Oil shale rotary kiln dry distillation and circulating fluidized bed combustion process

A circulating fluidized bed and oil shale technology, applied in the petroleum industry, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems of inability to realize power generation, heat supply, temperature cycle change of dry distillation furnace, low resource utilization rate, etc. Achieve the effects of strong adaptability to feed size, short dry distillation time, and high resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

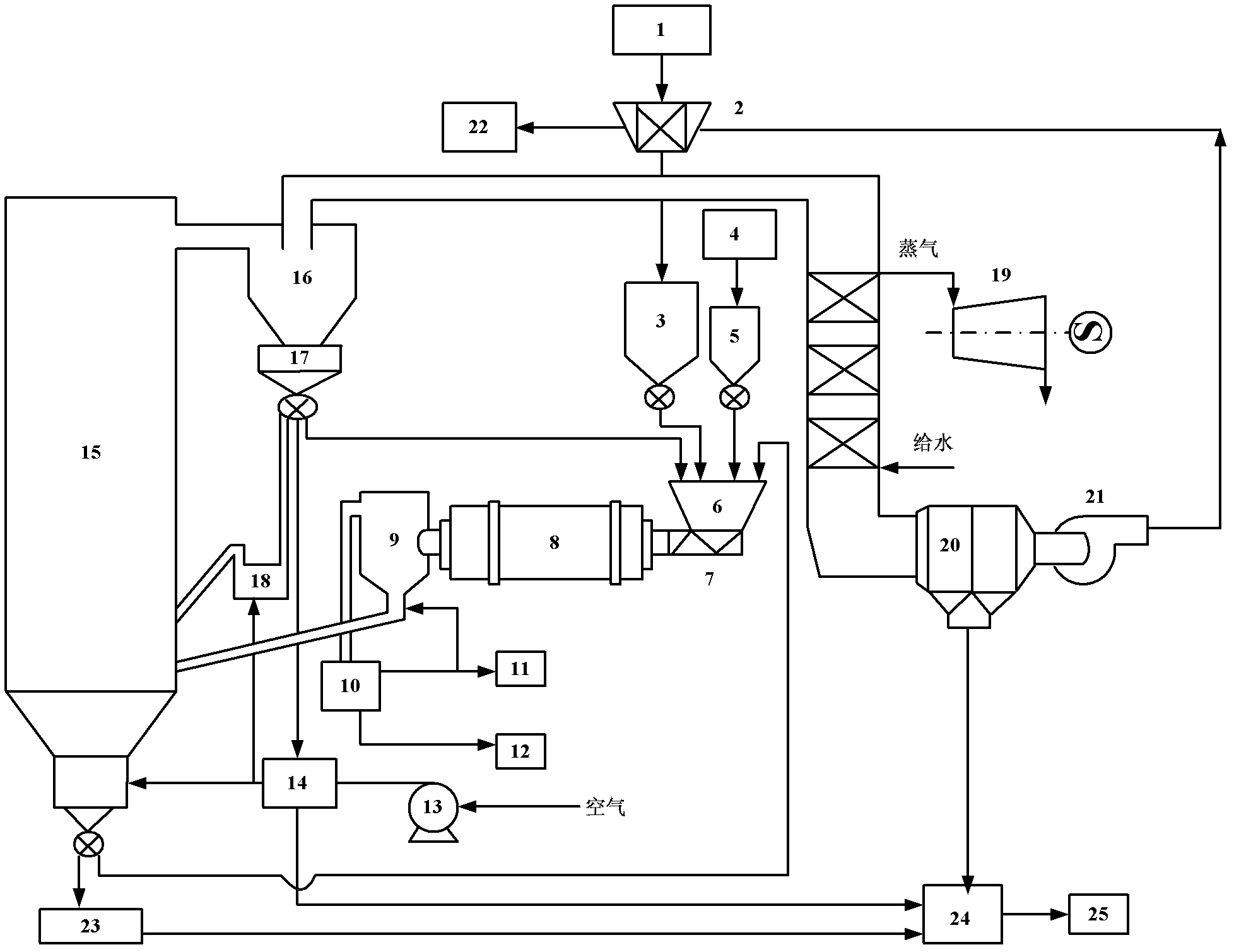

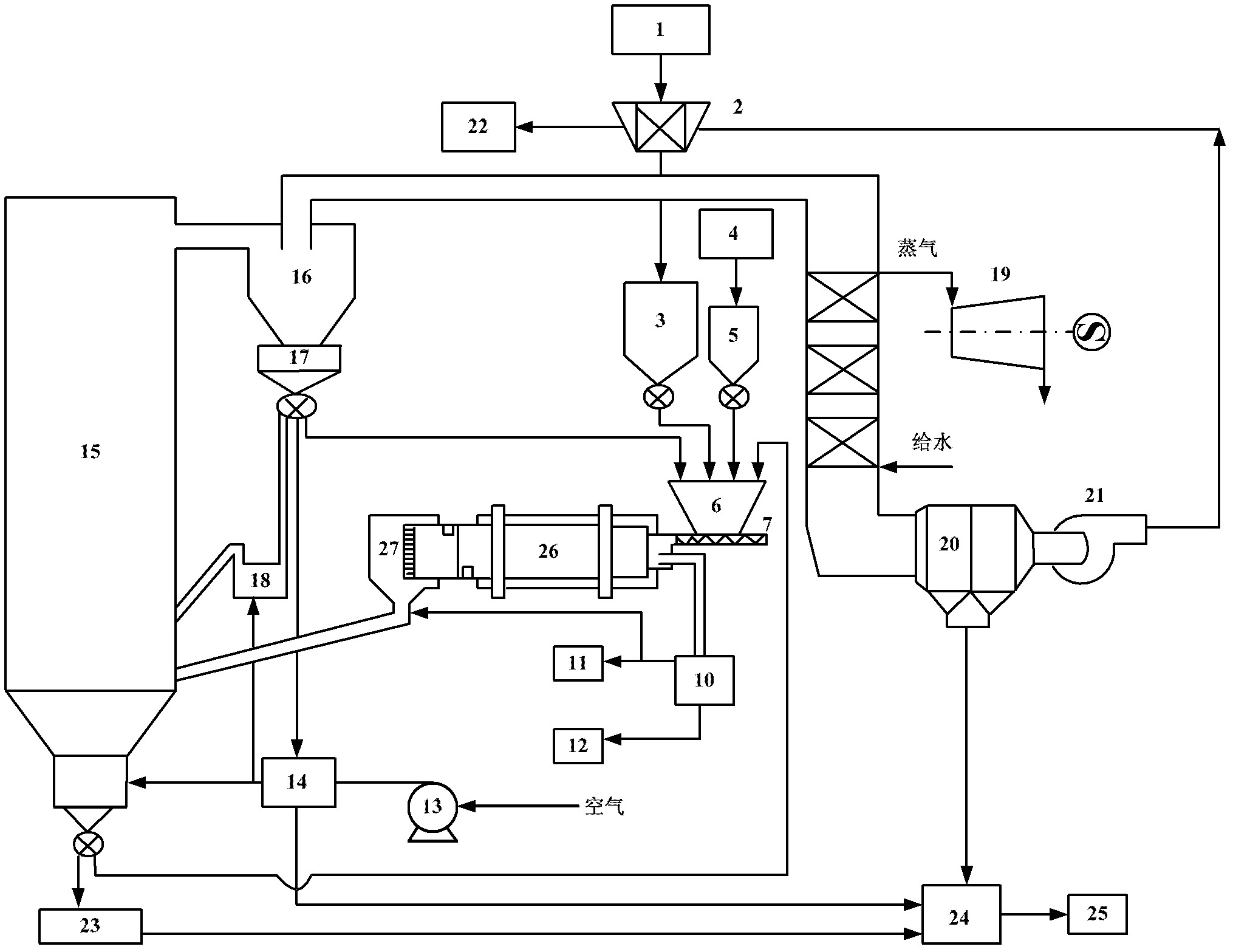

[0023] figure 1 Shown is an oil shale rotary kiln dry distillation and circulating fluidized bed combustion process cis system, that is, a cis oil shale rotary kiln dry distillation and circulating fluidized bed combustion system.

[0024] Such as figure 1 As shown, the oil shale ore 1 is crushed into 0-15mm particles by a drying crusher 2, and then preheated and dried by high temperature flue gas, and then sent to the oil shale feed hopper 3 through a belt, and the oil shale is removed by a star-shaped rotary valve The particles are sent to the closed mixer 6, where the oil shale particles and the shale ash collection tank 17 from the bottom of the circulating fluidized bed cyclone separator 16 are circulating ash with a temperature of 750-850℃ and part of the circulating fluidized bed boiler Bottom ash is mixed, and the weight mixing ratio is shale ash: oil shale is 2~3:1. In addition, organic matter such as coal, waste rubber or plastic or inorganic matter such as limestone des...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com