High-temperature-resistant far infrared radiation coating

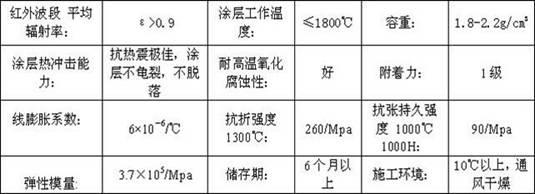

A far-infrared radiation and high-temperature-resistant technology, which is applied in the field of high-temperature-resistant far-infrared radiation coatings, can solve the problems that it is difficult for materials to meet the requirements of firm structure, high thermal insulation and high reflectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

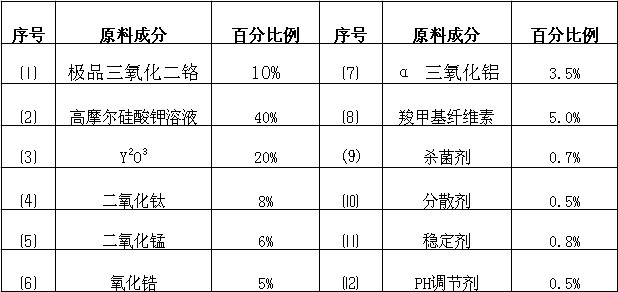

[0007] Firstly grind (1) the top-quality chromium trioxide powder into a fine powder of more than 500 meshes, (2) high-mole potassium silicate solution is stirred and matured at a high speed, and the rotation speed of the mixer should reach more than 3500 / min. Stir for more than 30 minutes, and the stirred (2) high-mole silicon Potassium acid solution is left to mature for more than 2 hours;

[0008] Add the matured high-molar potassium silicate solution gradually under the stirring of 3000 / min, and add the ground super-grade chromium trioxide, Y 2 o 3 , manganese dioxide, zirconia, α-alumina, and titanium dioxide materials, after stirring for 30 minutes, add carboxymethyl cellulose, bactericide, dispersant, stabilizer, pH regulator, and then stir at high speed after adding, the number of revolutions of the mixer To achieve more than 4500 / min, it is enough to stir for 30 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com