Jatropha curcas seed protein hydrolysate-derived antibacterial peptide and preparation method thereof

A technology of protein hydrolyzate and jatropha seeds, applied in the field of preparation and purification of bioactive peptides, can solve the problems of high cost of chemical synthesis, difficult industrialization, weak anti-virus ability, etc., to reduce environmental pollution and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

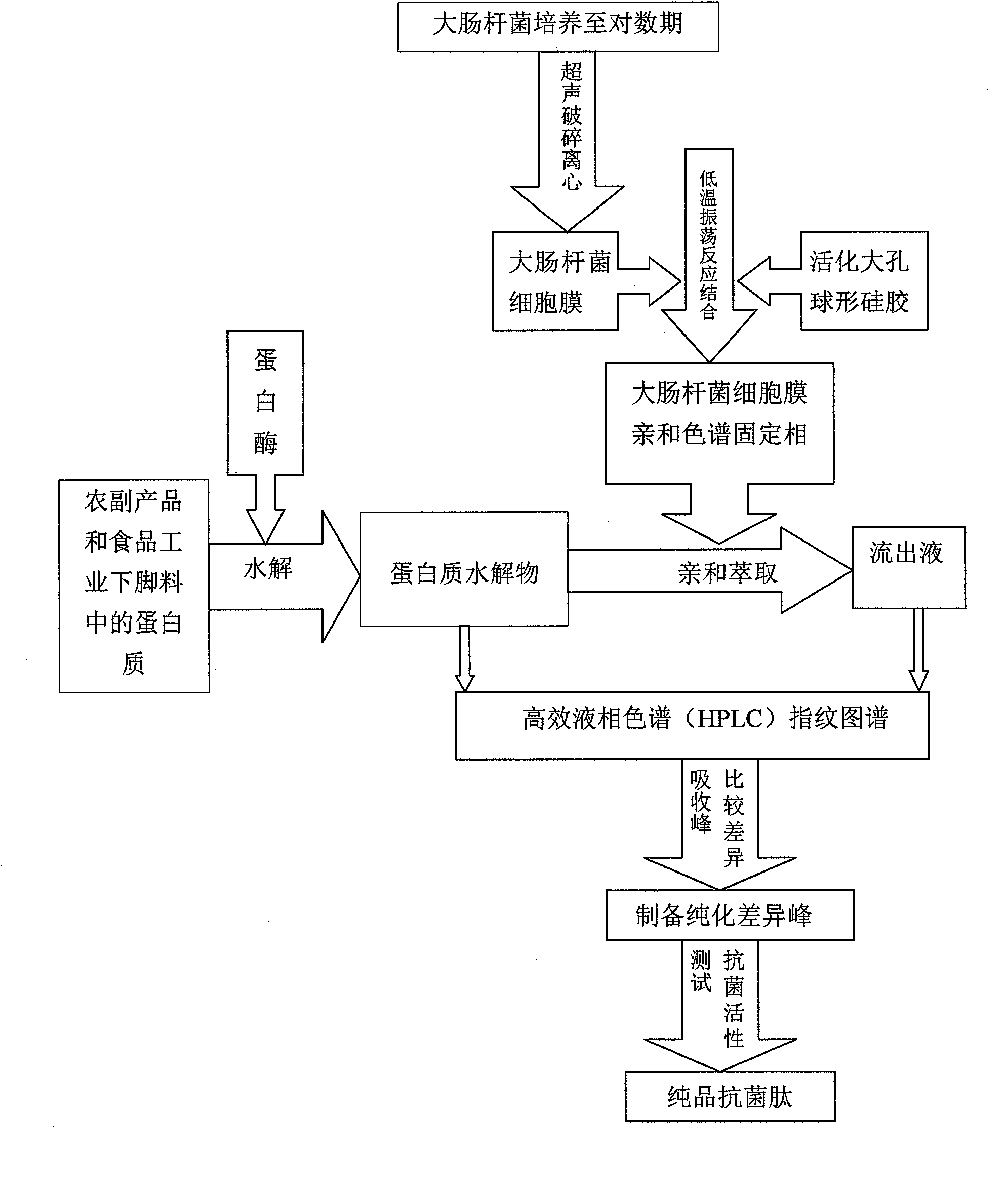

Method used

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 affinity cell membrane stationary phase

