Method for preparing copper-zinc-tin-sulfur light absorbing layer of film solar batter

A light-absorbing layer, copper-zinc-tin-sulfur technology, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of difficult control of high temperature and high pressure, restrictions on large-scale promotion, and restrictions on large-scale production, so as to improve safety, Widening of large-scale industrialization, the effect of solving cost and environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

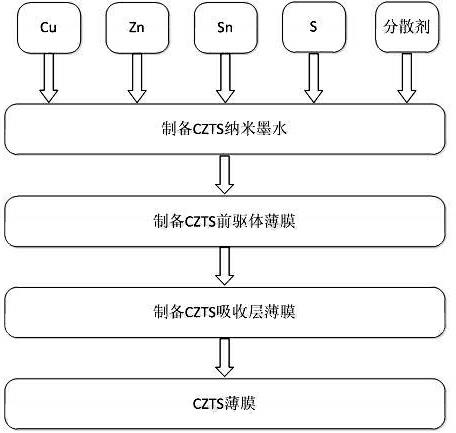

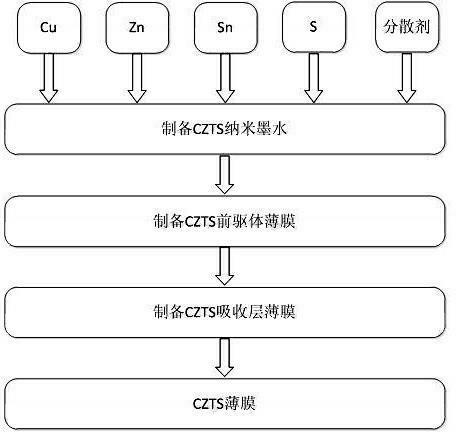

[0024] (1) According to the molecular formula Cu 2 ZnSnS 4 The molar ratio of Cu, Zn, Sn and S weighed 1.271g of Cu, 0.654g of Zn, 1.187g of Sn and 1.283g of S, mixed them, added 20mL of ethanol and mixed them well, then put them in a ball mill Ball milling for 10 hours, ball milling to prepare CZTS nano-ink;

[0025] (2) Spin-coat the prepared CZTS nano-ink onto the cleaned soda-lime glass, place it on an electric furnace and dry it at 50°C for 10 minutes, remove the dispersant, and prepare a CZTS precursor film;

[0026] (3) Place the prepared CZTS precursor film in a tube furnace, and vulcanize it in sulfur vapor to prepare the CZTS film; put an appropriate amount of elemental sulfur in the graphite box, and place the CZTS precursor film substrate material on In the graphite box, place the graphite box at the center of the tube furnace, feed nitrogen gas with a flow rate of 50 sccm, raise the temperature to 250 °C at a rate of 10 °C / min, keep it for 20 minutes, and then i...

Embodiment 2

[0029] (1) According to the molecular formula Cu 2 Zn 1.2 SnS 4 The molar ratio of Cu, Zn, Sn and S in the formula weighs 1.271g of Cu, 0.785g of Zn, 1.187g of Sn and 1.283g of S, mixes them, adds 40mL of butanol and mixes them well, then puts them in a ball mill jar Carry out ball milling for 20 hours, and prepare CZTS nano-ink by ball milling;

[0030](2) Spray the prepared CZTS nano ink onto the cleaned copper sheet, place it on an electric furnace and dry it at 100°C for 30 minutes, remove the dispersant, and prepare a CZTS precursor film;

[0031] (3) Place the prepared CZTS precursor film in a tube furnace, and vulcanize it in sulfur vapor to prepare the CZTS film; put an appropriate amount of elemental sulfur in the graphite box, and place the CZTS precursor film substrate material on In the graphite box, place the graphite box at the center of the tube furnace, feed argon gas with a flow rate of 30 sccm, raise the temperature to 250 °C at a rate of 15 °C / min, keep i...

Embodiment 3

[0034] (1) According to the molecular formula Cu 1.8 Zn 1.2 sn 0.9 S 4 In the molar ratio of Cu, Zn, Sn and S, weigh 1.144g of Cu, 0.785g of Zn, 1.068g of Sn and 1.283g of S, mix them, add 25mL of 2-methoxyethanol and mix well, then place Carry out ball milling in the ball mill tank for 30 hours, and prepare CZTS nano-ink by ball milling;

[0035] (2) Inkjet print the prepared CZTS nano-ink on the polyimide that has been cleaned, place it on an electric furnace and dry it at 80°C for 15 minutes, remove the dispersant, and prepare a CZTS precursor film;

[0036] (3) Place the prepared CZTS precursor film in a tube furnace, and vulcanize it in sulfur vapor to prepare the CZTS film; put an appropriate amount of elemental sulfur in the graphite box, and place the CZTS precursor film substrate material on In the graphite box, place the graphite box at the center of the tube furnace, feed nitrogen gas with a flow rate of 40 sccm, raise the temperature to 300 °C at a rate of 25 °...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com