Filament oil agent for poly-p-phenylene telephthalamide

A technology of poly(p-phenylene terephthalamide) and filament oil, which can be used in fiber type, fiber treatment, textile and paper making, etc., can solve the problems of oil heat resistance, smoothness and poor adaptability, etc. Achieve the effect of improving post-processing, reducing taring and light color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

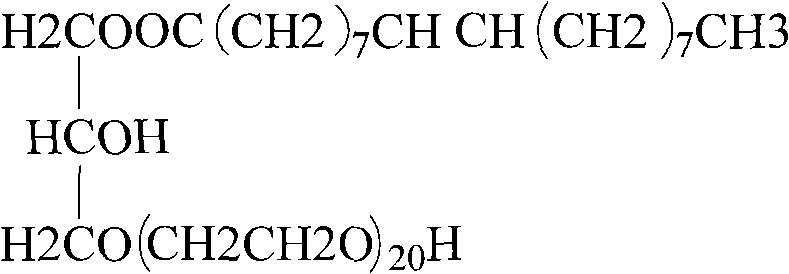

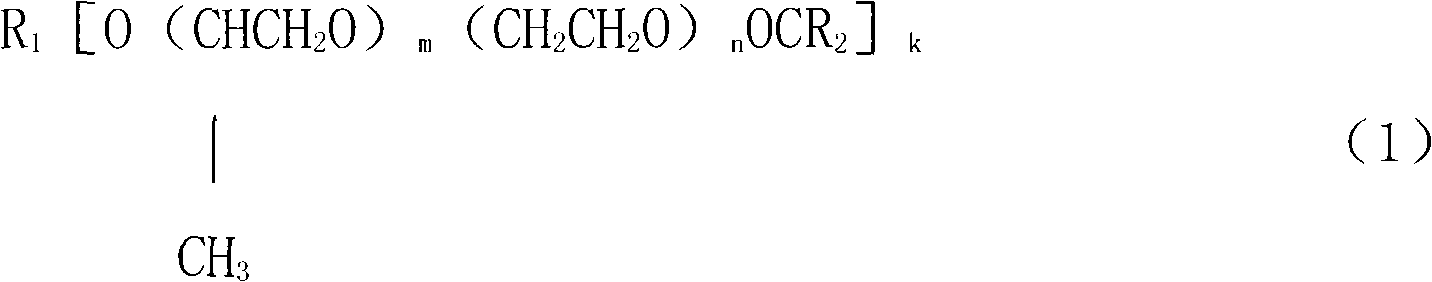

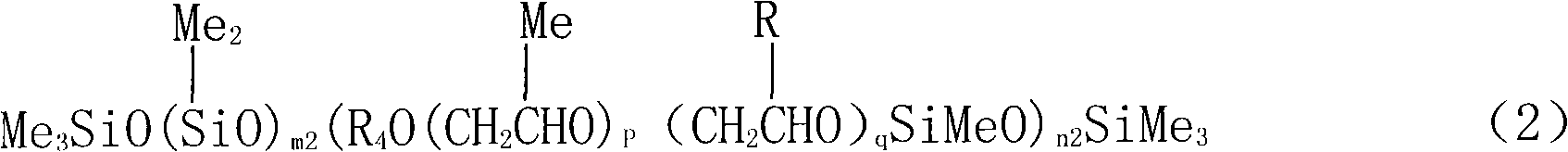

[0032]15 grams of trimethylolpropane tricaprylate, 25 grams of polyoxyethylene (polyoxyethylene mole number is 10) glycerol monooleate, 30 grams of n-octadecanol ethylene oxide propylene oxide random Copolyether n-butyrate (m=20, n=15, k=1), 8 grams of dodecyl polyoxyethylene (polyoxyethylene molarity is 3) phosphate potassium salt four monomers are added to a 150 ml beaker , stirred at 35-40°C for 30 minutes, then added 15 grams of oleyl alcohol (cis-9-octadecenyl alcohol) oleic acid (cis-9-+ octaenoic acid) ester, 5 grams of adipate diiso Octanol ester, 2 g polyether modified silicone oil (R 4 for C 4 methylene, m2=10, n2=10, p=40, q=60, r=4), stirred at 35-40° C. for another 30 minutes, and then filtered through a 100-mesh filter.

Embodiment 2

[0034] 40 grams of trimethylolpropane tricaprylate, 15 grams of polyoxyethylene (polyoxyethylene molarity is 10) glycerol dioleate, 25 grams of n-octadecyl alcohol ethylene oxide propylene oxide random Copolyether n-butyrate (m=20, n=15, k=1), 5 grams of dodecyl polyoxyethylene (polyoxyethylene molarity is 3) phosphate potassium salt four monomers are added to a 150 ml beaker , stirred at 30-40°C for 30 minutes, then added 10 grams of oleyl alcohol (cis-9-octadecenyl alcohol) oleic acid (cis-9-+ octaenoic acid) ester, 3 grams of adipate diiso Octanol ester, 2 g polyether modified silicone oil (R 4 for C 4 methylene, m2=10, n2=10, p=40, q=60, r=4), stirred at 35-40° C. for another 30 minutes, and then filtered through a 100-mesh filter.

Embodiment 3

[0036] With 30 grams of trimethylolpropane coconut oleate, 15 grams of polyoxyethylene (polyoxyethylene molarity is 20) glycerol monolaurate, 20 grams of n-octanol ethylene oxide propylene oxide random copolymerization Ether n-butyrate (m=20, n=10, k=1), 10 grams of dodecyl polyoxyethylene (polyoxyethylene molarity is 5) phosphate potassium salt four monomers are added in a 150 ml beaker , stirred at 30-40°C for 30 minutes, then added 20 grams of lauryl adipate, 4 grams of diisooctyl sebacate, and 1 gram of polyether modified silicone oil (R 4 for C 2 methylene, m2=10, n2=20, p=40, q=60, r=4), stirred at 35-40° C. for another 30 minutes, and then filtered through a 100-mesh filter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com