Graphene oxide/silver phosphate composite visible light catalyst and preparation method thereof

A technology of visible light and silver phosphate, applied in the fields of nanocomposite materials and photocatalysis, can solve the problems of low degradation rate, slow degradation rate of organic dyes, low utilization rate of visible light, etc. The effect of large-scale promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Take 5 mg of graphene oxide and ultrasonically disperse it in 20 mL of deionized water for 3 hours, add 0.2 g of silver acetate to the above solution; dissolve 1.42 g of disodium hydrogen phosphate in 50 mL of deionized water to obtain phosphoric acid with a concentration of 0.2 mol / L Disodium hydrogen phosphate solution; Add the disodium hydrogen phosphate solution dropwise to the prepared graphene oxide / silver acetate solution under magnetic stirring conditions until yellow turbidity appears in the reaction system; After the dropwise addition, continue stirring at room temperature for 15 minutes, pump filtered, the precipitate was washed several times with deionized water, and dried in vacuo.

Embodiment 2

[0022] Take 20 mg of graphene oxide and ultrasonically disperse it in 20 mL of deionized water for 3 hours, add 0.4 g of silver acetate to the above solution; dissolve 2.84 g of disodium hydrogen phosphate in 50 mL of deionized water to obtain phosphoric acid with a concentration of 0.4 mol / L Disodium hydrogen phosphate solution; Add the disodium hydrogen phosphate solution dropwise to the prepared graphene oxide / silver acetate solution under magnetic stirring conditions until yellow turbidity appears in the reaction system; After the dropwise addition, continue stirring at room temperature for 15 minutes, pump filtered, the precipitate was washed several times with deionized water, and dried in vacuo.

Embodiment 3

[0024] Take 50 mg of graphene oxide and ultrasonically disperse it in 20 mL of deionized water for 4 hours, add 0.6 g of silver acetate to the above solution; dissolve 7.1 g of disodium hydrogen phosphate in 50 mL of deionized water to obtain phosphoric acid with a concentration of 1 mol / L Disodium hydrogen phosphate solution; Add the disodium hydrogen phosphate solution dropwise to the prepared graphene oxide / silver acetate solution under magnetic stirring conditions until yellow turbidity appears in the reaction system; After the dropwise addition, continue stirring at room temperature for 15 minutes, pump filtered, the precipitate was washed several times with deionized water, and dried in vacuo.

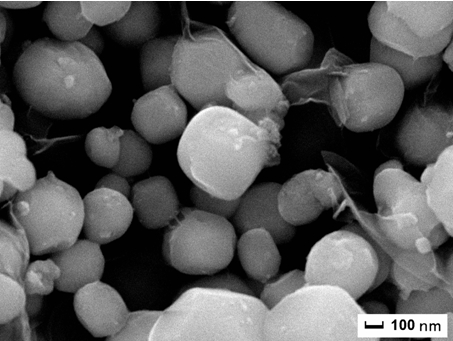

[0025] figure 1 The scanning electron microscope picture of the graphene oxide / silver phosphate nanocomposite visible light catalyst prepared for this embodiment, we can clearly see that the obtained silver phosphate is wrapped by a thin layer of graphene oxide from the figure, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com