Method for uploading cefazolin sodium medicine film on micro-arc oxidation titanium implant

A cefazolin sodium, micro-arc oxidation technology, applied in prosthesis, medical science, coating and other directions, can solve the problems of poor biological activity, low binding strength, long healing time, etc., to improve binding ability and improve biological activity , Improve the effect of surface biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: the method for loading cefazolin sodium drug film on the micro-arc oxidation titanium implant of the present embodiment comprises the following four steps:

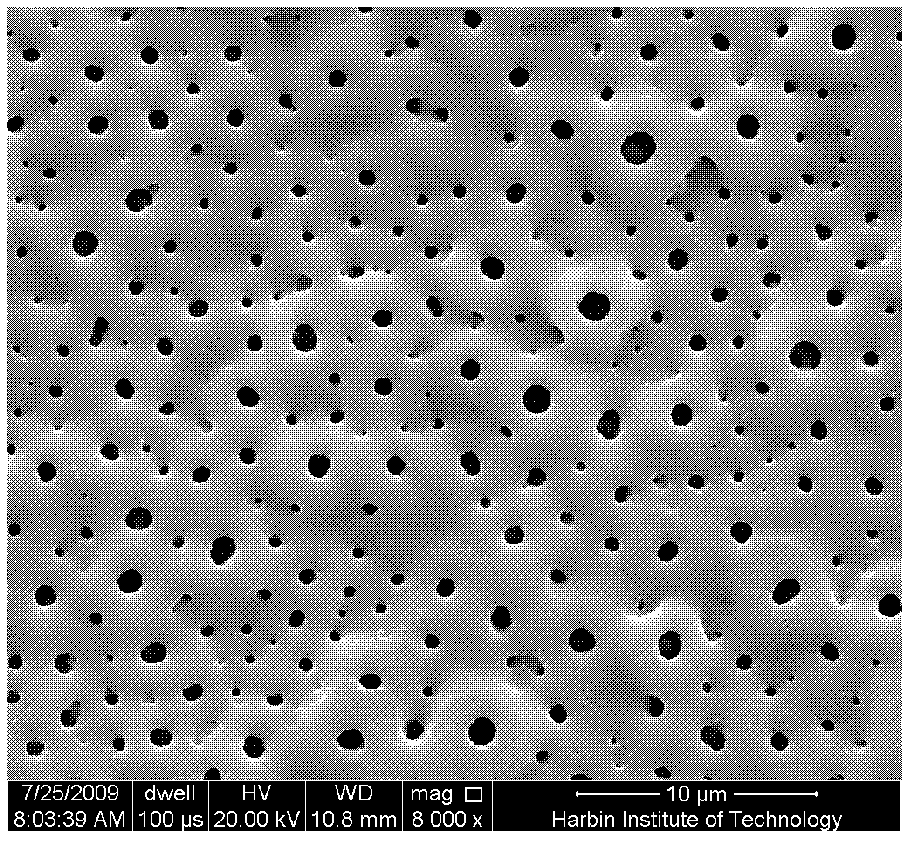

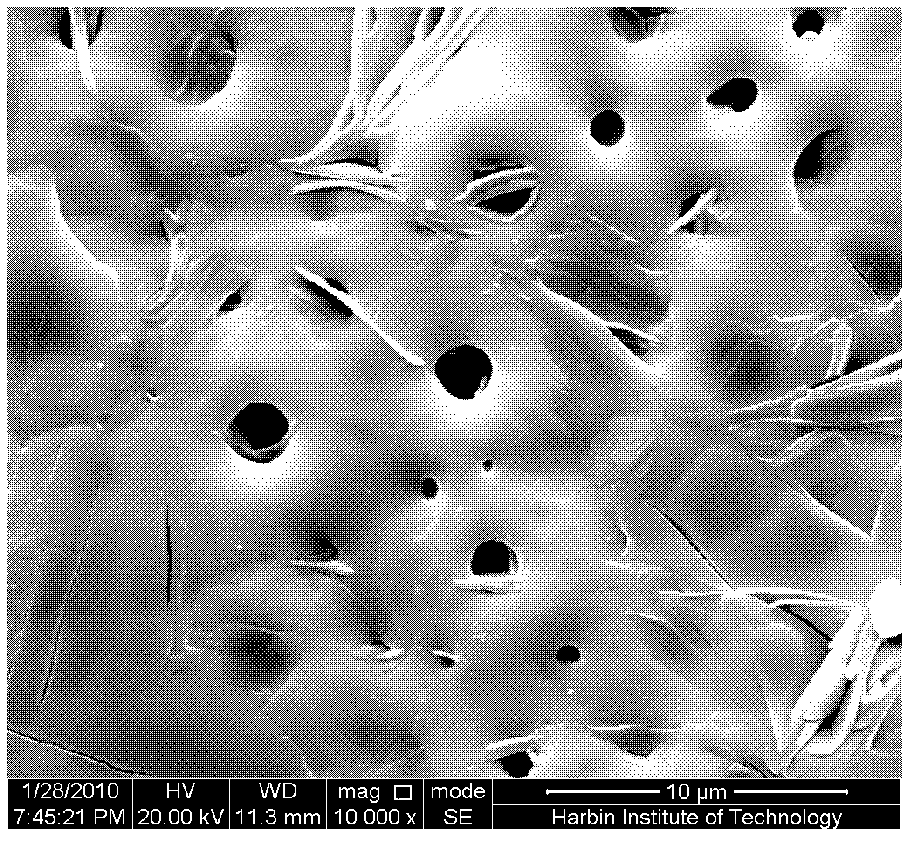

[0019] Step 1: Do micro-arc oxidation. Place the titanium implant in a stainless steel tank containing an alkaline electrolyte, use the titanium implant as the anode, and the stainless steel tank as the cathode; during the oxidation process, the temperature of the tank is controlled by the cooling system figure 1 and figure 2 ), the thickness of the micro-arc oxidation coating is 3-10 microns.

[0020] Step 2: cefazolin sodium injection is dissolved in deionized water, and a certain concentration of cefazolin sodium aqueous solution is prepared.

[0021] Step 3: immerse the micro-arc oxidized titanium substrate in an aqueous solution of cefazolin sodium for a certain period of time.

[0022] Step 4: Take out the micro-arc oxidation titanium substrate soaked in cefazolin sodium, put it in ...

specific Embodiment approach 2

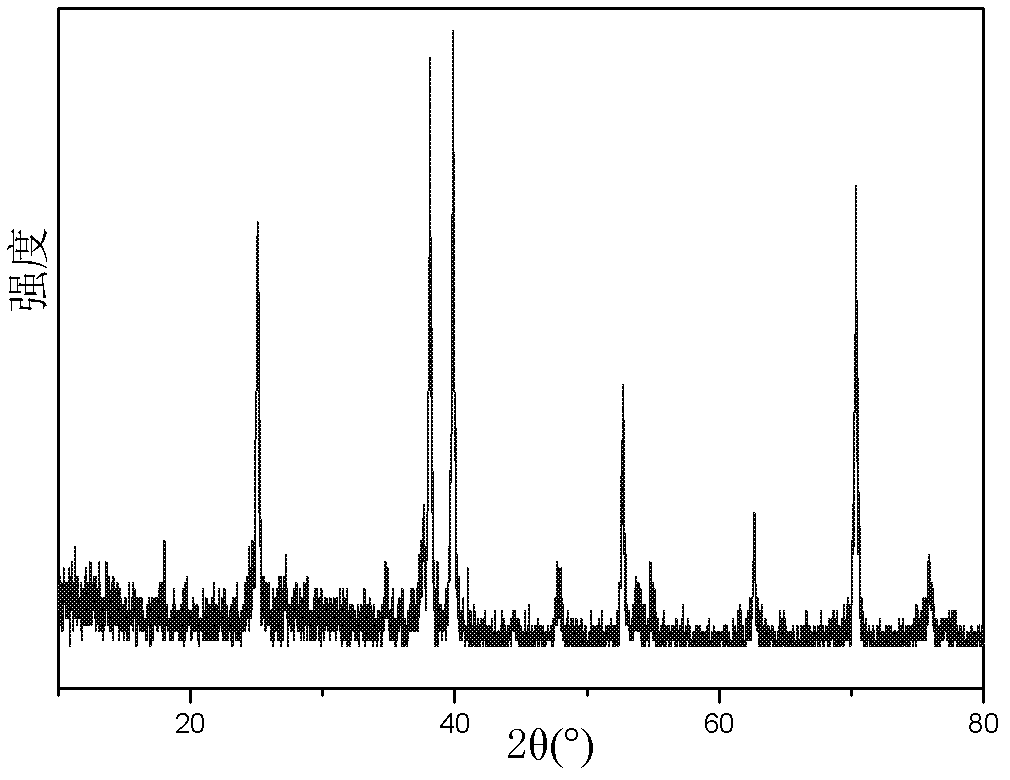