[0023] Centrifuge 500ml of Escherichia coli cultured to the logarithmic phase at 4000r / min for 15min to obtain the bacteria. The bacteria were washed 10 times with 25ml of Tris-EDTA buffer (pH7.4) to remove the medium residue. The cleaned bacterial cells were redissolved with Tris-EDTA buffer, frozen in a -30°C refrigerator for 4 hours, taken out and thawed in a 37°C water bath, and then centrifuged at 3000r / min for 15min after repeated freezing and thawing 5 times. The frozen-thawed bacteria were subjected to cell lysis treatment at 600W ultrasonic power. The ultrasonic wave was irradiated for 4s each time, with an interval of 4s, and a total time of 60min. The pellet was obtained by low-speed centrifugation, which was the cell membrane of Escherichia coli. Put 10ml of the suspension prepared by reconstitution of the obtained cell membrane into a centrifuge tube, then add 0.5g (3-7μm) of activate...

Embodiment 2

[0024] The preparation of embodiment 2 protein antibacterial hydrolyzate

[0025] Taking Jatropha curcas seed meal protein as an example, take 10g of protein sample with a purity of 92.26%, add 100mL of deionized water, and hydrolyze with different proteases. The optimal conditions for protease hydrolysis are shown in Table 1. After the protein solution is hydrolyzed by different proteases into different degrees of hydrolysis (7%, 9%, 11%, 13%, 15% and 17%), adjust the pH of the turbid solution to 7.5 at 45°C, and inactivate the enzyme in a 100°C water bath 10min, then centrifuged at 4000r / min for 15min, obtained the supernatant, freeze-dried, reconstituted into 1mg / ml sample solution, and tested the antibacterial ability separately to find out the component with the strongest antibacterial ability, and cooled to dry. name this sample

[0026] Named as Fh13. Table 1 Optimum Action Conditions for Protease

[0027]

Embodiment 3

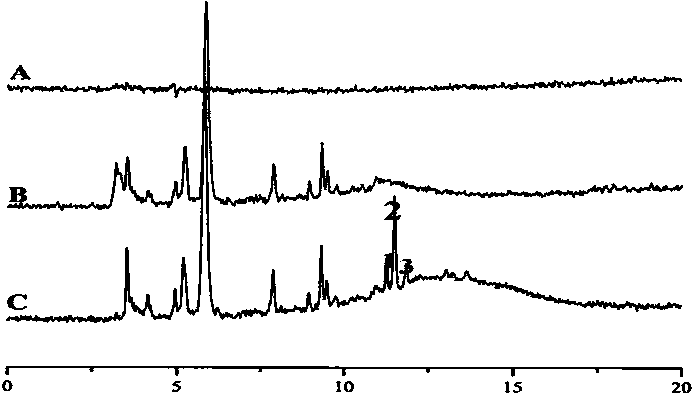

[0028] Example 3 Affinity Extraction Combined with High Performance Liquid Chromatography and Mass Spectrometry for Accurate and Rapid Discovery and Identification of Antimicrobial Peptides

[0029] The affinity stationary phase in Example 1 and the Fh13 in Example 2 were placed in a 10 ml centrifuge tube, and after shaking and binding at 37° C. for 1 hour, the supernatant obtained was centrifuged. The precipitate was washed 7 times with buffer solution, and the washing solution and supernatant were combined, cooled to dryness and named as Fh13-1. Redissolve Fh13 and Fh13-1, and use high performance liquid chromatography-mass spectrometry to detect their fingerprints and analyze differential peaks (see attached image 3 No. 1, 2 and 3 peaks in ), prepare differential peaks and carry out antibacterial ability test. Under this condition, a protein hydrolyzate-derived antimicrobial peptide was rapidly discovered and prepared. The series of this peptide is CAILTHKR, and its minim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com