Method for preparing hollow fiber molecular sieve membranes in batches

A batch, molecular sieve technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high operation requirements, high mechanization difficulty, low molecular sieve membrane flux, etc. Yield and reduction of tediousness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

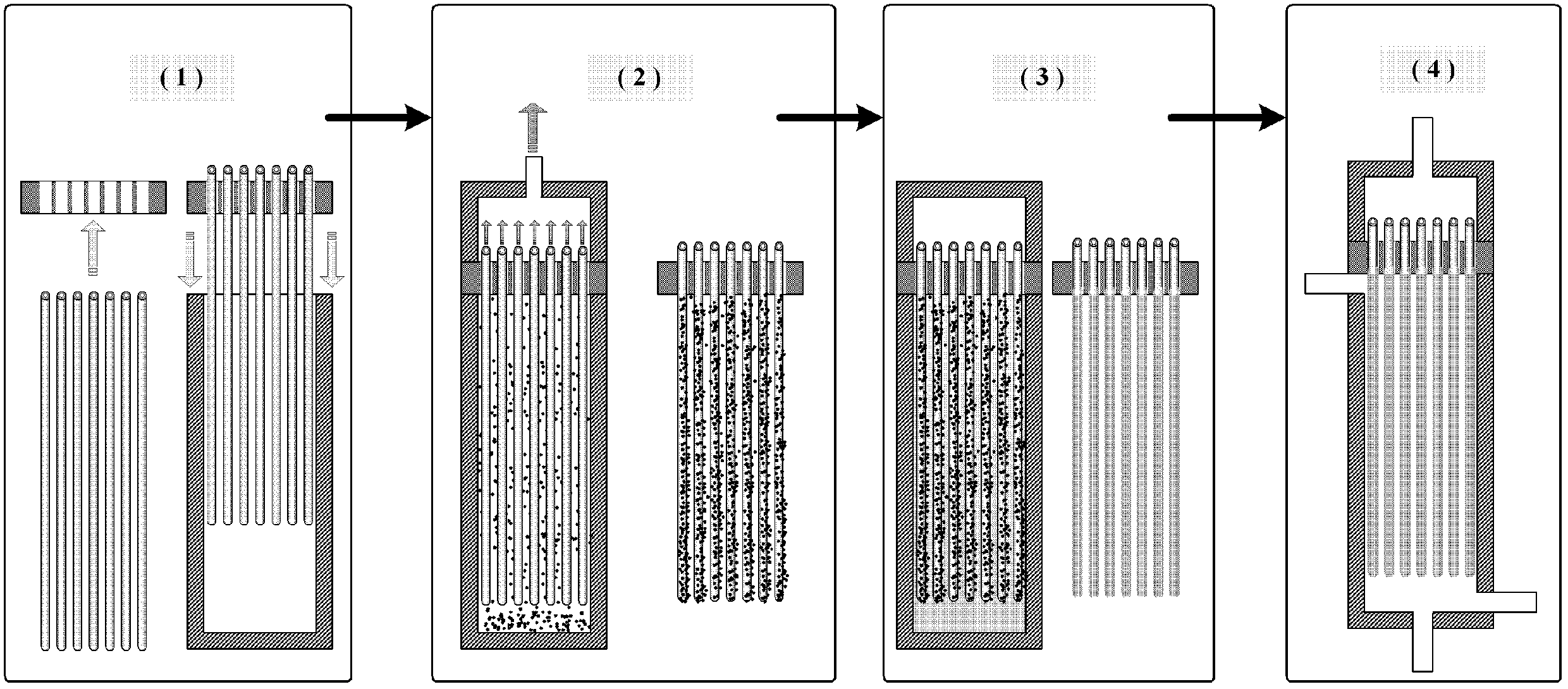

[0029] Example 1 Preparation of Hollow Fiber NaA Molecular Sieve Membrane Bundle Assembly by Dipping and Coating Seed Crystals

