Method for preparing monodisperse submicron polystyrene spheres by intermediate-and low-temperature solvent thermal process

A technology of low-temperature solvothermal method and polystyrene balls, which is applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problem of narrow particle size control range, large particle size, and increased difficulty in particle separation and purification and other problems, to achieve the effect of good monodispersity, simple preparation process, and easy mass production and scale-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

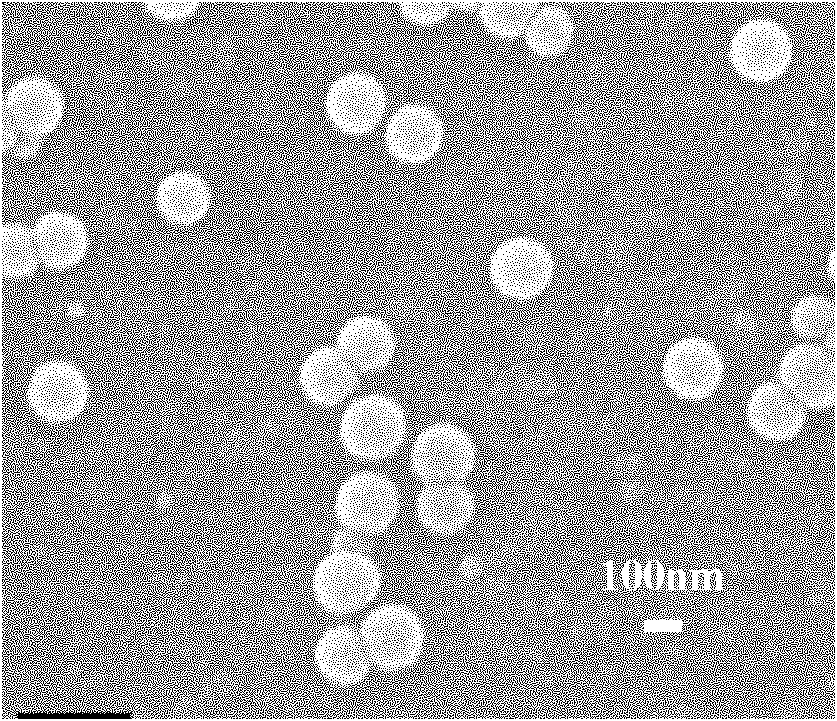

[0041] Concentration is that the styrene (St) monomer of 0.063mol / L is dissolved in the ethanol and the water mixed solution that mass ratio is 4 / 1, stirs, in solution, add the PVP that concentration is 5.0g / L as stabilizer, and Stir until the solution is clear, then add AIBA with 1% of the monomer mass as an initiator, and stir until it is completely dissolved; then transfer the resulting solution to a high-pressure reaction kettle, and put the kettle into an oven to maintain at 80°C After 5 hours, cool naturally in the air to room temperature, centrifuge the white emulsion in the kettle, disperse it with absolute ethanol and then centrifuge it, repeat this cycle for 3 times, and vacuum-dry the obtained solid in a vacuum oven at 50°C to obtain the product. Its scanning electron microscope picture is figure 1, The particle size is 112nm, and the dispersion coefficient σ is 12.5%.

