Method for preparing graphene powder by electrochemistry

A graphene powder, electrochemical technology, applied in the direction of electrolysis process, electrolysis components, etc., to achieve the effect of reducing pollution, low cost, simple and fast preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

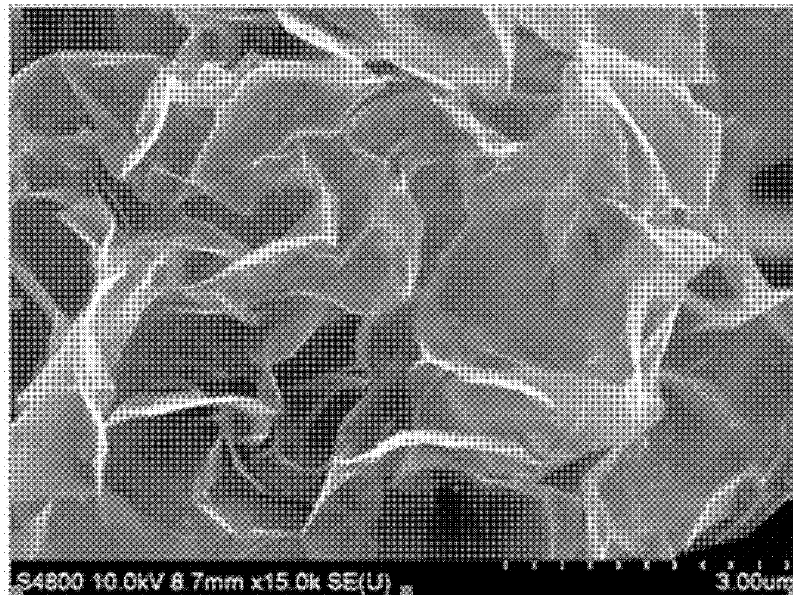

Image

Examples

Embodiment 1

[0036] Example 1, preparation of positive electrode: Highly oriented pyrolytic graphite was glued on a tungsten wire with a diameter of 0.1 mm and a length of 50 cm, and then wound on a silver sheet with a size of 5 cm×8 cm and a pitch of 2.5 cm. Negative electrode: a platinum cylindrical electrode with a diameter of 2 mm is used. In a 250mL beaker, dissolve 4g of 98% concentrated sulfuric acid in 100mL of deionized water, then add dropwise 30% KOH solution to adjust the pH of the solution to 0.50, and place the above two electrodes in parallel with a distance of 1cm. Connected as an electrochemical device with copper wires. First apply a voltage of 1.0V on the positive electrode for 10 minutes, then raise the voltage to 3V for 1 minute, small bubbles begin to appear on the surface of the graphite and platinum electrodes, and the edges of the graphite begin to dissolve. After 5 seconds, the whole and the end begin to expand, and continue to raise the voltage to 25V, the graph...

Embodiment 2

[0037] Example 2, preparation of positive electrode: stick highly oriented pyrolytic graphite on a tungsten wire with a diameter of 0.5 mm and a length of 10 cm, and then wind it on a silver sheet with a size of 1 cm×3 cm and a pitch of 0.7 cm. Negative electrode: a platinum cylindrical electrode with a diameter of 5mm is used. In a 250mL beaker, dissolve 4g of 98% concentrated sulfuric acid in 100mL of deionized water, then add dropwise 30% KOH solution to adjust the pH of the solution to 7.00±0.19, place the above two electrodes in parallel with a distance of 6cm . Connected as an electrochemical device with copper wires. First apply a voltage of 2.5V on the positive electrode for 1min, then increase the voltage to 10V, and continue for 0.5min, bubbles will appear continuously on the surface of the graphite and platinum electrodes, then increase the voltage to 20V, the graphite begins to dissolve and decompose into small pieces, and the solution begins It turns brownish ye...

Embodiment 3

[0038] Example 3, preparing the positive electrode: the expanded graphite is installed in a plastic tube with a 0.1 μm sieve opening with a laser on the tube wall with an inner diameter of 10 mm, the tube is wrapped by a 350 mesh screen, and a metal Ni electrode with an outer diameter of 1 mm is inserted Which made the positive electrode. Negative electrode: a platinum cylindrical electrode with a diameter of 5 mm is used. In a 250mL beaker, dissolve 4g of 98% concentrated sulfuric acid in 100mL of deionized water, then add dropwise 30% KOH solution to adjust the pH of the solution to 10.00±0.05. Place the above two electrodes in parallel with a distance of 5cm. Connected as an electrochemical device with copper wires. First apply a voltage of 0.1V on the positive electrode for 10 minutes, then increase the voltage to 2.5V for 5 minutes, continuous bubbles appear on the surface of the graphite and platinum electrodes, then increase the voltage to 25V, the graphite begins to d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com