Amino acid and glucose injection packaged by dual-chambered bag, and preparation method of the injection

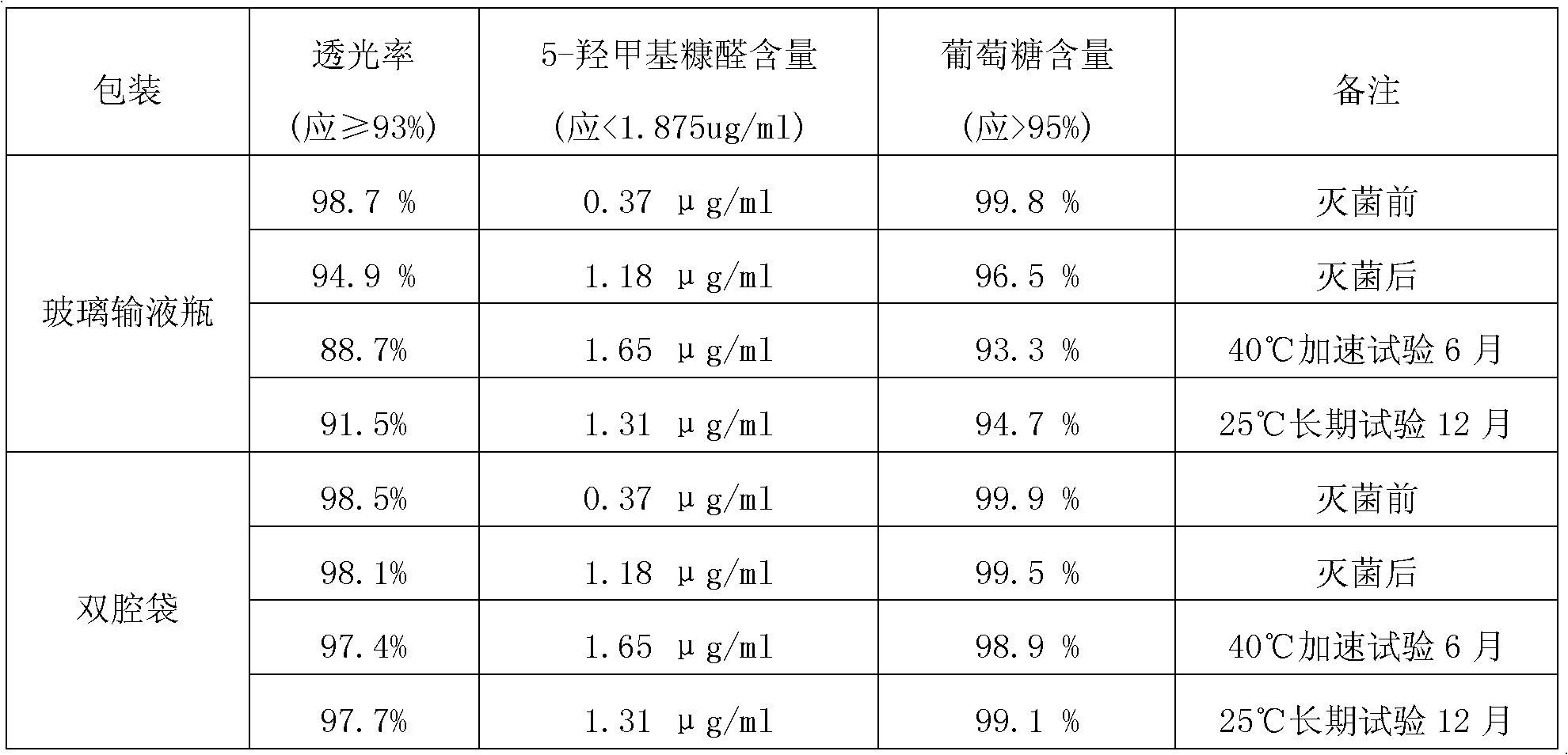

A glucose injection and glucose solution technology, which is applied in packaging, food packaging, pharmaceutical packaging, etc., can solve the problems of increasing related substances, deepening the color, and decreasing the content of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0159] The raw material composition of amino acid solution is as follows

[0160] Leucine 4.17kg

[0161] Isoleucine 1.87kg

[0162] Lysine acetate 4.13kg

[0163] Methionine 1.17kg

[0164] Histidine 2kg

[0165] Tyrosine 0.116kg

[0166] Alanine 2.07kg

[0167] Glycine 3.57kg

[0168] Aspartic acid 1.27kg

[0169] Glutamic acid 2.17kg

[0170] Proline 1.10kg

[0171] Phenylalanine 3.11kg

[0172] Threonine 2.17kg

[0173] N-acetyl L-tryptophan 0.52kg

[0174] Valine 1.50kg

[0175] Serine 0.73kg

[0176] Arginine 2.63kg

[0177] Cysteine Hydrochloride 0.48kg

[0178] Sodium metabisulfite 1kg

[0179] Water for injection 500kg

[0180] The raw material composition of glucose solution is as follows:

[0181] Glucose 37.5kg

[0182] Water for injection 250l

[0183] The structure of the double chamber bag is as follows:

