Laser-water jet composite micromachining process and device

A microfabrication and water jet technology, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problems of reduced processing quality, crack damage in processing areas, etc., to achieve strong cooling effect, high processing speed, and reduce thermal impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A single crystal silicon wafer with a thickness of 700 μm was processed, and the material properties are shown in Table 1.

[0026] Table 1 Material properties of monocrystalline silicon wafer

[0027] Density [kg / m 3 ]

Thermal conductivity [W / mK]

Heat capacity[J / kgK]

Thermal diffusivity [m 2 / s]

2329

130

700

7.974×10 -5

1687

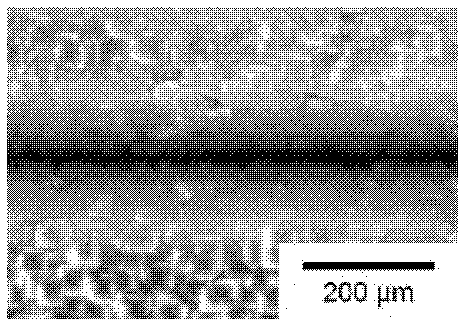

[0028] Processing requirements: the width of the thermal damage zone is less than 20 μm

[0029] According to the material properties, thickness and processing requirements of the processed materials, the laser-water jet composite micromachining process conditions are selected as follows:

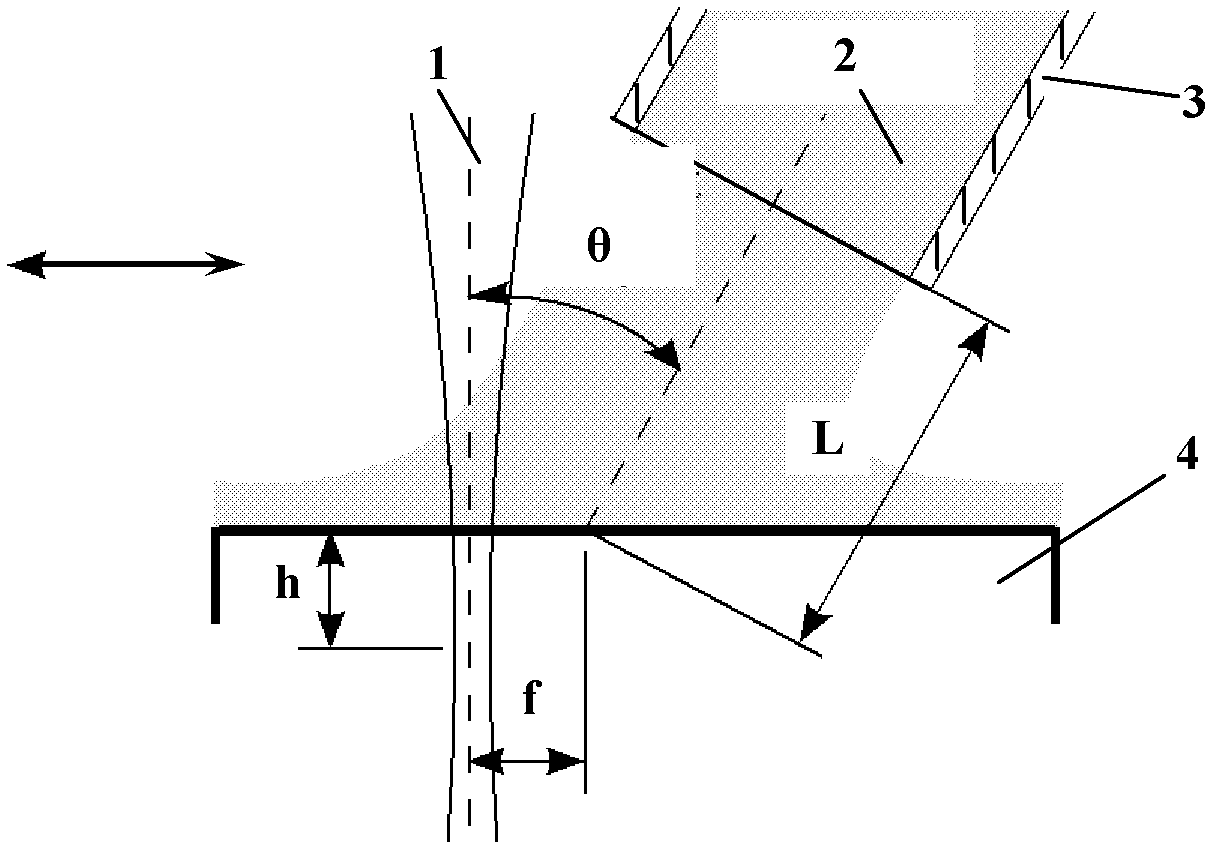

[0030] Water jet offset distance: 0.6mm

[0031] Laser beam focal plane position (fpp): 0mm

[0032] Laser pulse energy: 0.3mJ

[0033] Moving laser pulse overlap factor: 99.3%

[0034] Water jet pressure: 5MPa

[0035] Water jet erosion angle: 30°

[0036] Water ...

