Crotonic acid and acrylic acid copolymer modified ferroferric oxide nano granules with silicon structure as well as preparation and application thereof

A technology of ferroferric oxide and nanoparticles, applied in other chemical processes, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as heavy metal hazards, achieve simple equipment, reduce costs, and have large adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Fe 3 o 4 Preparation of @APS@AA-co-CA nanomaterial adsorbent.

[0033] First, Fe 3 o 4 Preparation of magnetic nanoparticles: 5.2g FeCl 3 .6H 2 O, 2.0g FeCl 2 .4H 2 O and 0.85ml of concentrated hydrochloric acid were dissolved in 25ml of deionized water. The solution was added dropwise to 250 ml of deionized water containing 60 g of NaOH, and mechanically stirred at 80° C. for 30 min. Separation of Fe with a strong magnet 3 o 4 The magnetic nanoparticles were washed three times with 300ml deionized water and absolute ethanol respectively, and dried under vacuum at room temperature.

[0034] Next, the preparation of crotonic acid and acrylic acid copolymer (AA-co-CA): 6.0g of crotonic acid and 4.0g of acrylic acid were dissolved in 50ml of toluene, nitrogen was blown and heated to 70°C, and 0.050g of azobisiso Butyronitrile was used as an initiator, stirred and reacted for 4.5 hours, and the solid washed out after cooling, which was a copolymer of c...

Embodiment 2

[0037] Embodiment 2: Fe of the present invention 3 o 4 Structural characterization of @APS@AA-co-CA nanomaterial adsorbent:

[0038] For the present invention Fe 3 o 4 The structural characterization of @APS@AA-co-CA nanomaterial adsorbent includes the following aspects:

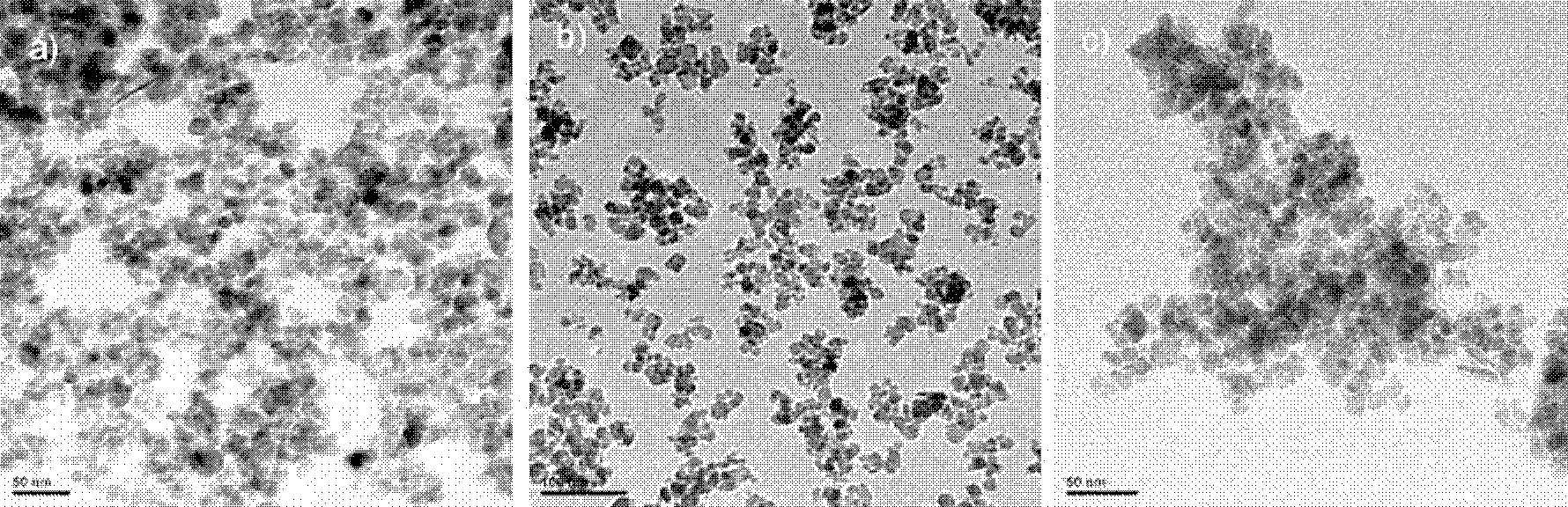

[0039] 1 Morphological observation:

