Flame retardant polyurethane spray coating foamed plastic

A technology of foamed plastics and polyurethane, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of failing to pass the C-level test, not belonging to foamed plastics, and great practical significance. It is stable to heat and ultraviolet rays, and is not easy to be toxic Good effect of gas and corrosive gas, flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121] The combined white material is configured according to the mass parts:

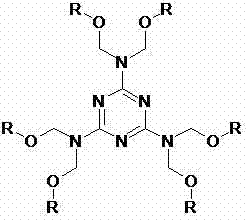

[0122] Amino resin with polyhydroxy structure 75 parts

[0123] Trihydroxyphosphate 5 parts

[0124] Ammonium polyphosphate (APP) superfine powder 20 parts

[0125] Glycerin 10 parts

[0126] Silicone oil AK8805 3 parts

[0127] 0.6 parts of water

[0128] N, N, N, N, N-pentamethyldiethylenetriamine (PC-5) catalyst 0.3 parts

[0129] Dimethylcyclohexylamine (PC-8) catalyst 1 part

[0130] 33Wt.% dipropylene glycol solution of triethylenediamine (A33) catalyst 2 parts

[0131] Organotin T-12 catalyst 0.2 parts

[0132] Hexahydrotriazine (PC-41) catalyst 3 parts

[0133] Fatty alcohol polyoxyethylene ether dispersant 11 parts

[0134] Tetrakis(2-chloroethyl)diethylene ether diphosphate (FR-505) 35 parts

[0135] Foaming agent 141B 30 parts.

[0136] The mass ratio of combined white material and isocyanate (PAPI) is 1:1.1, and airless spraying is carried out with a spray gun. The thickness ...

Embodiment 2

[0139] The combined white material is configured according to the mass parts:

[0140] Amino resin with polyhydroxy structure 65 parts

[0141] Trihydroxyphosphate 15 parts

[0142] Ammonium polyphosphate (APP) superfine powder 15 parts

[0143] Glycerin 15 parts

[0144] Silicone oil AK8805 2.5 parts

[0145] 0.7 parts of water

[0146] N, N, N, N, N-pentamethyldiethylenetriamine (PC-5) catalyst 0.25 parts

[0147] Dimethylcyclohexylamine (PC-8) catalyst 0.8 parts

[0148] 33Wt.% dipropylene glycol solution of triethylenediamine (A33) catalyst 1.9 parts

[0149] Organotin T-12 catalyst 0.17 parts

[0150] Hexahydrotriazine (PC-41) catalyst 3.2 parts

[0151] Fatty alcohol polyoxyethylene ether dispersant 15 parts

[0152] Tetrakis(2-chloroethyl)diethylene ether diphosphate (FR-505) 30 parts

[0153] Foaming agent 141B 38 parts

[0154] The mass ratio of combined white material and isocyanate (PAPI) is 1:1, and airless spraying is carried out with a spray gun. The t...

Embodiment 3

[0157] The combined white material is configured according to the mass parts:

[0158] Amino resin with polyhydroxy structure 70 parts

[0159] Trihydroxyphosphate 10 parts

[0160] Ammonium polyphosphate (APP) superfine powder 8 parts

[0161] Glycerin 13 parts

[0162] Silicone oil AK8805 2.8 parts

[0163] 0.8 parts of water

[0164] N, N, N, N, N-pentamethyldiethylenetriamine (PC-5) catalyst 0.27 parts

[0165] Dimethylcyclohexylamine (PC-8) catalyst 0.9 parts

[0166] 33 Wt.% triethylenediamine dipropylene glycol solution (A33) catalyst 1.8 parts

[0167]Organotin T-12 catalyst 0.15 parts

[0168] Hexahydrotriazine (PC-41) catalyst 3.5 parts

[0169] Fatty alcohol polyoxyethylene ether dispersant 13 parts

[0170] Tetrakis(2-chloroethyl)diethylene ether diphosphate (FR-505) 25 parts

[0171] Foaming agent 141B 34 parts.

[0172] The mass ratio of combined white material and isocyanate (PAPI) is 1:1.2, and airless spraying is carried out with a spray gun. The th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com