Embodiment 2

[0042] A single crystal silicon wafer with a thickness of 700 μm was processed, and the material properties are shown in Table 1.

[0043] Processing requirements: the single-stroke cutting width is greater than 50 μm (the material removal rate is indirectly characterized by the single-stroke cutting width)

[0044] According to the material properties, thickness and processing requirements of the processed materials, the laser-water jet composite micromachining process conditions are selected as follows:

[0045] Water jet offset distance: 0.6mm

[0046] Laser beam focal plane position (fpp): 0mm

[0047] Laser pulse energy: 0.6mJ

[0048] Moving laser pulse overlap factor: 99.9%

[0049] Water jet pressure: 20MPa

[0050] Water jet erosion angle: 60°

[0051] Water jet target distance: 2mm

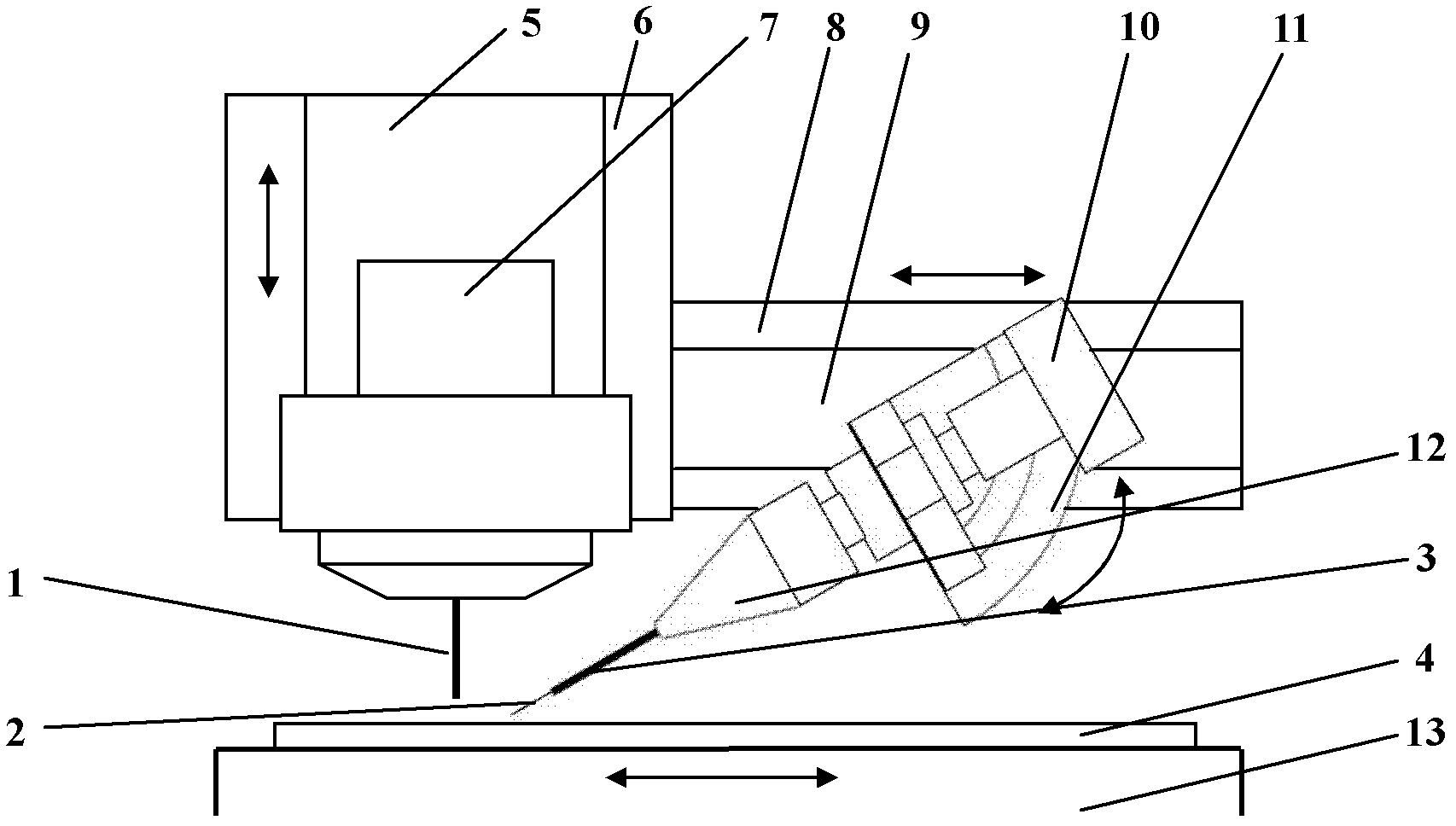

[0052] Workpiece installation: the monocrystalline silicon wafer workpiece 4 is installed on the two-axis mobile numerical control workbench 13, and the single crystal silicon wafe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com