Modified phenolic resin for dry material, preparation method for modified phenolic resin and dry material

A technology of phenolic resin and dry material, applied in the field of phenolic resin, can solve the problems of carbon increase and high carbon content, and achieve the effects of low flexural strength, improved compressive strength and maintenance of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The invention provides a kind of preparation method of modified phenolic resin for dry type material, comprising the following steps:

[0021] a) the phenolic compound and the aldehyde compound react under the action of an acidic catalyst to obtain a phenolic resin;

[0022] b) adding a modifying agent to the phenolic resin obtained in the step a), and reacting to obtain a modified phenolic resin for dry-type materials, and the modifying agent is rosin resin waste, coumarone resin waste or epoxy resin waste .

[0023] The invention uses rosin resin waste, coumarone resin waste or epoxy resin waste as a modifier to modify the phenolic resin, the preparation method is simple, the modifier is cheap and easy to obtain, and the cost is reduced while ensuring the performance of the phenolic resin .

[0024] In the present invention, phenolic compounds and aldehyde compounds are used as raw materials to react under the action of an acidic catalyst to obtain phenolic resins. ...

Embodiment 1

[0047] Add phenol, formaldehyde, and hydrochloric acid into the reaction kettle according to the mass ratio of 1:0.33:0.01, heat and stir to 75°C, and after constant temperature reaction for 1.5h, add formaldehyde to make the mass ratio of phenol to 0.85:1, 1h After adding the formaldehyde, the temperature was raised to 100° C., and the phenolic resin was obtained by constant temperature reaction for 1.5 hours; the rosin resin waste material that accounted for 40% of the total mass of phenol and formaldehyde was added to the phenolic resin, and the constant temperature was reacted for 1 hour, and then dehydrated under normal pressure. The modified phenolic resin was obtained after discharge, wherein the waste rosin resin was purchased from Hengshui Zehao Rubber Chemical Co., Ltd.

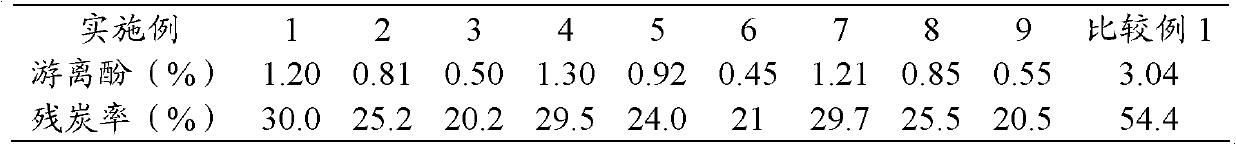

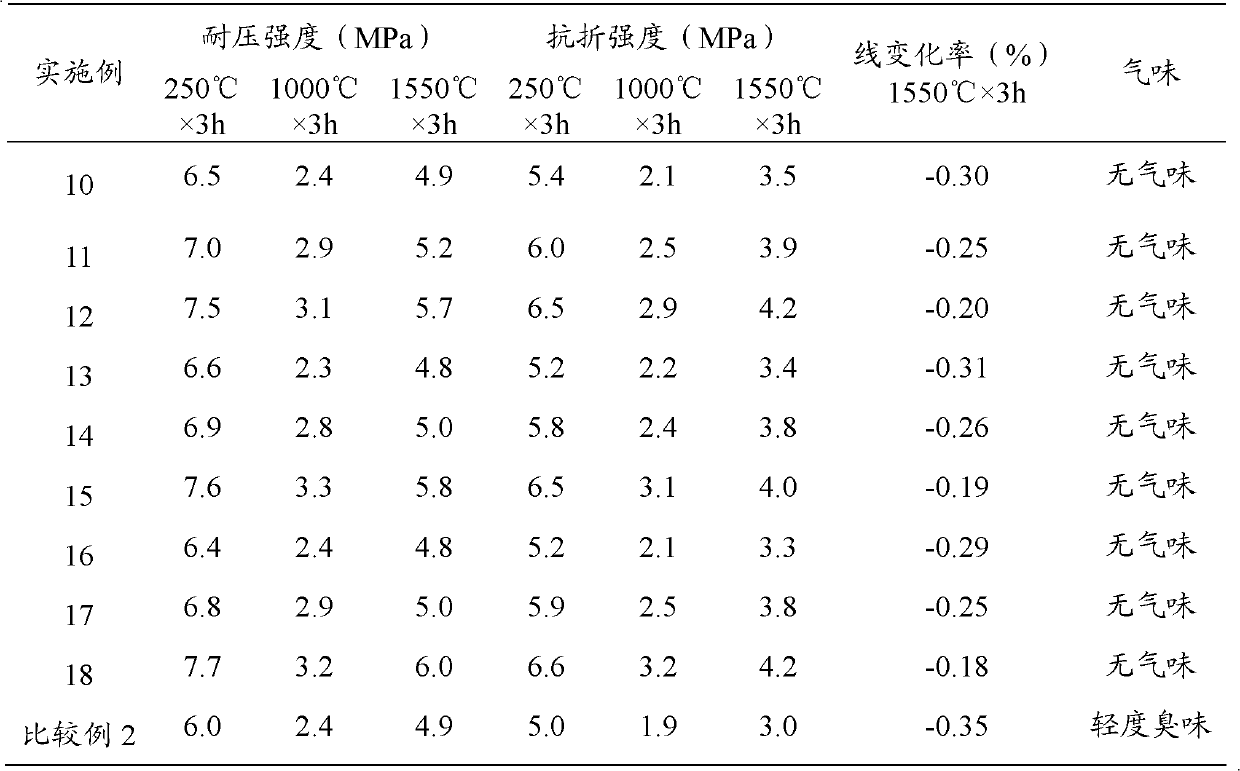

[0048] The free phenol content and carbon residue rate of the modified phenolic resin were tested, and the results are shown in Table 1. Table 1 shows the test results of the phenolic resin provided ...

Embodiment 2

[0050] Add phenol, formaldehyde, and hydrochloric acid into the reaction kettle according to the mass ratio of 1:0.33:0.01, heat and stir to 75°C, after constant temperature reaction for 1.5h, add formaldehyde to make the mass ratio of phenol to 0.8:1, 1h After adding formaldehyde, the temperature was raised to 100° C., and the constant temperature reaction was carried out for 2 hours to obtain the phenolic resin; the rosin resin waste which accounted for 60% of the total mass of phenol and formaldehyde was added to the phenolic resin, and the constant temperature reaction was carried out for 1 hour. The modified phenolic resin was obtained after the raw material, and the rosin resin waste was purchased from Jinan Zhongyan Chemical Development Co., Ltd.

[0051] The free phenol content and carbon residue rate of the modified phenolic resin were tested, and the results are shown in Table 1. Table 1 shows the test results of the phenolic resin provided in the examples and compara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com