Method for preparing high-magnetization chitosan nanospheres

A technology of chitosan nanometer and chitosan solution, which is applied in the direction of nanotechnology, microsphere preparation, microcapsule preparation, etc., can solve the problems of wide distribution of magnetic particles, easy aggregation, and difficulty in control, and achieve a simple and repeatable preparation method. Good performance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

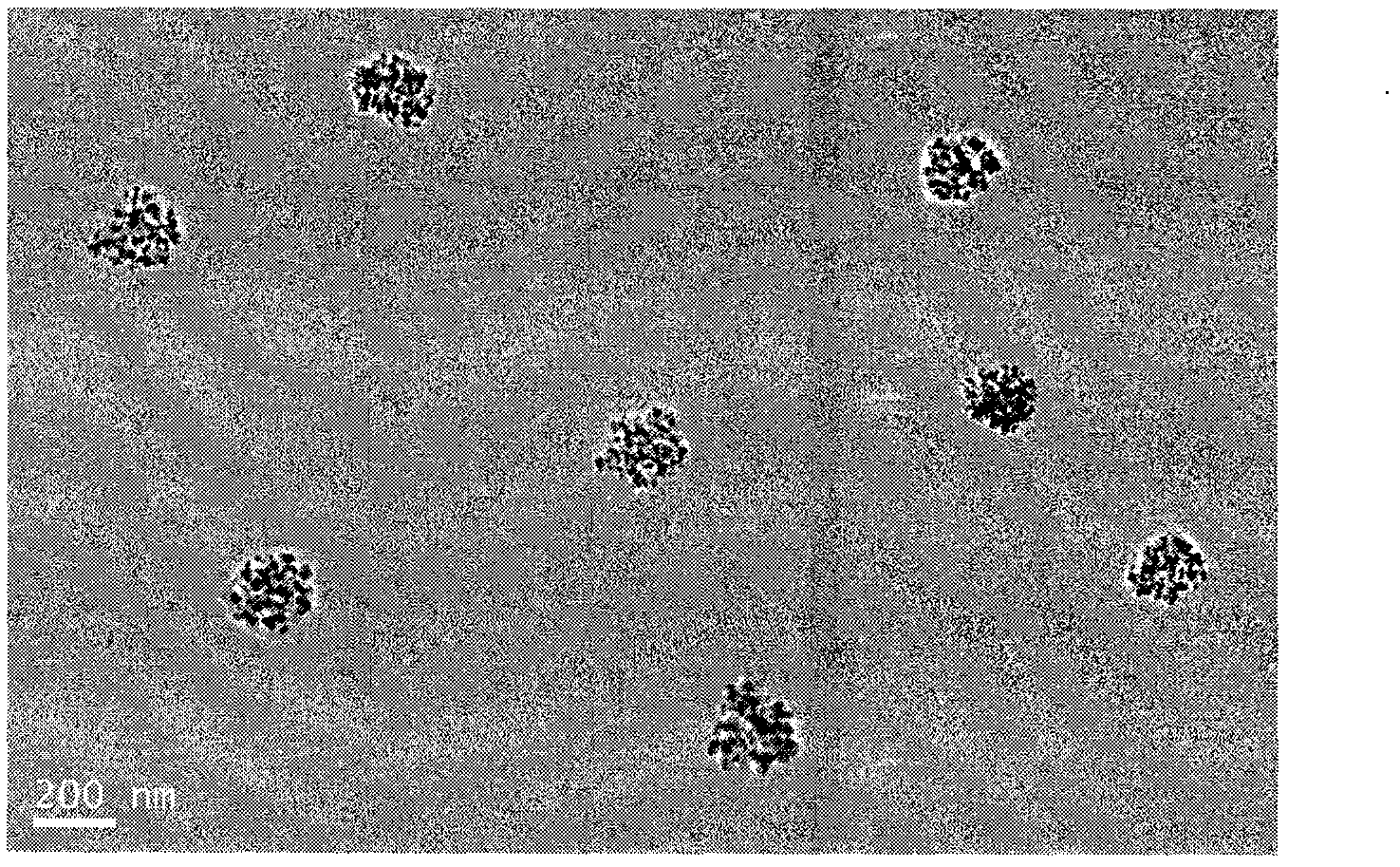

[0019] Mix 1ml of 2% chitosan (Mw 5,000) acetic acid solution and 1ml of 10mg / ml nano ferric oxide particle aqueous solution, ultrasonic for 30 minutes, then slowly add the above solution dropwise to the solution containing 4% Span80 at a certain stirring rate In liquid paraffin, continue to stir for 15 minutes. The obtained primary emulsion was ultrasonicated in an ultrasonic cell breaker for 30 minutes with a power of 500 W. After 15 minutes of ultrasonication, 4 ml of glutaraldehyde solution was added dropwise to make the chitosan nanospheres carry out preliminary cross-linking. After the sonication, the preliminary cross-linked emulsion was transferred to a three-neck flask, and the cross-linking was continued for 12 hours under stirring at a temperature of 40°C. After the reaction is completed, it is centrifuged and washed with petroleum ether, isopropanol, ethanol and pure water to obtain the wrapped Fe 3 o 4 Magnetic chitosan nanoparticles with an average particle siz...

Embodiment 2

[0021] Mix 1ml of 2% chitosan (Mw 50,000) acetic acid solution and 1ml of 20mg / ml nano ferric oxide particle aqueous solution, ultrasonicate for 30 minutes, then slowly add the above solution dropwise to the solution containing 4% Span80 at a certain stirring rate In liquid paraffin, continue to stir for 15 minutes. The obtained primary emulsion was ultrasonicated in an ultrasonic cell breaker for 30 minutes, with a power of 400 W, and after 15 minutes of ultrasonication, 4 ml of glutaraldehyde solution was added dropwise to make the chitosan nanospheres carry out preliminary cross-linking. After the sonication, the preliminary cross-linked emulsion was transferred to a three-necked flask, and the cross-linking was continued for 12 hours under stirring at a temperature of 50°C. After the reaction is completed, the magnetic chitosan nanoparticles are obtained by centrifugal washing with petroleum ether, isopropanol, ethanol and pure water in sequence, and the average particle d...

Embodiment 3

[0023] Mix 1ml of 2% chitosan (Mw 200,000) acetic acid solution and 1ml of 15mg / ml nano ferric oxide particle aqueous solution, ultrasonicate for 30 minutes, then slowly add the above solution dropwise to the solution containing 4% Span80 at a certain stirring rate In the olive oil / petroleum ether (volume ratio 8 / 2), continue stirring for 15 minutes. The obtained primary emulsion was ultrasonicated in an ultrasonic cell breaker for 30 minutes with a power of 500 W. After 15 minutes of ultrasonication, 4 ml of glutaraldehyde solution was added dropwise to make the chitosan nanospheres carry out preliminary cross-linking. After the sonication, the preliminary cross-linked emulsion was transferred to a three-necked flask, and the cross-linking was continued for 24 hours under stirring at a temperature of 40°C. After the reaction is completed, the magnetic chitosan nanoparticles are obtained by centrifugal washing with petroleum ether, isopropanol, ethanol and pure water in sequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com