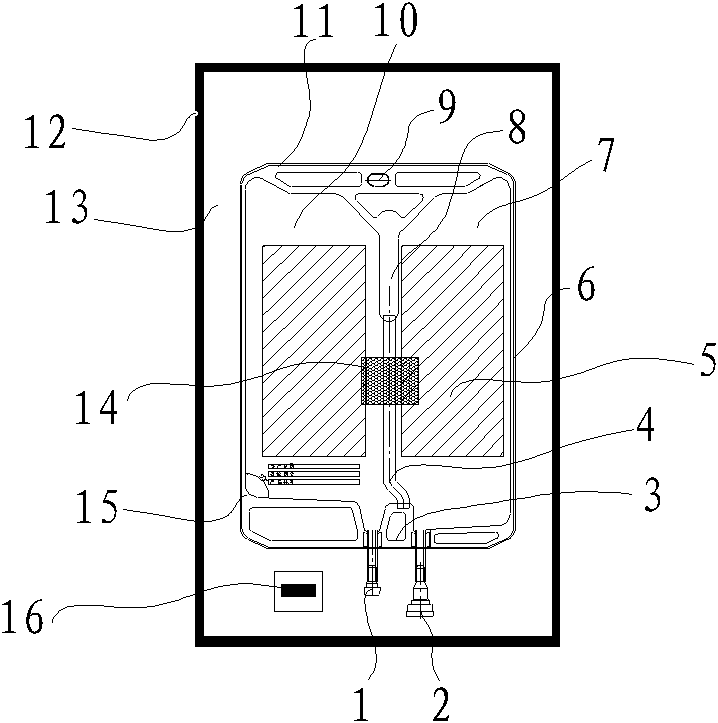

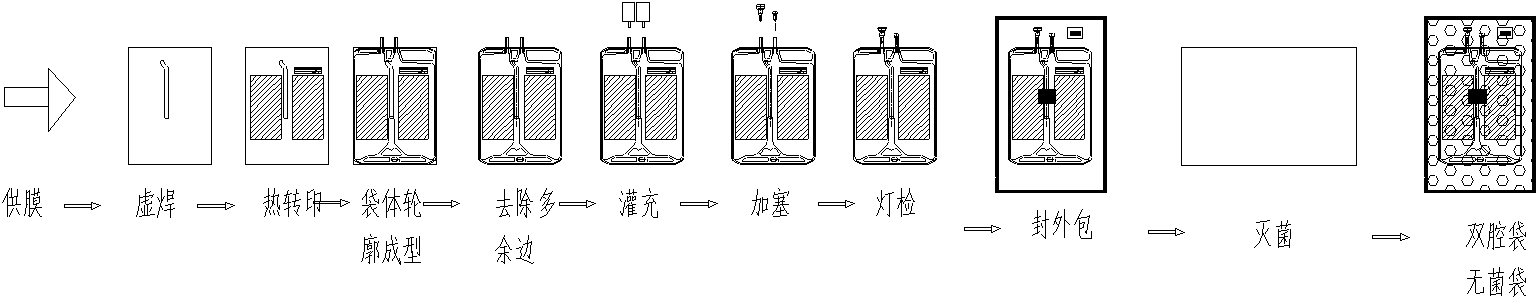

[0184] A double-chamber aseptic bag, drug dosing plug 1, drug infusion plug 2, protection table 3, independent chamber thermal transfer...

Embodiment 2

[0191] The raw material composition of amino acid is as follows:

[0192] Arginine Hydrochloride 20kg

[0193] Water for injection 500kg

[0194] The raw material composition of glucose solution is as follows:

[0195] Glucose 37.5kg

[0196] Water for injection 250l

[0197] The structure and preparation method of the double-cavity bag are the same as in Example 1.

[0198] The preparation method of the amino acid glucose injection packaged in a double-cavity bag is as follows: take glucose and water for injection to prepare a solution with a concentration of 10%-15%, absorb the solution with 0.1%-0.15% activated carbon, and then decarbonize it with a titanium rod. 0.2μm~0.4μm microporous membrane filtration; take amino acid and water for injection to make a solution, absorb the solution with 0.1%~0.15% activated carbon, then decarbonize with titanium rod, filter through 0.2μm~0.4μm microporous membrane, and finally carry out Nitrogen filling for 15-20 minutes; fill the tw...

Embodiment 3

[0200] The raw material composition of amino acid is:

[0201] Leucine 2.5kg

[0202] Isoleucine 2.7kg

[0203] Lysine acetate 2.5kg

[0204] Methionine 1.3kg

[0205] Histidine 1.3kg

[0206] Tyrosine 0.13kg

[0207] Alanine 1.3kg

[0208] Glycine 5.5kg

[0209] Aspartic acid 1kg

[0210] Glutamic acid 2.7kg

[0211] Proline 0.8kg

[0212] Phenylalanine 4kg

[0213] Threonine 1.3kg

[0214] N-acetyl L-tryptophan 0.7kg

[0215] Valine 1kg

[0216] Serine 1kg

[0217] Arginine 1.5kg

[0218] Cysteine Hydrochloride 0.6kg

[0219] Sodium metabisulfite 0.8kg

[0220] Water for injection 300kg

[0221] The raw material composition of glucose is:

[0222] Glucose 55kg

[0223] Water for injection 150l

[0224] The structure and preparation method of the double-cavity bag are the same as in Example 1.

[0225] The preparation method of the amino acid glucose injection packaged in a double-cavity bag is as follows: take glucose and water for injection to make a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com