Mica tape for motor and preparation method of mica tape

A technology of mica tape and mica paper, applied in chemical instruments and methods, epoxy resin glue, adhesive types, etc., can solve the problems of difficult motor insulation and flame retardancy, large motor heat generation, poor aging resistance, etc. Improve crosslinking density, reduce dielectric loss, good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] According to the mica tape of the present embodiment obtains through the following steps:

[0026] 1. Preparation of adhesive

[0027] (1), synthetic carboxyl-terminated hyperbranched polyester resin: put 0.1mol trimesic acid, 0.1mol ethylene glycol and 0.2g p-toluenesulfonic acid into a three-necked flask, connect the water separator, thermometer and stirring device, put The temperature of the computer microwave reactor was controlled at 180° C., and the power was set to 1000 watts to react for 6 hours to obtain a carboxyl-terminated hyperbranched polyester resin with a molecular weight of 19500 (number average).

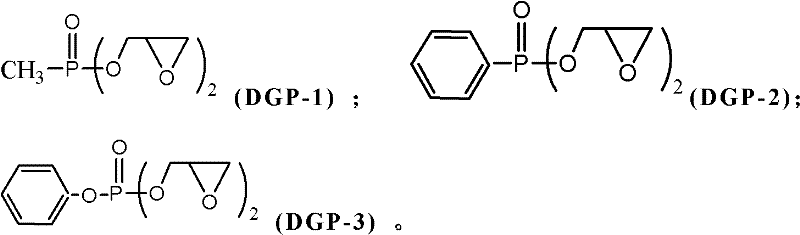

[0028] (2), preparation adhesive: get step (1) gained hyperbranched polyester resin 10 parts, bisphenol A type epoxy resin (commercial code is E51) 40 parts, acetone 25 parts, butanol 25 parts, aluminum acetylacetonate 0.1 40 parts and 40 parts of phosphorus-containing epoxy resin (DGP-1) are mixed evenly to obtain the adhesive.

[0029] 2. Making mica tap...

Embodiment 2

[0032] According to the mica tape of the present embodiment obtains through the following steps:

[0033] 1. Preparation of adhesive

[0034] (1), synthesis of carboxyl-terminated hyperbranched polyester resin: put 0.1mol trimellitic acid, 0.1 butanediol and 0.3g p-toluenesulfonic acid into a three-necked flask, connect the water separator, thermometer and stirring device, and put the computer The temperature of the microwave reactor was controlled at 200° C., and the power was set to 1100 watts to react for 6 hours to obtain a carboxyl-terminated hyperbranched polyester resin with a molecular weight of 18,000 (number average).

[0035] (2), preparation adhesive: get 15 parts of carboxyl-terminated hyperbranched polyester resins obtained in step (1), 30 parts of bisphenol A type epoxy resins (commercial code name is E54), 10 parts of acetone, 20 parts of butanol, xylene 50 parts, 0.3 parts of chromium acetylacetonate, and 60 parts of phosphorus-containing epoxy resin (DGP-2) ...

Embodiment 3

[0039] According to the mica tape of the present embodiment obtains through the following steps:

[0040] 1. Preparation of adhesive

[0041] (1), synthetic carboxyl-terminated hyperbranched polyester resin: 0.11mol trimellitic anhydride, 0.05mol propylene glycol, 0.05mol ethylene glycol and 0.5g p-toluenesulfonic acid are put into a three-necked flask, connected to a water separator, a thermometer and a stirring device, The temperature of the computer microwave reactor was controlled at 150° C., and the power was set to 1100 watts to react for 5 hours to obtain a carboxyl-terminated hyperbranched polyester resin with a molecular weight of 10,000 (number average).

[0042] (2), preparation adhesive: get 15 parts of carboxyl-terminated hyperbranched polyester resins obtained in step (1), 60 parts of bisphenol A type epoxy resins (commercial code name is CYD128), 30 parts of acetone, 30 parts of butanol, 40 parts of toluene parts, 0.5 parts of chromium isooctanoate, and 90 parts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| breakdown voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com