Method for preparing organic micro/nano structure by liquid phase chemical reaction method and patterning in situ

A technology of liquid-phase chemical reaction and micro-nano structure, applied in the direction of micro-structure technology, micro-structure device, etc., can solve problems such as unsatisfactory solubility, uneconomical, limited research on internal scientific problems, and large-scale device preparation and application. To achieve the effect of simple and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

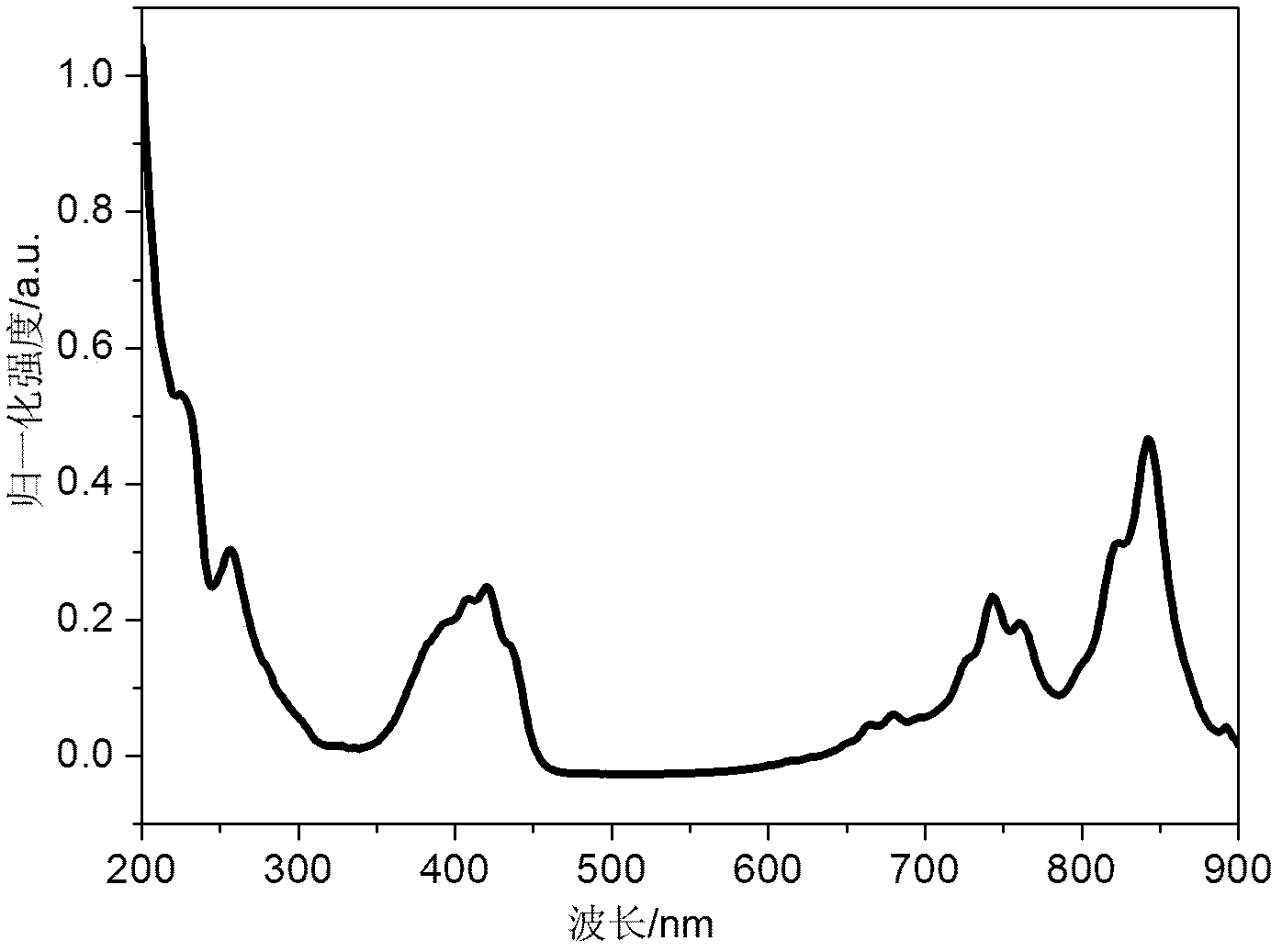

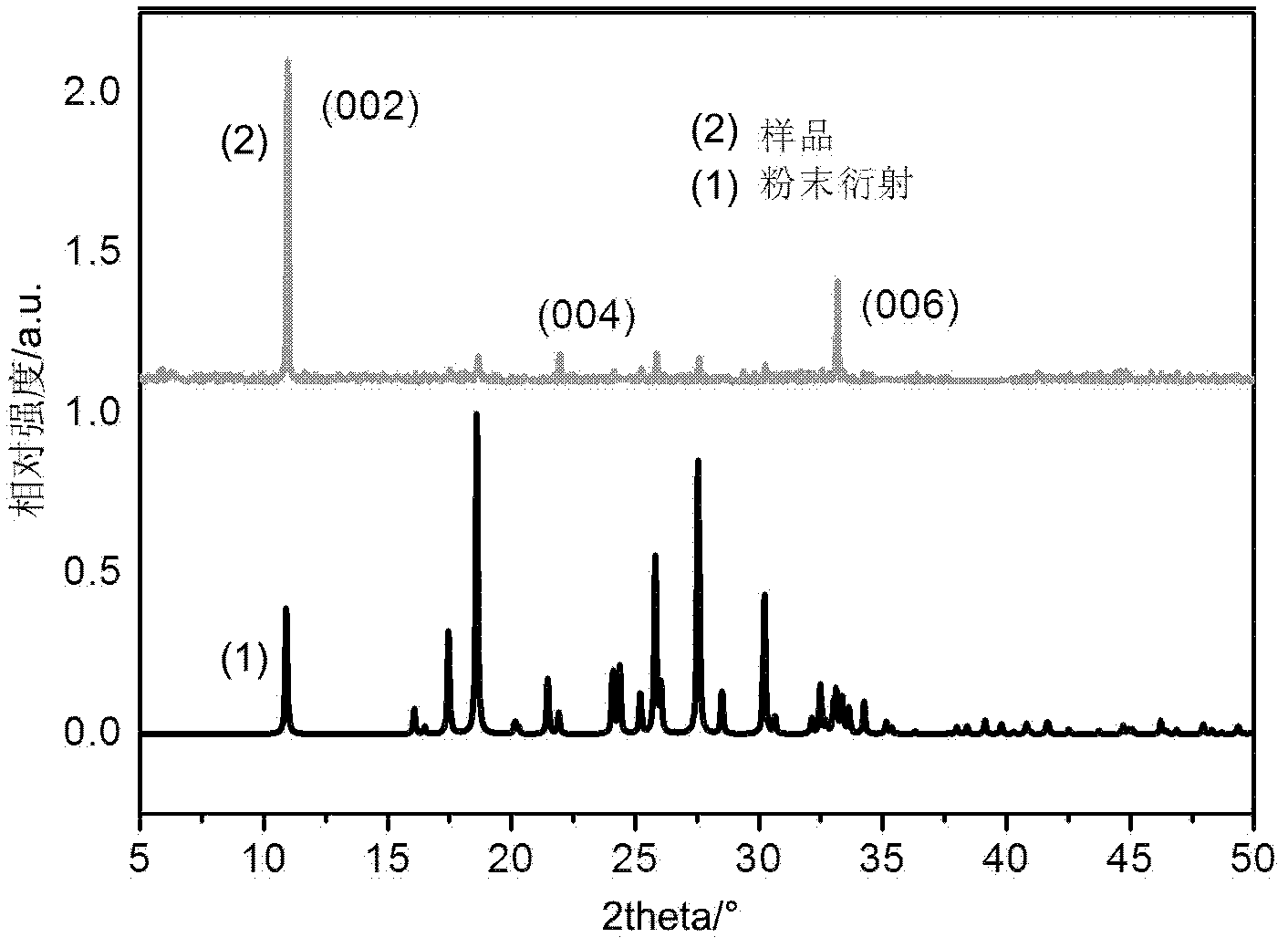

[0049] Preparation of Anionic Radicals of 7,7,8,8-Tetracyanoquinodimethane (TCNQ) and Controllable Preparation of Micro-Nano Structures

[0050] Preparation of anionic radical salts:

[0051] Add 10g of TCNQ (structure as shown in structural formula 1) into 1000ml of high-purity acetonitrile solution, place it in a round bottom flask for reflux condensation and heat until the acetonitrile is almost boiling. Then the lithium iodide (LiI) that takes 20g is dissolved in the acetonitrile of 50ml, and as the case may be set as heating to promote dissolving, then this solution is added rapidly in the acetonitrile solution of TCNQ while hot, under the situation that solution is nearly boiling, continue to stir About 4 hours. After that, it was filtered with filter paper while it was still hot to obtain a dark red needle-like solid, which was washed with high-purity acetonitrile for 3 to 4 times until the filtrate was bright green. Then wash the solid with a large amount of diethyl ...