Embodiment 2

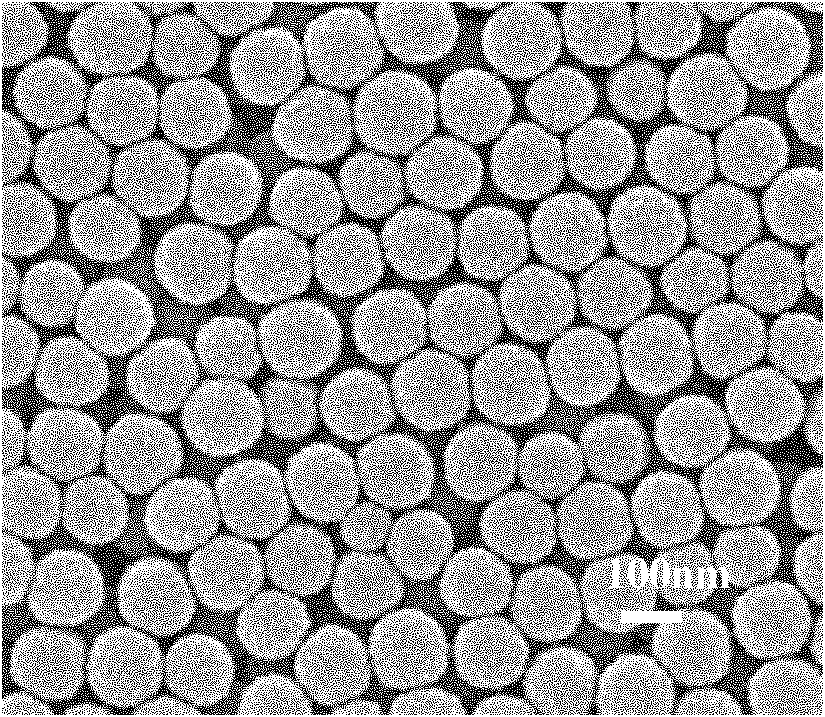

[0043] Concentration is that the styrene (St) monomer of 0.1mol / L is dissolved in the ethanol and water mixed solution that mass ratio is 4 / 1, stirs, and in solution, add the PVP that concentration is 5.0g / L as stabilizer, and Stir until the solution is clear, then add AIBA with 1% of the monomer mass as an initiator, and stir until it is completely dissolved; then transfer the resulting solution to a high-pressure reaction kettle, and put the kettle into an oven to maintain at 80°C After 5 hours, cool naturally in the air to room temperature, centrifuge the white emulsion in the kettle, disperse it with absolute ethanol and then centrifuge it, repeat this cycle for 3 times, and vacuum-dry the obtained solid in a vacuum oven at 50°C to obtain the product. Its scanning electron microscope picture is figure 2 , The particle size is 225nm, and the dispersion coefficient σ is 5.3%.

Embodiment 3

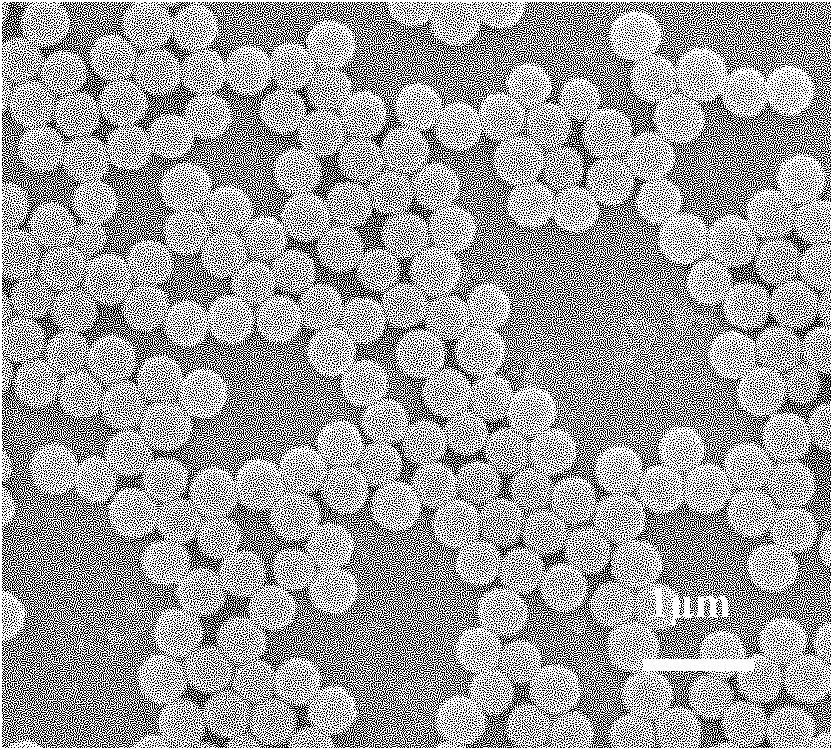

[0045] Concentration is that the styrene (St) monomer of 0.48mol / L is dissolved in the ethanol and the water mixed solution that mass ratio is 4 / 1, stirs, in solution, add the PVP that concentration is 5.0g / L as stabilizer, and Stir until the solution is clear, then add AIBA with 1% of the monomer mass as an initiator, and stir until it is completely dissolved; then transfer the resulting solution to a high-pressure reaction kettle, and put the kettle into an oven to maintain at 80°C After 5 hours, cool naturally in the air to room temperature, centrifuge the white emulsion in the kettle, disperse it with absolute ethanol and then centrifuge it, repeat this cycle for 3 times, and vacuum-dry the obtained solid in a vacuum oven at 50°C to obtain the product. Its scanning electron microscope picture is image 3 , The particle size is 472nm, and the dispersion coefficient σ is 3.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com