[0030] Embodiment 2: This embodiment is different from Embodiment 1 in that the energy in the oxidation process is provided by an adjustable high-voltage and high-frequency bipolar pulse power supply. The pulse parameters are voltage 200-500V, frequency 400-800Hz, duty cycle 4~10%. Other steps are the same as in the first embodiment. When the applied voltage exceeds the critical voltage of the insulating film on the titanium surface placed in the electrolyte, the spark discharge generated on the surface of the part will oxidize the matrix and form dense TiO 2 Oxide coating, by controlling the composition of the electrolyte, trace elements that are beneficial to the living body can be introduced into the surface of the oxide layer through the oxidation process of the material, and then the sample treated by micro-arc oxidation is immersed in a certain concentration of cefazolin sodium In the aqueous solution, the soaked sample is subsequently taken out, heated and dried to obt...

specific Embodiment approach 3

[0031] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the energy of the micro-arc oxidation process is provided by an adjustable high-voltage and high-frequency bipolar pulse power supply, the pulse voltage is 200-500V, the frequency is 400-800Hz, The duty ratio is 4-20%, and the solution temperature is 0-50°C. Within the above selected electrical parameters of the micro-arc oxidation, the thickness of the coating can reach 3-10 microns after micro-arc oxidation for 5 minutes. Other steps are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com