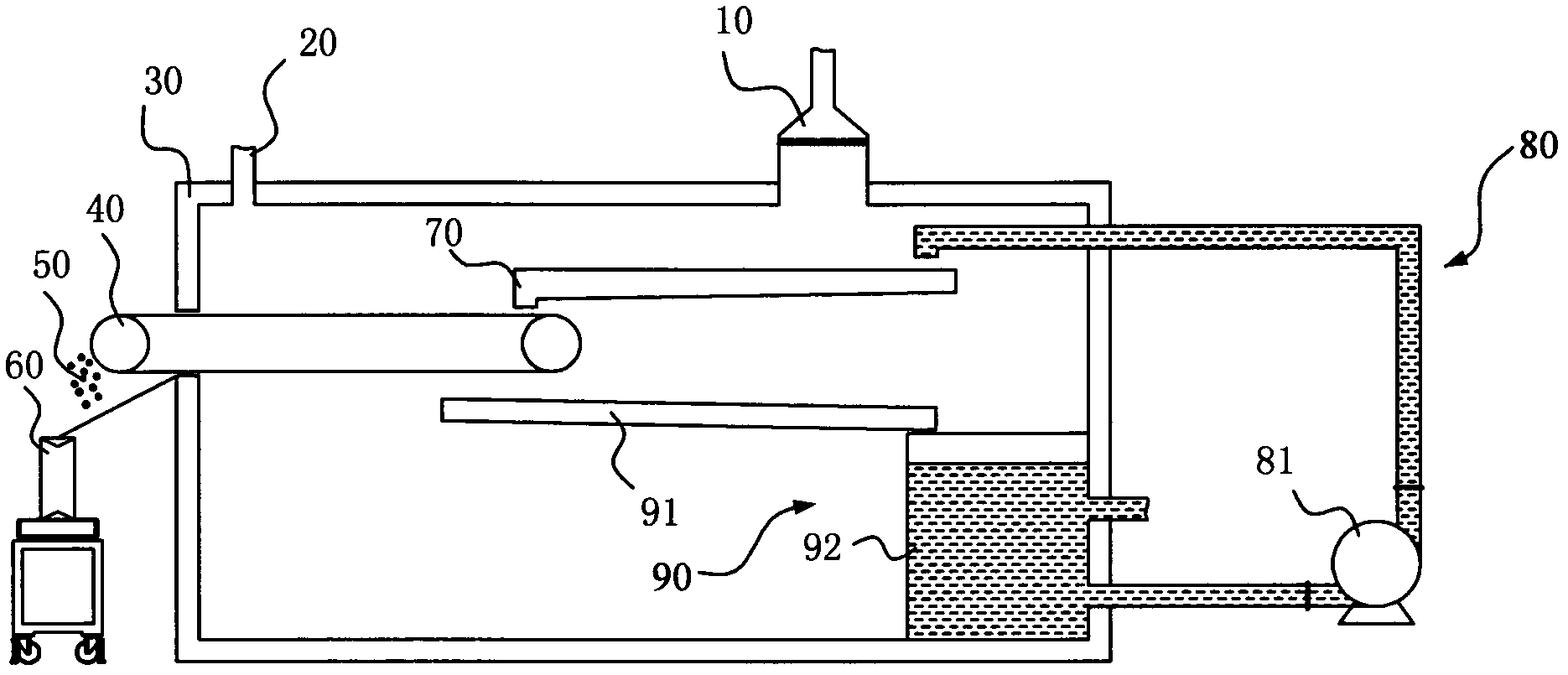

[0070] The schematic diagram of the preparation process of the lactic acid bacteria direct-throwing type starter of the present embodiment is as follows Figure 6 As shown, the device disclosed in the device embodiment is used.

[0071] The preparation method comprises the following steps:

[0072] (1) According to the culture conditions suggested by the manufacturer, inoculate the M17 culture medium containing Streptococcus thermophilus strain (derived from Danisco’s commercial strain) cultivated in the laboratory at an inoculation amount of 3%. In 8L sterilized M17 medium, carry out the first expansion culture, culture temperature 45 ℃, culture time 6h; then inoculate according to 2% in 392L aqueous solution containing 12% sterilized skim milk powder, carry out the second expansion culture , the cultivation temperature was 44°C, the cultivation time was 16...

Embodiment 2

[0077] Example 2 Liquid nitrogen cryogenic granulation direct throw type yogurt starter (Lactobacillus bulgaricus)

[0078] This embodiment uses the device disclosed in the device embodiment.

[0079] The preparation method comprises the following steps:

[0080] (1) According to the culture conditions suggested by the manufacturer, inoculate 2.5L of MRS culture medium containing Lactobacillus bulgaricus strain (derived from Danisco commercial strain) obtained in the laboratory, and inoculate at an inoculation volume of 1%. In 247.5L sterilized MRS medium, carry out the first expansion culture, culture temperature 37 ℃, culture time 24h; The fermented liquid after expansion culture is put into 4750L sterilized MRS medium according to the inoculum amount of 5%, carry out the second time 2 times of expansion, culture temperature 37 ℃, culture time 18h. During the expansion process, the fermenter is filled with nitrogen to maintain anaerobic fermentation;

[0081] (2) The mate...

Embodiment 3

[0085] Example 3 Liquid nitrogen cryogenic granulation direct throw type yogurt starter (Lactobacillus casei)

[0086] This embodiment uses the device disclosed in the device embodiment.

[0087] The preparation method comprises the following steps:

[0088] (1) According to the culture conditions suggested by the manufacturer, inoculate the MRS medium containing Lactobacillus casei LC2W strain (CGMCC No.0828, Guangming Dairy Co., Ltd.) obtained in the laboratory at an inoculum size of 3%. In 2L sterilized MRS medium, carry out the first expansion culture, culture temperature 30 ℃, culture time 8h; then inoculate 48L sterile 3% hydrolyzed milk protein aqueous solution according to 4%, carry out the second expansion culture Cultivate at a temperature of 32°C, for 16 hours, and keep the pH constant at 6.5; the fermented broth after expansion was added to 2450L of sterilized 15% hydrolyzed milk protein aqueous solution according to the inoculum size of 2%, and the third expansio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com