Embodiment 2

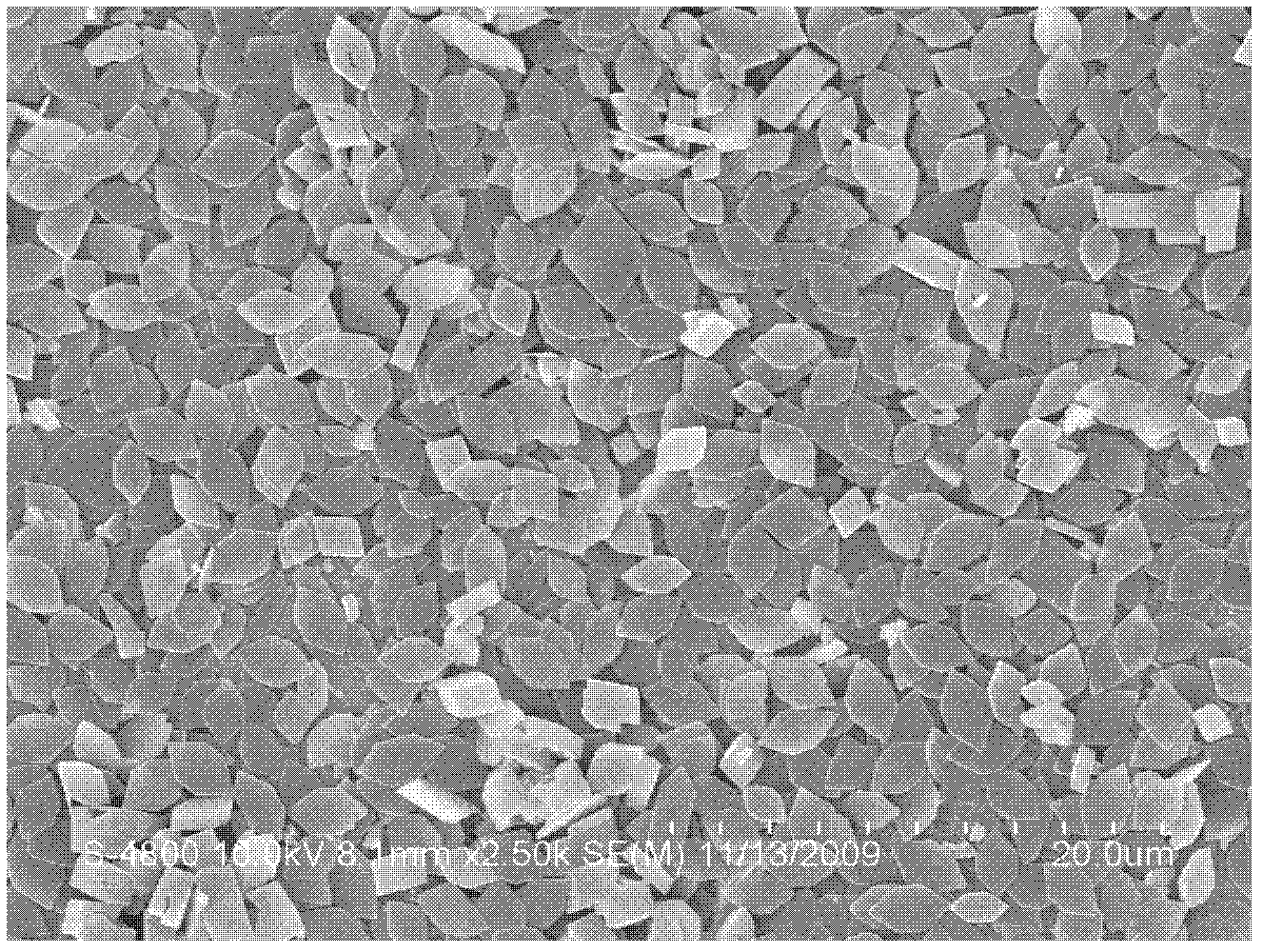

[0066] Embodiment 2, using TCNQ anion radicals to carry out in situ reaction to prepare patterned nanostructures:

[0067]First, weigh an appropriate amount of LiTCNQ to prepare an acetonitrile solution of about 1 mM, dip the patterned Cu electrode that has been washed and surface oxidized in advance, and store it in an airtight and dark place for a certain period of time (30min to 4h, the length of time depends on Determine the size of the reaction degree, see the detailed description below), then take it out, wash it repeatedly with acetonitrile, and dry it in vacuum to obtain a patterned CuTCNQ arrayed device (sample 6#) grown in situ. The corresponding SEM images are shown in Figure 8 (reaction 30min), Figure 9 (1 hour reaction) and Figure 10 (response 4 hours), Figure 11 ( Figure 10 Enlarged photo of the middle channel). Figure 12 Photograph of a large-area arrayed electrode substrate. Figure 13 Then it is the laser confocal microscope Raman spectrum of the o...

Embodiment 3

[0069] Embodiment 3, the controllable preparation of the anion free radical of the prepared perylene imide and its nanostructure

[0070] Preparation of anion radicals:

[0071] Get 3.9mg of perylene imide solid (structure as shown in structural formula 2) and 174mg sodium thiothionite (the amount of reducing agent can be changed according to needs), 400mg sodium hydroxide flake solid is placed in a 50ml reaction there-necked flask, Seal and connect the double-row tube, vacuumize, wash with high-purity nitrogen for 2 to 3 times, and then fill the three-necked bottle with nitrogen. Pipette 20ml of tetrahydrofuran or acetonitrile solution deoxygenated by nitrogen bubbling into the system, stir for 20min under nitrogen protection, then add 5ml of secondary water deoxygenated by nitrogen in advance, and continue stirring. As the reaction progressed, the color of the solution changed from a dark red cloudy solution to a magenta clear solution, indicating the formation of dianions....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com