Milky white glass ceramic suitable for all electric melting and preparation process for milky white glass ceramic

A milky white glass and preparation technology, applied in the field of glass processing, to achieve the effect of good stability of material liquid, stable performance, rapid cooling and rapid heating of texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

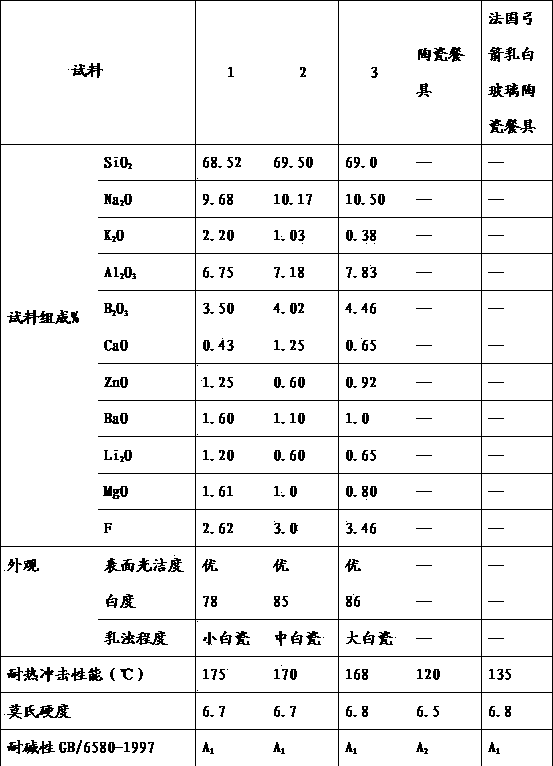

[0027] Weigh the following raw materials in parts by weight: 4.4 parts of alumina powder, 1.8 parts of barium carbonate, 0.15 parts of calcium carbonate, 0.5 parts of fluorite, 4.2 parts of potassium nitrate, 1.4 parts of magnesium oxide, 6.5 parts of borax pentahydrate, 8.3 parts of soda ash, 3.9 parts of sodium fluorosilicate, 7 parts of albite, 2 parts of sodium nitrate, 56.2 parts of quartz sand, 1.1 parts of zinc oxide, 2.8 parts of lithium carbonate, and 0.5 part of dolomite. The batch is mixed evenly, the uniformity is equal to 95%, the moisture content is 3%, and the temperature is equal to 36°C, and then it is put into an electric melting furnace for heating and melting. The maximum temperature of the furnace is 1380°C. , the molten glass flows through the liquid hole-ascending channel (distribution pool)-feeder-feeder basin, the molten glass is formed by pressing at a temperature of 1100°C, then annealed at 585°C for 60 minutes in an annealing kiln, and then sent into...

preparation example 2

[0029] Weigh the following raw materials in parts by weight: 4.2 parts of alumina powder, 1.4 parts of barium carbonate, 0.5 part of calcium carbonate, 1 part of fluorite, 2.2 parts of potassium nitrate, 0.4 part of magnesium oxide, 8.7 parts of borax pentahydrate, 7.6 parts of soda ash, 4.7 parts of sodium fluorosilicate, 17.1 parts of albite, 2.1 parts of sodium nitrate, 56.8 parts of quartz sand, 0.6 part of zinc oxide, 2.6 parts of lithium carbonate, and 0.9 part of dolomite. The batch is mixed evenly, and then put into the electric melting furnace for heating and melting. The maximum temperature of the furnace is 1400℃. Road-feeder basin, the molten glass is centrifugally formed at a temperature of 1200°C, then annealed in an annealing kiln at 590°C for 65 minutes, and sent to a tempering furnace for baking and tempering, and its appearance and physical and chemical properties are evaluated.

preparation example 3

[0031] Weigh the following raw materials in parts by weight: 4.6 parts of alumina powder, 1.3 parts of barium carbonate, 0.4 part of calcium carbonate, 0.6 part of fluorite, 18.2 parts of albite, 0.8 part of potassium nitrate, 0.7 part of magnesium oxide, 9.8 parts of borax pentahydrate 5.9 parts of soda ash, 6 parts of sodium fluorosilicate, 4 parts of sodium nitrate, 55.6 parts of quartz sand, 0.9 parts of zinc oxide, 2.3 parts of lithium carbonate, and 0.6 parts of dolomite. The batch is mixed evenly, the uniformity is equal to 95%, the moisture content is 7%, the temperature is equal to 38°C, and then it is put into the electric melting furnace for heating and melting. The maximum temperature of the furnace is 1520°C. , the molten glass flows through the liquid hole-ascending channel (distribution pool)-feeder-feeder basin, the glass molten glass is centrifugally formed at a temperature of 1280°C, and then annealed in an annealing kiln at 620°C for 70 minutes, and then sent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com