Detecting method of ammonia and hydrogen sulfide in wet ammonia-containing acidic gas

A technology containing amino acid and detection method, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of analysis system corrosion and blockage, complex analysis process, easy corrosion and blockage of analysis system, etc., to reduce corrosion, analyze Fast, guaranteed long-term stable operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

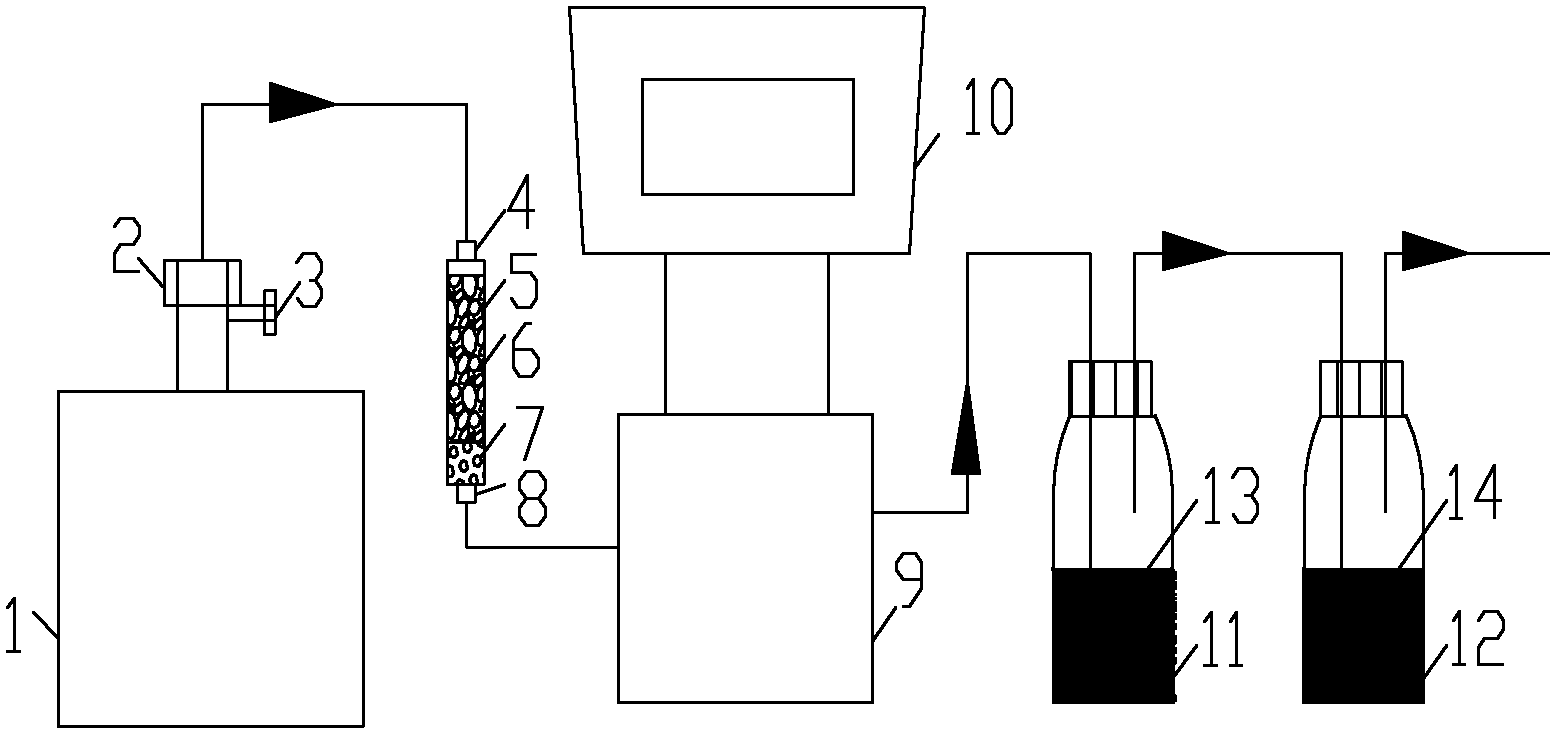

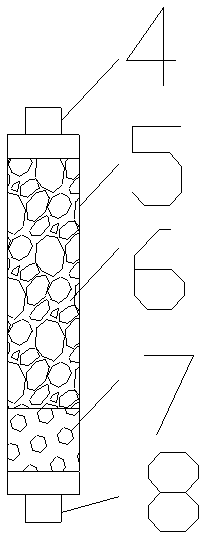

[0055] figure 1 It is a schematic diagram of the analysis process of ammonia and hydrogen sulfide in wet acid-containing gas. Calcium carbide and molecular sieves are packed in sections with an inner diameter of 30mm and a length of 180mm in stainless steel tube 5, and the height ratio of the two is 4:1. The gas outlet 8 of the stainless steel tube is connected to the sample inlet of the gas chromatograph 9 through a pipeline, and the gas inlet 4 of the stainless steel tube is connected to a nitrogen bottle filled with a purity of 99.99% through a pipeline, and nitrogen is purged for standby.

[0056] After the sampling gas bag 1 is replaced three times with hydrogen gas, it is filled with hydrogen gas which is about 1 / 3 of the volume of the gas bag, and then the gas sample is diluted with the sampling gas bag filled with hydrogen gas. Connect the sampling gas bag 1 filled with the gas sample to be tested diluted by hydrogen with the gas inlet 4 of the stainless steel tube thr...

Embodiment 2

[0059] Calcium carbide and zeolite are packed in sections into a stainless steel tube 5 with an inner diameter of 25 mm and a length of 250 mm, and the height ratio of the two is 5:1. The gas outlet 8 of the stainless steel tube is connected to the sample inlet of the gas chromatograph 9 through a pipeline, and the gas inlet 4 of the stainless steel tube is connected to a nitrogen bottle filled with a purity of 99.99% through a pipeline, and nitrogen is purged for standby.

[0060] After the sampling gas bag 1 is replaced with hydrogen three times, it is filled with hydrogen gas which is about 1 / 4 of the volume of the gas bag, and then the gas sample is diluted with the sampling gas bag filled with hydrogen gas. Connect the sampling gas bag 1 filled with the gas sample to be tested diluted by hydrogen with the gas inlet 4 of the stainless steel tube through the pipeline, open the valve 3 at the mouth of the sampling gas bag, and the gas sample to be tested diluted by hydrogen e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com