[0040] Fe 3 o 4 The morphology of @APS@AA-co-CA nanomaterial adsorbent is observed, and the results are as follows figure 1 As shown, the set voltage is 120kV and the current is 30mA.

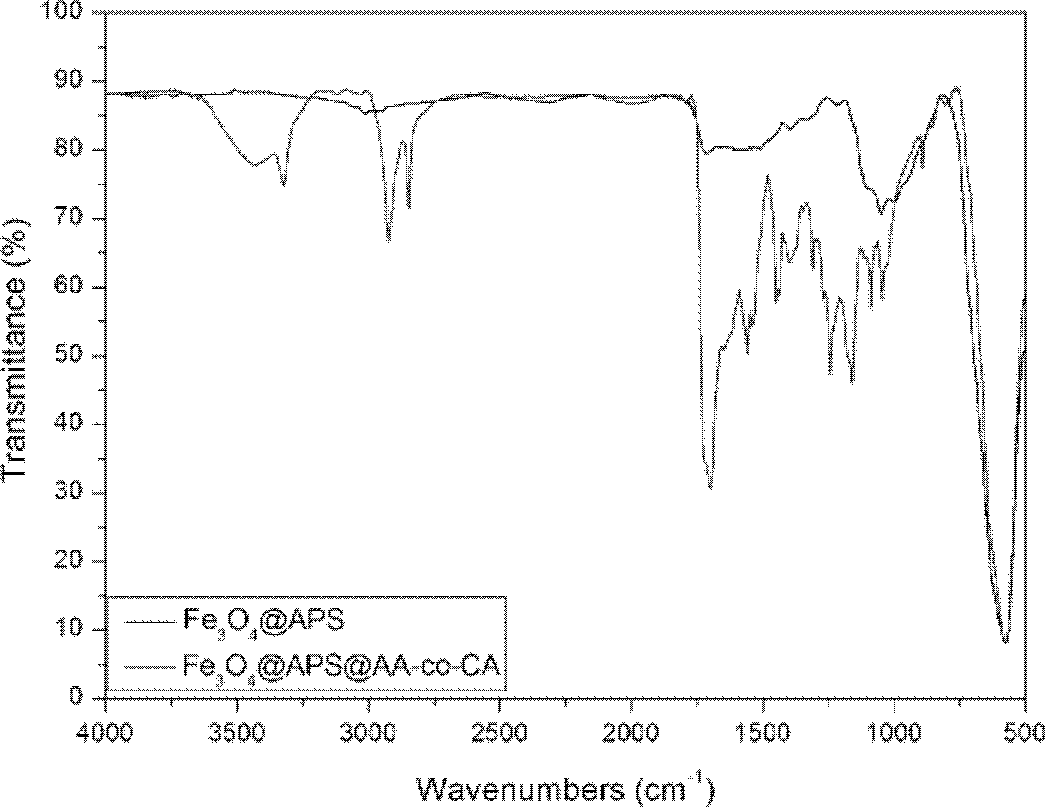

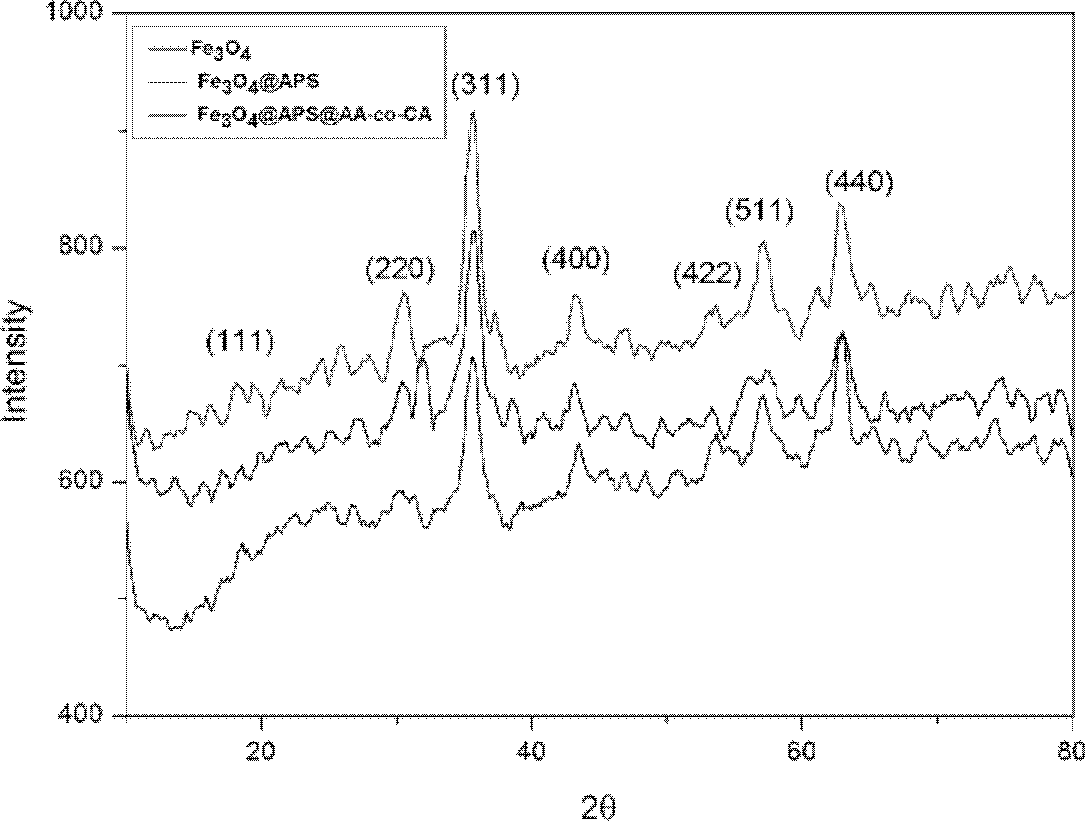

[0041] 2 crystal forms

[0042] X-ray powder diffractometer (Bruker D8 Advance X-ray diffraction analyzer) is used to analyze the crystal form of ferric oxide nanoparticles modified by APS and AA-co-CA, wherein the radiation source is Cu Ka, current 30mA, voltage 40kv, The sample is scanned and analyzed from 10° to 80° at a speed of 0.4° / min, and the results are shown in figure 2 . It can be seen from the figure that after the two kinds of functional groups are modified by X-r...

Embodiment 3

[0047] Embodiment 3: Fe of the present invention 3 o 4 Adsorption capacity test of @APS@AA-co-CA nano-adsorption materials.

[0048] This embodiment is to use Fe of the present invention 3 o 4 @APS@AA-co-CA nanomaterial adsorbent on pollutant Cd 2+ , Zn 2+ , Pb 2+ 、Cu 2+ Adsorption experiments were carried out.

[0049] 1. Adsorption capacity test under different pH conditions

[0050] The experimental method is as follows: configure 100mg.L -1 Cd 2+ , Zn 2+ , Pb 2+ 、Cu 2+ Aqueous solution, adjust pH 1~12 with 0.1M NaOH and hydrochloric acid solution, take 50ml metal ion solution respectively, add 0.050g Fe 3 o 4 @APS@AA-co-CA nanomaterial adsorbent, after stirring for 2 hours, the adsorbent was separated by a magnet, and the solution was tested for the amount of metal ions by a Hewlett-Packard 3510 flame atomic absorption device. The results show that the adsorption effect of the adsorbent is very good under the condition of pH>4. However, if the alkalinity is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com