[0030] Step 1 Prefabrication of hollow fiber bundles

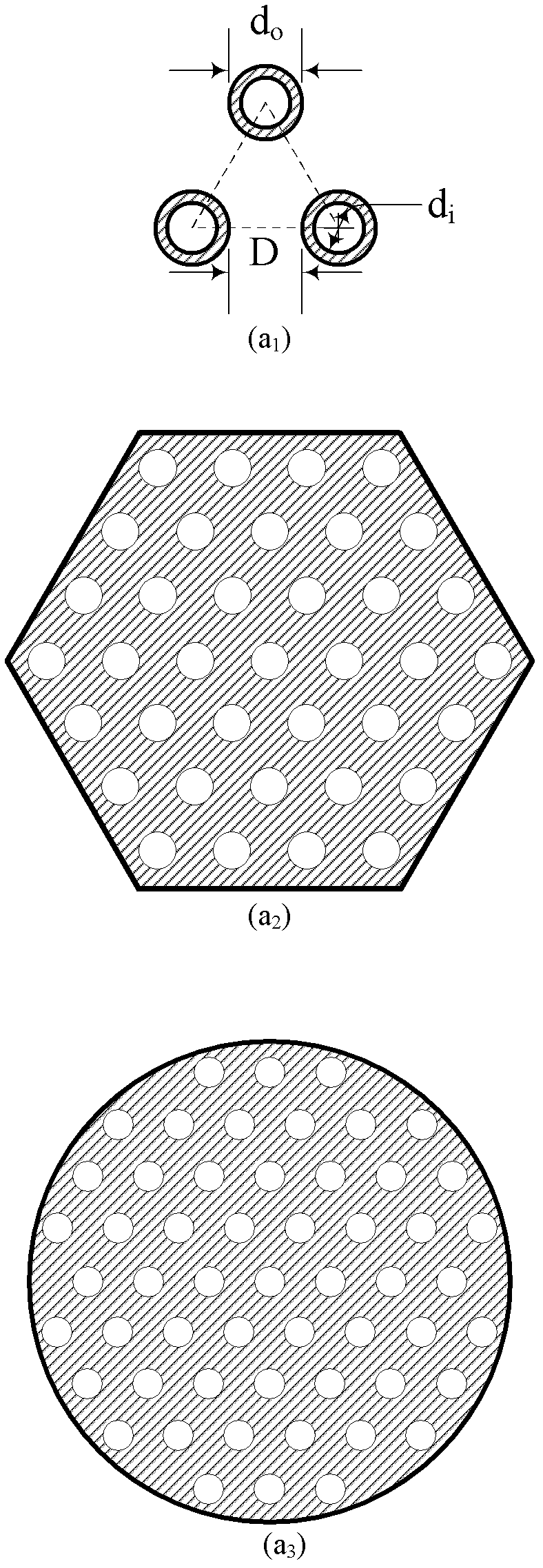

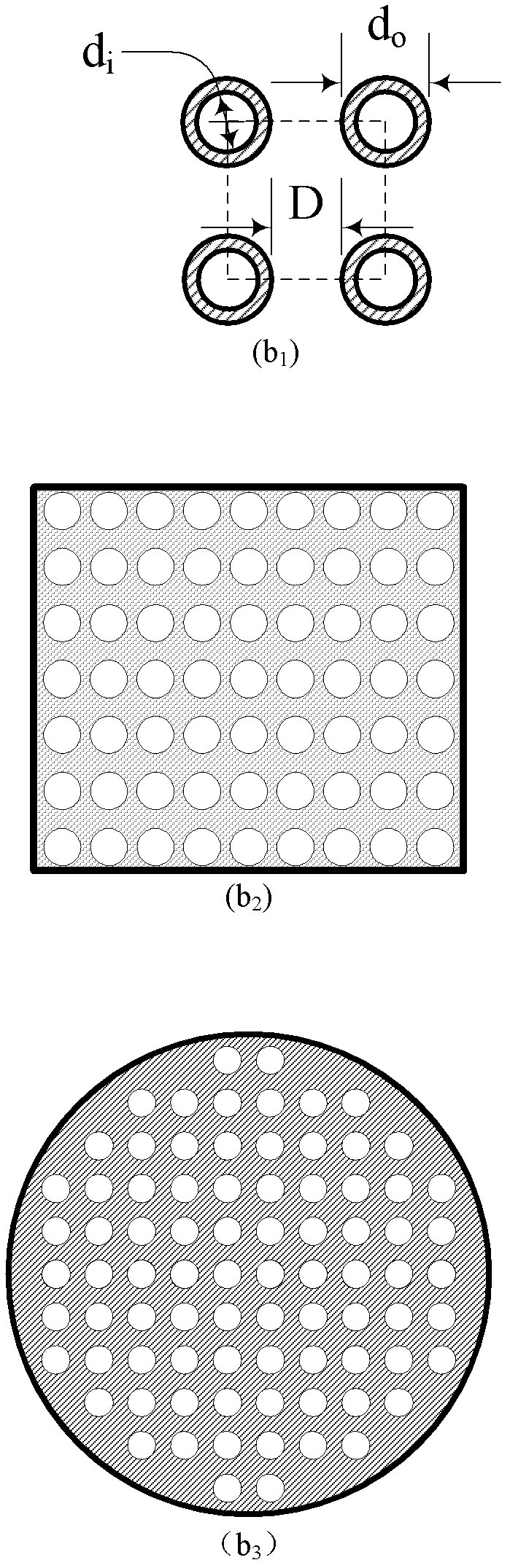

[0031] α-Al 2 o 3 The surface of the hollow fiber support body is polished and polished with SiC sandpaper to make the surface pore diameter uniform, and the rectangular arrangement unit is pre-arranged into clusters (perfect rows). Fiber spacing D is 1d o , the cross-sectional fiber arrangement density is 148,000 / m 2 , the hollow fiber support body is fixed by a prefabricated orifice plate, arranged in a circular shape between the clusters, 80 pieces per cluster; the outer diameter of the hollow fiber ceramic support is d o 2mm, inner diameter d i It is 1mm, the length is 0.25m, the average pore diameter is 0.8μm, and the porosity is 50%.

[0032] Step 2 Seed coating of hollow fiber bundles

[0033] The prefabricated ceramic hollow fiber support is bundled and dried at 120°C, then immerse...

Embodiment 2

[0038] Example 2 Preparation of Hollow Fiber NaA Molecular Sieve Membrane Bundle Assembly by Coating Seed Crystals with Vacuum Suction

[0039] Step 1 Prefabrication of hollow fiber bundles Same as step 1 of embodiment 1

[0040] The hollow fiber supports are pre-regularly arranged into bundles with triangles as their arrangement units. Fiber spacing D is 0.5d o , the cross-sectional fiber arrangement density is 475,000 / m 2 , the hollow fiber support body is fixed by the prefabricated orifice plate, arranged in a circular shape, 95 pieces / cluster; the outer diameter of the hollow fiber ceramic support is d o 1.8mm, inner diameter d i It is 0.9mm, the length is 0.4m, the average pore diameter is 0.6μm, and the porosity is 37%.

