Method for preparing complete feed through probiotics asynchronous high-low-moisture fermentation

A technology of full-price feed and probiotics, which is applied in the direction of animal feed, animal feed, additional food elements, etc., to achieve the effect of reducing lactic acid content, reducing the ratio of feed to meat, and improving the nutritional value of feed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

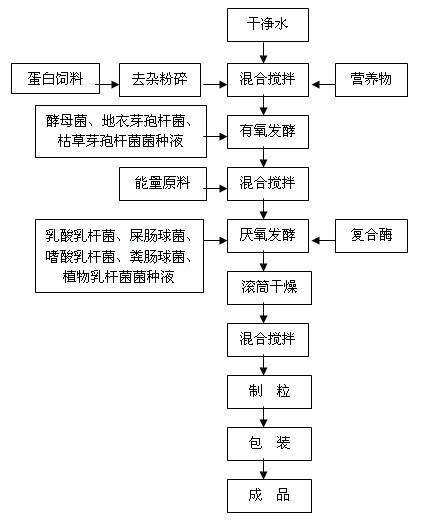

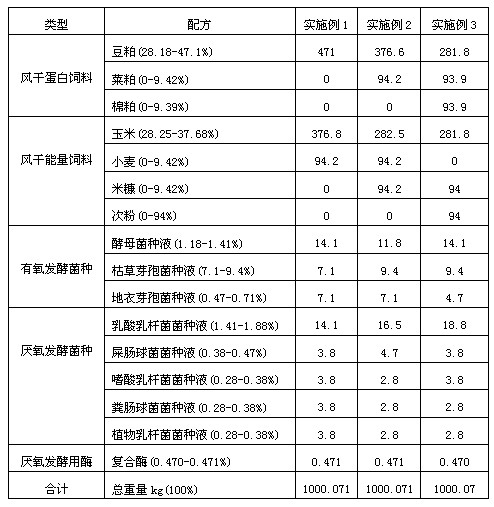

[0034] Embodiment one: if figure 1 and figure 2 As shown, the specific steps included in this process are as follows.

[0035] (1) First remove impurities and crush 471kg of soybean meal, add glucose and mineral salt, mix with 565.2kg of clean water, and adjust the water content to 60%.

[0036] (2) Next, insert 14.1 kg of yeast seed liquid, 7.1 kg of subtilis seed liquid, and 7.1 kg of licheniformis seed liquid, feed oxygen and ferment at 35° C. for 96 hours.

[0037] (3) Then 376.8 kg of corn and 94.2 kg of wheat were removed from impurities, crushed, mixed and stirred, mixed into the above-mentioned fermented soybean meal, and the water content was adjusted to 25%.

[0038] (4) Add 14.1kg of lactobacillus seed solution, 3.8kg of Enterococcus faecium seed solution, 3.8kg of Lactobacillus acidophilus seed solution, 3.8kg of Enterococcus faecalis seed solution and 3.8 kg of Lactobacillus plantarum seed solution kg, add 0.471 kg of amylase and protease at the same time, and...

Embodiment 2

[0040] Embodiment two: if figure 1 and figure 2 As shown, the specific steps included in this process are as follows.

[0041] (1) Remove impurities and crush 376.6kg of soybean meal and 94.2kg of rapeseed meal, then add glucose and mineral salt, mix and stir with 564.9kg of clean water, and adjust the water content to 70%.

[0042] (2) Next, 11.8 kg of yeast seed liquid, 9.4 kg of subtilis seed liquid, and 7.1 kg of licheniformis seed liquid were inserted, and oxygen was introduced to ferment at 45° C. for 12 hours.

[0043] (3) Then 282.5 kg of corn, 94.2 kg of wheat, and 94.2 kg of rice bran were removed and pulverized, and mixed into the above-mentioned fermented soybean meal and rapeseed meal, and the water content was adjusted to 35%.

[0044](4) Add 16.5kg of lactobacillus seed solution, 4.7kg of Enterococcus faecium seed solution, 2.8kg of Lactobacillus acidophilus seed solution, 2.8kg of Enterococcus faecalis seed solution and 2.8 kg of Lactobacillus plantarum seed...

Embodiment 3

[0046] Embodiment three: as figure 1 and figure 2 As shown, the specific steps included in this process are as follows.

[0047] (1) Remove impurities and crush 281.8kg of soybean meal, 93.9kg of rapeseed meal and 93.9kg of cotton meal, then add glucose and mineral salt, mix and stir with 563.6kg of clean water, and adjust the water content to 65%.

[0048] (2) Next, insert 14.1kg of yeast seed liquid, 9.4kg of subtilis seed liquid, and 4.7kg of licheniformis seed liquid, feed oxygen and ferment at 39°C for 48 hours.

[0049] (3) Then 281.8 kg of corn, 94 kg of secondary flour, and 94 kg of rice bran were removed and crushed, and mixed into the above-mentioned fermented soybean meal, rapeseed meal, and cotton meal, and the water content was adjusted to 30%.

[0050] (4) Add 18.8kg of lactobacillus seed solution, 3.8kg of Enterococcus faecium seed solution, 3.8kg of Lactobacillus acidophilus seed solution, 2.8kg of Enterococcus faecalis seed solution and 2.8 kg of Lactobacil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com