Preparation and application of multi-phase catalyst for use in synthesis of vanillin

A heterogeneous catalyst and catalyst technology, applied in the preparation of organic compounds, carbon-based compounds, physical/chemical process catalysts, etc., can solve the problems of no industrial application value, difficult post-processing, low catalytic effect, etc., to achieve strong industrial The effect of application value, easy separation and purification, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

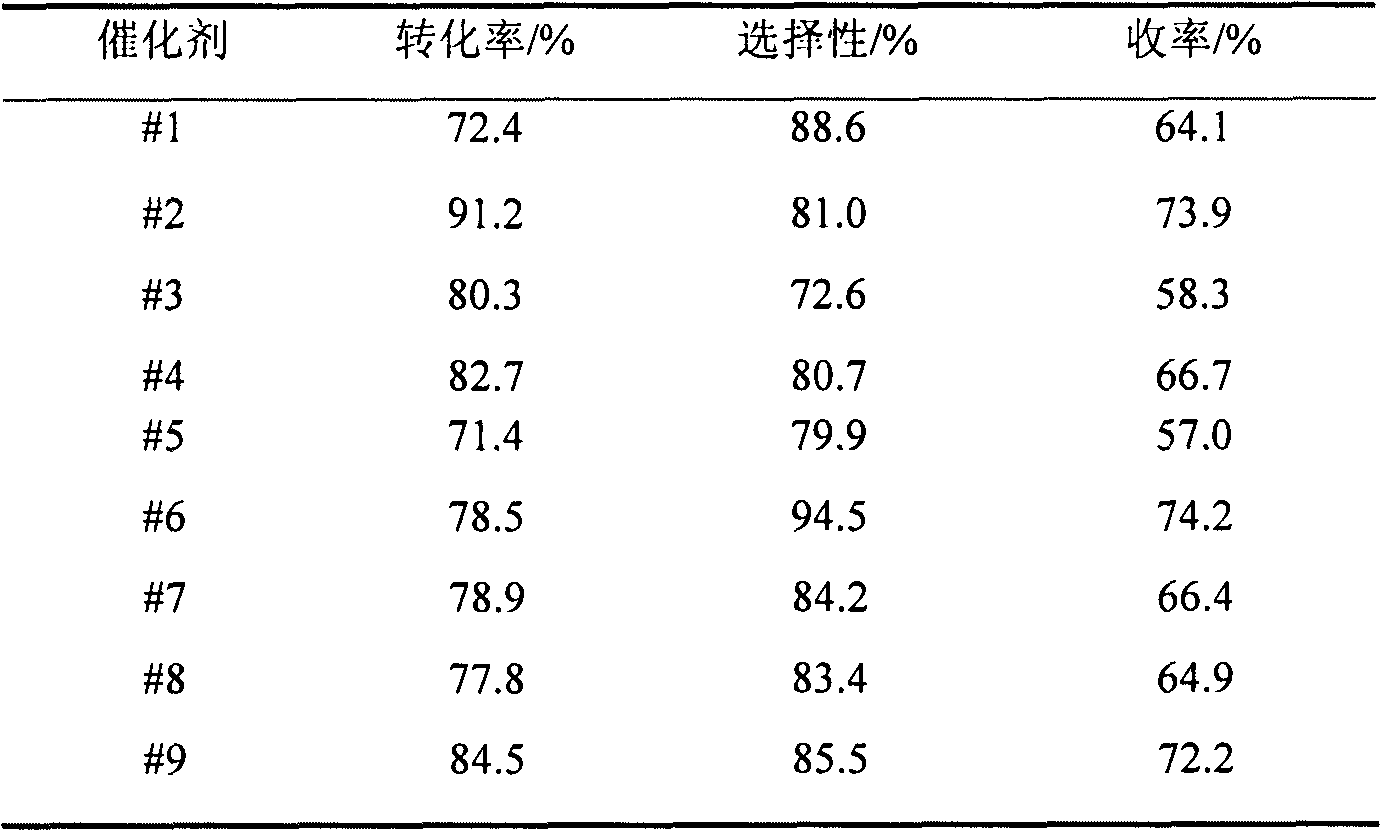

Embodiment 1

[0018] Weigh 1.46gCo(NO 3 ) 2 ·6H 2 O, 1.21gFe(NO 3 ) 3 9H 2 O was prepared into a mixed solution with a certain concentration, and 0.5mol / L NaOH solution was slowly added dropwise to the mixed solution, titrated to pH=9 under vigorous stirring, aged at 60°C for 4 hours, filtered and washed to neutralize the precipitate. Dry at 120°C, bake in a muffle furnace at 400°C for 5 hours, cool and grind to obtain #1 catalyst, and use the implementation plan for evaluation.

Embodiment 2

[0020] Weigh 1.46gCo(NO 3 ) 2 ·6H 2 O, 1.21gFe(NO 3 ) 3 9H 2 O, 0.121gCu(NO 3 ) 2 ·3H 2 O is prepared into a mixed solution with a certain concentration, and 0.25mol / L Na 2 CO 3 The solution was slowly added dropwise to the mixture, titrated to pH=10 under vigorous stirring, aged at 60°C for 4 hours, filtered and washed to neutralize the precipitate. Dry at 120°C, bake in a muffle furnace at 400°C for 5 hours, cool and grind to obtain #2 catalyst, and use the implementation scheme for evaluation.

Embodiment 3

[0022] Weigh 0.876gCo(NO 3 ) 2 ·6H 2 O, 1.21gFe(NO 3 ) 3 9H 2 O, 0.215gZr(NO 3 ) 4 ·5H 2 O was prepared into a mixed solution with a certain concentration, and 0.5 mol / L NaOH solution was slowly added dropwise to the mixed solution, titrated to pH=9 under vigorous stirring, aged at 60°C for 5 hours, filtered and washed to neutralize the precipitate. Drying at 120°C, roasting in a muffle furnace at 400°C for 6 hours, cooling and grinding to obtain catalyst #3, which was evaluated using the implementation plan.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com