[0041] Step 2 Seed coating of hollow fiber bundles

[0042] Saturate the prefabricated fibers with water, and then immerse them in the prepared seed crystal suspension (the seed crystals are crushed by ball milling, the particle size is about 0.3 μ...

Embodiment 3

[0047] Example 3 Preparation of Hollow Fiber NaA Molecular Sieve Membrane Bundle Module by Ultrasonic Coating Seed Crystal

[0048] Step 1 Prefabrication of hollow fiber bundles

[0049] As described in step 1 of embodiment 2, the hollow fiber ceramic support body is regularly bundled, the difference is that the fiber spacing D is 5d o , the fiber arrangement density is 4.7 million / m 2 , 450 / fiber bundle, the hollow fiber ceramic support has an outer diameter of 0.5mm, an inner diameter of 0.1mm, a length of 0.03m, an average pore diameter of 0.35μm, and a porosity of 15%.

[0050] Step 2 Seed coating of hollow fiber bundles

[0051] The prefabricated fiber bundles were saturated with water and placed in the prepared seed crystal suspension. The seed crystals were ball-milled crushed crystal seeds. The particle size of the suspension liquid was 0.3 μm, and the mass fraction of the seed crystals was 5 g / L; The seed crystal suspension was placed in an ultrasonic cleaner for a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com